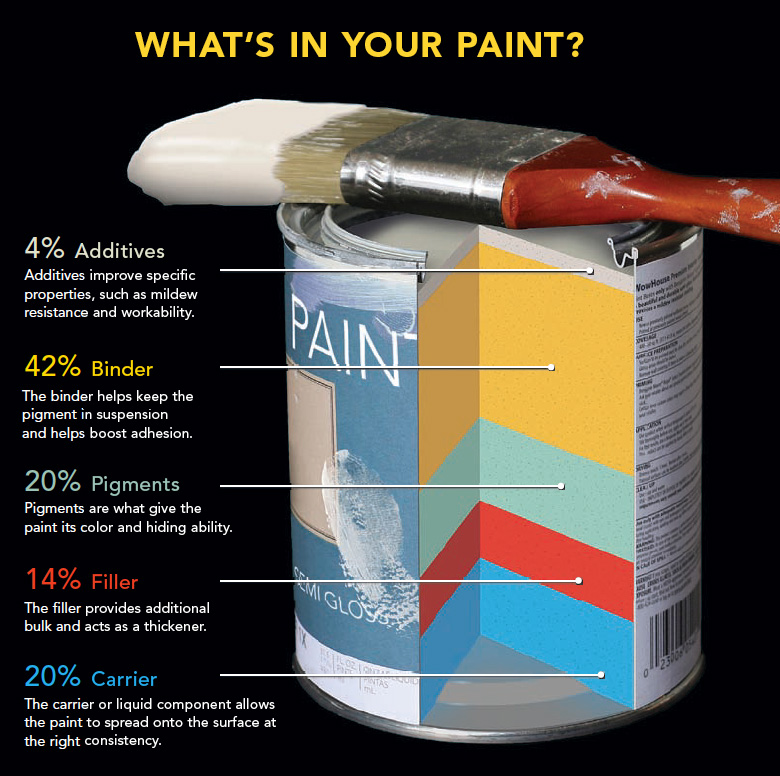

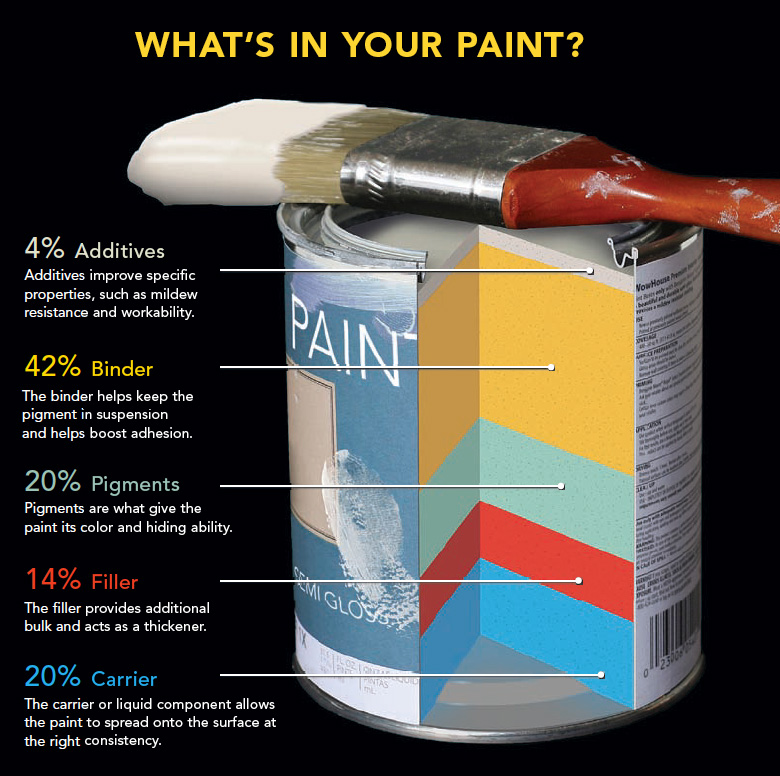

Although you’ve probably never thought about it, paint manufacturers don’t actually make the ingredients that they use in their paints. Instead, they buy the components from chemical companies and combine them to their own specifications. To ensure that the paint companies are getting the best-performing ingredients, the chemical companies employ paint chemists to formulate and test paint in many ways, including real-world scenarios.

I recently had the chance to meet with employees from the Dow Chemical Company and a team of technical experts who test paint for the Paint Quality Institute (PQI) in a complex near Philadelphia. This “paint farm” has more than 40,000 samples and includes painted building materials ranging from vinyl and fiber-cement siding to steel bridge parts and weathered decking. The complex even includes special racking to hold some of the samples upside down to simulate how paints perform under porch ceilings and soffits, where they won’t be washed by rain.

