Vapor: Pressure, Permeance, and Permeability

High-performance builder Ben Bogie presents a few mental visuals to help understand that elusive moisture menace.

Welcome to this month’s installment of “Ben bumbles an analogy.” This is the place where I attempt to take something that people go to graduate school to understand, chop it into pieces based on half-informed Internet searches and a few well-placed phone calls, and hopefully squeeze out some kernel of shareable knowledge. So hop in, let’s take this ride . . .

Big perm

I’m feeling masochistic this month and going straight for the cliff dive. We’re talking vapor, permeance, permeability, wet cups, dry cups, rates, pressures, oh my! I’m not going to go into why water vapor is something to pay attention to—suffice to say, moisture causes problems—but we’re going to talk about how vapor does its thing. It’s a convoluted and nuanced subject that often leaves me—and, as I discovered while researching this post, many others—flummoxed.

Back to pasta

For a brief explanation of water vapor, I’ll revisit my boiling pasta analogy. Essentially, vapor is the gas form of what we use to cook pasta. The steam coming off the pot is vapor in a concentration so strong we can see it. Ultimately, it spreads out to the point that we can’t see it, but it’s still there—all around us, bouncing off and through everything. Unless we’re in the vacuum of aerospace, there’s water vapor in some quantity everywhere. We measure it with the common metric of humidity, which is a measurement of the relative vapor pressure in a given space. If we put a lid on our pot of pasta, the space under that lid is going to have a higher vapor pressure than the space outside of it—you with me?

Vapor is like a box of bouncy balls

Vapor always wants to move from more to less, it’s one of those laws of thermodynamics, I’m not going to pretend to know which one, nor will I Google it and act like I knew. It’s a fundamental action of nature. In my mind, it’s like this: Take a cardboard box, throw a handful of rubber bouncy balls in it, close it up, and start shaking it. This is what vapor is doing around us all the time. The more balls we add to the box, the higher the vapor pressure. Now, if we make a hole in this box and continue shaking it, eventually some of those balls are going to make their way out. This is permeance. The more holes, the more permeance and vice-versa—sort of.

Extra-thick cardboard

So, let’s look at one side of our box (hopefully your imagination has punched a few holes through it). The number of holes in relation to the size of the piece of cardboard is the vapor permeance—think of it like DPI (dots per inch) with printers. The more holes per given area, the higher the permeance. I’m simplifying things a bit; real science would also account for the level of pressure and the length of time vapor is allowed to escape.

Back to the box . . . with the same number of holes and shaken at the same speed, but now imagine it is made of 1-in.-thick cardboard, which means fewer balls will escape. This is permeability—the relationship between permeance (number of holes) and the material’s thickness. A general rule of thumb: As the thickness doubles, the permeability is cut in half. So, a 2-in.-thick cardboard box would allow half as many balls to make it all the way out of the holes, as compared to a 1-in.-thick cardboard box. This proportion isn’t 100% accurate, but it will take someone with the letters PhD after their name to explain why. (I’m looking at you, Allison Bailes.)

Yet another test method

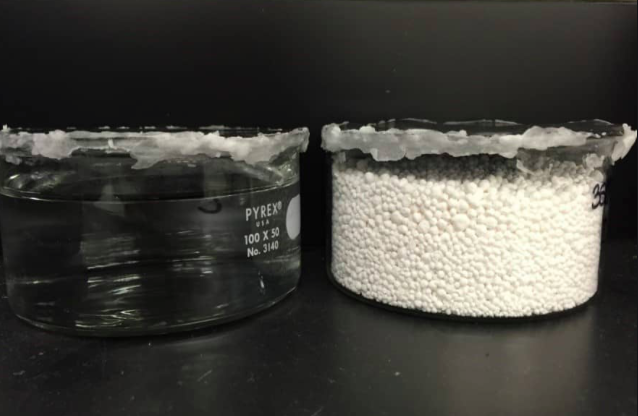

Now, let’s look at how we test the permeance of a material using the ASTM E96 “standard test method for water vapor transmission of materials,” which is commonly known as a wet cup/dry cup test. This method reveals some interesting characteristics about how materials behave.

