How to Install a Toilet

The essential step-by-step guide to removing your old toilet and installing a new one.

Unless you’re dealing with new construction, the first step will be to remove the old toilet.

To start, place a bucket or tray under the water supply valve to catch any drips. Then shut off the water supply to the tank by turning the handle clockwise. Add a dash of bleach to help disinfect the tank and bowl as you flush the toilet the last time. Hold the handle down until the tank is empty and use a sponge to soak up any remaining water.

Now disconnect the water supply line using a pair of slip-joint pliers to break the connection, then finish unscrewing the hose by hand. To make removal easier, separate the tank from the base. Use a large flat-head screwdriver to keep the through bolts from spinning as you reach under the tank to remove the nuts using a deep socket wrench. To remove the tank grab it securely and lift pouring any remaining drops of water into a bucket before carrying it out of the room.

Now empty the bowl. Even though there’s bleach in the water it’s still good practice to wear disposable gloves. To remove the base use a putty knife to pop off the caps that cover the flange bolts and an adjustable wrench to loosen and unscrew the nuts. If the toilet was caulked or grouted in place break the connection using the same putty knife. To lift the toilet, hold the rim just behind the bowl with one hand and grab the underside of the base with the other as you lift it up and off the bolts, setting it on a scrap of cardboard so you can scrape the excess wax from around the outlet. Stuff a rag into the outlet to prevent any dripping as a bowl is carried through the house also insert a rag into the closet flange to prevent sewer gases from filling the room while you scrape residue from the floor and any remaining wax from the flange in preparation for the new toilet.

For standard sized toilets closet flanges are centered 12 inches from the back wall and are seated on top of the finished floor to minimize the gap between the closet flange and the outlet on the underside of the toilet. For installation, first dry-fit the base to check the fit. If there’s any wobble due to uneven tiles or minor inconsistencies and the flatness of the porcelain bowl use red rubber gasket material to remove the wobble. This product can be found at local home centers.

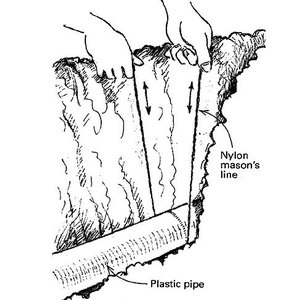

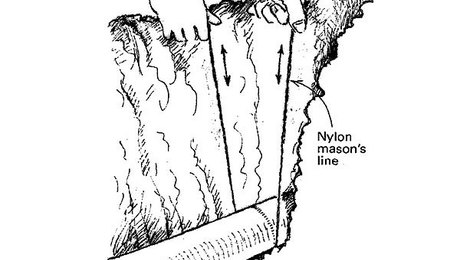

Once the shim is in place draw a reference line to help guide the toilet for repositioning. Next set the flange bolts that come supplied with a toilet into the slot on each side of the closet flange and use a tape measure to position them 12 inches from the wall on both sides. Pencil in lines to mark the location for each bolt making it easier to visually line the toilet when it’s installed. Remove the rag and tighten down the collars to the flange bolts stand straight on their own. Then place the wax ring centering it in the closet flange.

To install the new bowl lift it in place and hover over the flange as you align the bolts holes on both sides and then slowly drop it into place. The bowl will ride a little high until the wax is compressed. Use your body weight to compress the wax ring until the porcelain bowl make solid contact with the floor. Next thread the supplied nuts onto each flange bolt tightening them alternately so that the toilet rests evenly and never more than hand tight or you’ll risk cracking and porcelain. Finally, trim the rubber shim flush with the bowl.

Before installing the tank check that all the factory nuts are tight and all the gaskets are in place and secure. The tank simply drops into place behind the bowl and is secured with nuts that are hand tightened with a disposable plastic wrench that comes with the new toilet. To ensure the gaskets seat properly it’s important to work back and forth between bolts, tightening each a little at a time until the tank is snug.

With the bowl and tank both installed the supply line can be reconnected. Remember not to go beyond hand tight. Now turn the supply valve on and fill the tank. When it’s full adjust the height of the float valve until the water level is about three-quarters of an inch below the top edge of the fill tube. Give the toilet a test flush and check for leaks where it meets the floor.

If everything looks good, install the seat with the supplied hardware. Some flange bolts need to be cut with a hacksaw before installing the bolt caps, but this manufacturer eliminated that step allowing the bolt caps to fit over the full length bolts. The last step is to apply a bead of adhesive caulk around the joint where the toilet meets the floor—eliminating the chance of water wicking in around the base. Finally, position the lid on the tank and the toilet installation is complete.

View Comments

Wow - pretty detailed for this crowd.

Well first I use a five gallon bucket about 1/2 full to help remove the remaining water in the bowl. How ? By dumping it in rapidly causing a rapid removal of all but a little water in the bowl.

I also use a construction plastic bag to set the toilet in. I roll the edges down, set toilet in the bag, raise the edges and remove. No water spill unless your bag has a hole, so use a new bag.

In some cases I have switched to the new neoprene doughnuts. Does not always work due to flooring, but I like them better than wax. That was a fancy two hole tank.

There is now a material that gels the remaining water in the trap so that it doesn’t spill when removing and carrying the toilet. I have some but haven’t tried it yet.

I was always taught not to caulk around the bottom of the toilet where it meets the floor. The reason was that this way if there is a leak at the donut for some reason you’ll hopefully see it coming from under the toilet before it works its way to the subfloor and rots it out. I imagine the trade off is dirty water and germs getting under the toilet.

I’m curious to know if anyone else has any thoughts about this.

MY TOILET PET PEEVE

The projects and techniques published in FHB and GBA are arguably high end or at least better than average. Why is it that most of featured toilet installations use flexible plastic supply lines to the fill valve? I am a (serious) DIYer. Long ago I purchased basic bending tools and learned how to cut and bend the chromed copper supply lines. It doesn’t take but a few minutes and the appearance is far superior to plastic tubing.

I have been annoyed when commercial plumbers have serviced toilets at my rental property, reset the toilet and replaced the perfectly good copper tubing with plastic. Sometimes they don’t even bother to remove the paper label from the plastic tubing.

Jeez!