Because substrates and field conditions can be all over the map, the testers even apply paint samples to weathered primers and sunburned wood to simulate houses that have taken too long to get primed and top coated.

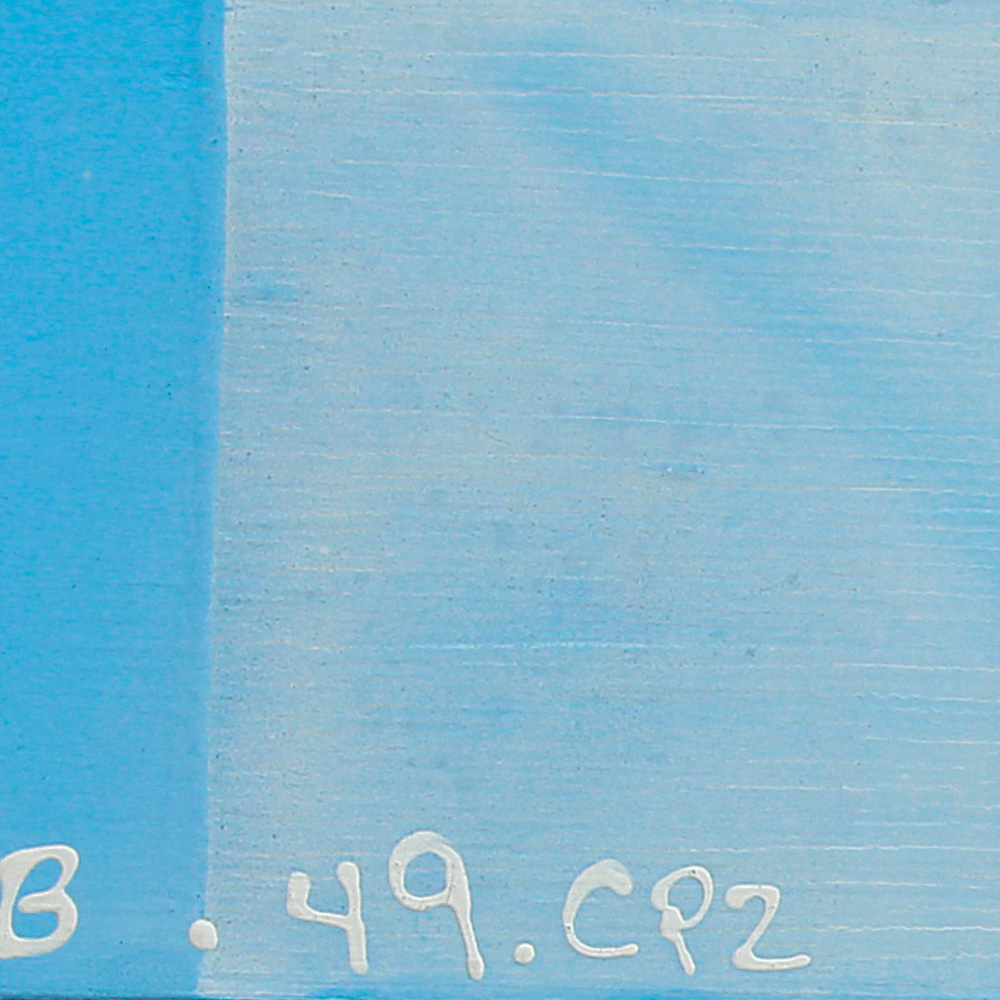

Every few months, the samples are photographed with automated equipment and the photos are checked for changes in appearance. The samples themselves also receive regular visual checks for adhesion, fading, cracks, chalkiness, mildew, and dirt.

The insights gained from decades of testing (the oldest samples date to the early 1960s) have improved both performance and workability. The company’s research also provides excellent guidance on how to solve most common paint problems, which are outlined.

What Matters Most?

Inorganic trumps organic- Pigments can be broken down into two basic types: organic and inorganic. Organic pigments—which include bright blues, yellows, and reds—fade faster and don’t cover as well as paints made with inorganic pigments. Inorganic pigments—which are usually mined minerals—make blacks, whites, barn reds, yellow ochers, and dark greens.

You get what you pay for- Additives are the most expensive components in a can of paint and have the biggest effect on its workability. Rheology modifiers help paint to go on properly and to resist spattering. Dispersants keep the pigments spread out so that they hide well. Biocides keep bacteria from forming in the can, and mildewcides prevent mold from growing on the paint film. Defoamers break down bubbles caused by shaking, stirring, and rolling. Cosolvents improve workability and allow painting at lower temperatures.