Here are the basics: Two cups or dishes are prepared; one is full of water (the wet cup), the other is full of a desiccant (the dry cup). A sample of whatever is being tested is placed across the top of each cup and sealed tightly with tape, wax, etc. The two cups are weighed and then placed in a test chamber, which is held at a constant humidity level and a constant temperature. Periodically, the two cups are taken out and weighed. What’s happening here is that we’re inducing a vapor pressure differential across the material to see how it behaves. The inside of the wet cup is near 100% relative humidity (a higher vapor pressure than the chamber), and the inside of the dry cup is near 0% (a lower vapor pressure than the chamber). Physics being physics, the wet cup will lose water vapor and the dry cup will gain water vapor. The periodic weighings monitor the rate at which that happens and that is what defines the permeance.

Material valves

So, why do we have a wet cup and a dry cup—wouldn’t either one tell us the rate that moisture moves across a material? It’s time for that ubiquitous building science response: “It depends.” Some materials have a set relationship to how vapor passes through them. Like pouring water through a piece of window screen, it doesn’t matter which side of the screen the water is poured through; it flows at a rate set by the geometry of the material. Not all materials behave like this though. A common phenomenon with some building materials is that they become more permeable when wet—proven by the higher rate of vapor transport across the wet-cup sample. This phenomenon provides handy information, as it means that an assembly will transport vapor faster the wetter it gets. Materials that move vapor rapidly are considered open. Those that move vapor slowly are considered closed. These are our classes of vapor retarders.

The weakest link in the chain

Something to bear in mind when thinking about this stuff as it relates to building assemblies is that the permeability of an assembly is only as open as the most closed component in the system. For example, take a piece of CDX plywood (about 20 perms when wet), and put a piece of Ice and Water Shield membrane on it (1 perm or less)—that assembly is now only as permeable as the lowest perm component.

Don’t do stupid stuff

By now I’ve either bored you to tears or I’ve thoroughly confused you, so let’s get down to simple takeaways.

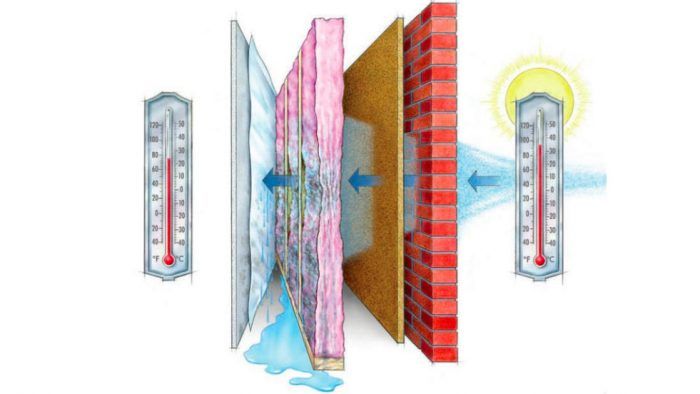

1. Don’t put closed materials on two sides of an assembly. Vapor is going to get in whether you like it or not, and there better be a way for it to get out.

2. Avoid putting the closed layer on the cold side of an assembly. This is inviting issues with excess moisture and potential condensation. If you’re not sure which is the cold side—or it changes periodically—go with a vapor-open assembly.

3. If you think the success of your assembly depends on the vapor performance of its components, you should probably go back to the drawing board. Any system that evokes concerns over vapor at the time of construction is likely to have major issues as time goes on.

4. It’s easy to treat some of these vapor issues as hard-and-fast rules but they aren’t. There is so much at play in a building that can influence the way moisture behaves that it would be impossible to say exactly what is going to happen. (You could change the entire performance of a wall system by simply cutting down or planting trees near it.)

5. This is confusing stuff for us humans, and big companies—even the most respectable among them—are run by humans. Be skeptical of data you see published regarding vapor performance. There are enough misunderstandings around the subject that bad information slips through the cracks. If it is a serious concern, verify data through multiple sources.

This really is a painfully simplified synopsis of the subject but that’s my goal here. There is a seemingly bottomless pit of questions to ask around this topic. I’m just starting the conversation….

_________________________________________________________________________

Originally published on GreenBuildingAdvisor.com.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Disposable Suit

Staple Gun

Loctite Foamboard Adhesive

View Comments

then why do so many builders use ZiP sheathing which when taped properly , is virtually impermeable ?//

Zip system seems awesome, like to good to be true! Surely someone has had a problem with it? Or is it just the miracle we have all been waiting for.