The more solids, the better- Solids are what’s left behind when the liquid carrier evaporates. They give a paint its hiding ability and contribute to its overall durability. Quality exterior house paint has a solids content from 35% to about 45% by volume. Paints on the higher end of the scale cover better and last longer. You can find the exact percentage by checking the product data sheet on the manufacturer’s website.

Paint Failures and Their Fixes

If a budget is tight, it’s better to cut costs on interior paint than exterior paint. Rain, sun, and pollution all take their toll on outdoor paint jobs. Shady locations, especially those shielded from rain by porch roofs or overhangs, are also susceptible to mold and algae. All of these challenges play out at the Paint Quality Institute’s outdoor test facility.

|

|

Alligatoring

Problem: Patterned cracking that resembles the skin of an alligator

Likely causes: Applying a hard rigid coating such as alkyd enamel over a more flexible coating such as latex primer; applying a topcoat before the undercoat is dry; loss of elasticity, which is part of the natural aging of oil-based paint

Solution: Completely remove alligatored paint by scraping or sanding, and then prime the surface with a high-quality oil-based or latex primer. Topcoat with an acrylic-latex paint. |

Blistering

Problem: Localized loss of adhesion resulting in bubbles in the paint film

Likely causes: Applying oil-based or alkyd paint over a damp or wet surface; moisture intrusion; exposing latex paint to moisture shortly after the paint has dried

Solution: If the blisters go all the way to the substrate, remove the source of moisture and scrape away the blisters. Prime and repaint with acrylic latex. If the blisters don’t go all the way to the substrate, scrape or sand them away and repaint without priming. |

|

|

Chalking

Problem: A fine powder on the paint film that causes color fading and results from weathering

Likely causes: Using a low-quality, highly pigmented paint; using interior paint in an outdoor application

Solution: Using a stiff brush or a wire brush, remove as much of the chalk as possible, then rinse with a garden hose or a pressure washer on a light setting. Check for remaining chalk by running your hand over the surface. If chalk is still present, coat the surface with a high-quality oil-based or latex primer, and topcoat with a high-quality acrylic latex. If little or no chalk remains and the paint is sound, priming may be unnecessary. |

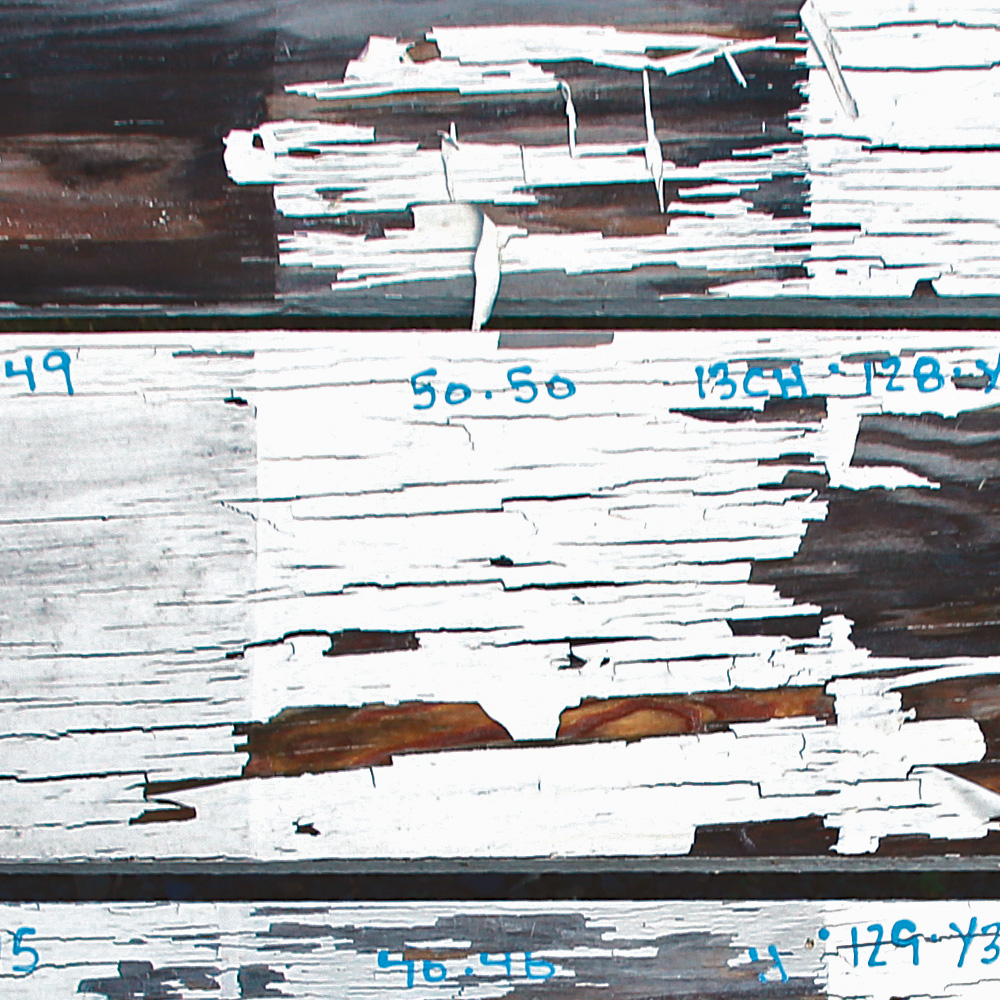

Cracking/Flaking

Problem: The splitting of a paint film from aging, which starts as hairline cracks and progresses to flaking

Likely causes: Poor-quality paint with inadequate adhesion and flexibility; overthinning or overspreading; poor surface prep or failing to prime; hardening and brittleness of aged alkyd paint

Solution: Remove loose paint by scraping, wire brushing, or sanding. Feather any hard edges, and prime bare areas before repainting. Use a high-quality paint and primer to prevent recurrence. |

|

|

Efflorescence

Problem: A white saltlike substance that leaches from mortar or masonry as water moves through it

Likely causes: Failing to remove previous efflorescence before repainting; moisture intrusion from interior or exterior sources

Solution: Eliminate sources of moisture, then remove the efflorescence and any loose material with a wire brush. After rinsing the surface, let it dry completely. Cover any bare areas with a high-quality primer before topcoating with a high-quality house paint or specialty masonry coating. |

Frosting

Problem: A white saltlike substance on the paint surface that can show up on any color paint but is less noticeable with white and light colors. It forms mostly under protected overhangs and porch ceilings that don’t get washed by rain. On masonry, it is sometimes mistaken for efflorescence.

Likely causes: Using dark-colored paint with a calciumcarbonate filler (a common industrial mineral); using dark-colored paint over a primer with a calcium-carbonate filler

Solution: Often a stubborn problem, frosting is best removed by sanding (wood) or wire brushing (masonry). After a thorough rinse, let the surface dry, and then prime with an alkyd-based primer. Topcoat with a high-quality exterior paint. |

|

|

Mildew

Problem: Black, gray, or brown areas of fungus growth on the paint surface or on nearby caulked areas that form most often in damp places with little or no direct sun, such as north-facing substrates

Likely causes: Using a low-quality paint with an inadequate mildewcide; failing to prime bare wood before painting; repainting a substrate where existing mildew wasn’t removed; too thin of a paint film

Solution: You can test for mildew with a few drops of household bleach, followed by rinsing (shown above). If the discoloration bleaches away, it’s most likely mildew. Remove the rest with a solution of one part bleach to three parts water. Pressure washing also works. Rinse thoroughly, prime bare areas, and then topcoat with a high-quality exterior paint. Such paints typically have more mildewcide than cheaper products. |

Peeling

Problem: One or more layers of paint/primer falling off due to poor adhesion

Likely causes: Seeping moisture from leaks or failed caulk joints; moisture escaping through exterior walls, especially when the paint is oil-based; poor surface preparation; applying oil-based paint to a wet surface

Solution: Eliminate sources of moisture. Prepare the surface by removing all loose paint with a scraper or wire brush, and prime any bare spots. Repaint with acrylic-latex paint, which offers better adhesion and water resistance. |

|

|

Poor Hiding

Problem: The failure of exterior or interior paint to sufficiently cover the underlying paint or surface to which it’s applied

Likely causes: Paints mixed with neutral or deep bases, which don’t have as much titanium dioxide as paints mixed from light and medium bases and so don’t cover as well; using a paint that’s much lighter than the underlying surface, or using a paint with low-hiding organic pigments; application of a thinner coat than what’s recommended

Solution: Start with a high-quality paint, which covers better than a lower-quality paint. If the surface is significantly darker than the new paint, it should be covered first with a tinted primer. Apply the paint at the manufacturer-specified spread rate, using the recommended spray tip or roller. |

Tannin Staining

Problem: Brown or tan discoloration caused by tannins within common wood species such as redwood, cedar, and mahogany

Likely causes: Skipping primer; using a primer with insufficient stain-blocking qualities

Solution: Correct any sources of excess moisture. After thoroughly cleaning the surface, apply a high-quality, oil-based, stain-blocking primer. In some cases, a second coat of stain-blocking primer may be necessary to hide the staining. Topcoat with a high-quality acrylic-latex paint. |

Click the View PDF button below to see this article as a PDF.