How to Rough in a Toilet Flange

Master plumber Rex Cauldwell explains how to lay out, cut the hole for, and fasten a toilet flange to the subfloor.

Roughing in a toilet flange involves measuring for its location from the finished wall, cutting the hole for the toilet flange, and fastening the flange to the floor. The standard location of the center of the flange is a minimum of 12 in. from any finished wall. In addition, the bottom of the flange should be level with the finished floor. If you plan to lay tile, the flange needs to be attached to the subfloor before the tile goes in, but be sure to shim the flange up by the combined thickness of the tile and mortar.

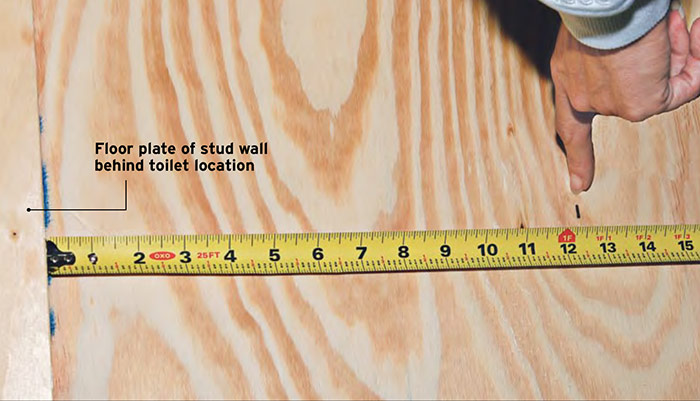

To start, locate the centerline of the flange, then measure and mark a point 12 in. from the bottom plate, plus the thickness of any finished wall you haven’t installed yet. This measurement will typically total 12 1⁄2 in. (assuming 1⁄2-in. drywall). That mark represents the center of the hole for the flange pipe that goes through the floor.

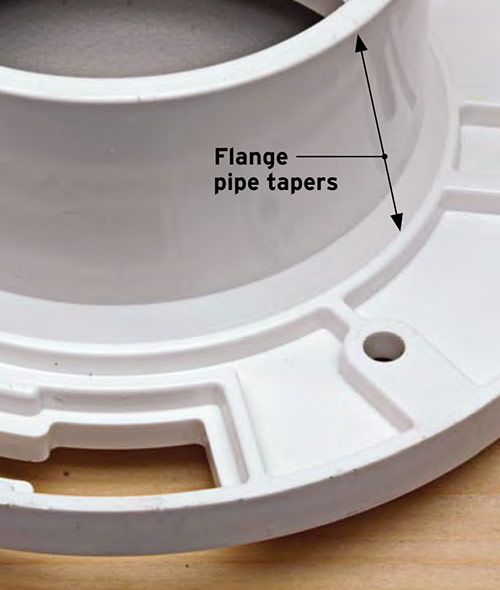

If the hole’s too small, the pipe won’t fit. If it’s too large, you won’t have any wood to hold the screws 1. A CD is close to the proper diameter and makes an easy template. In fact, if you’re using a 3-in. pipe flange (the most common), and the flange pipe bevels, the outside diameter where it meets the floor is about 4 3⁄4 in.—the diameter of a CD 2. For flanges without a bevel, use the CD to make a reference circle, then center your flange inside that circle to mark the pipe diameter 3.

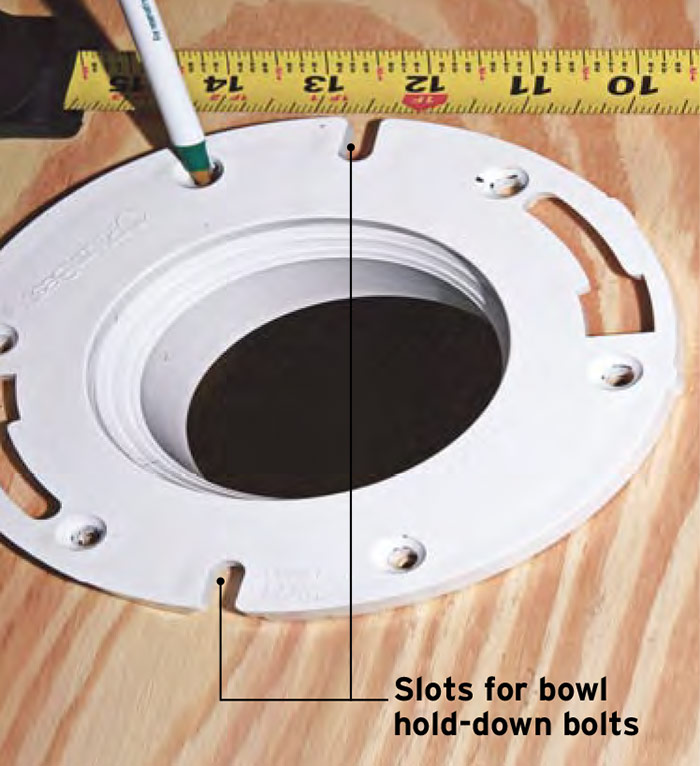

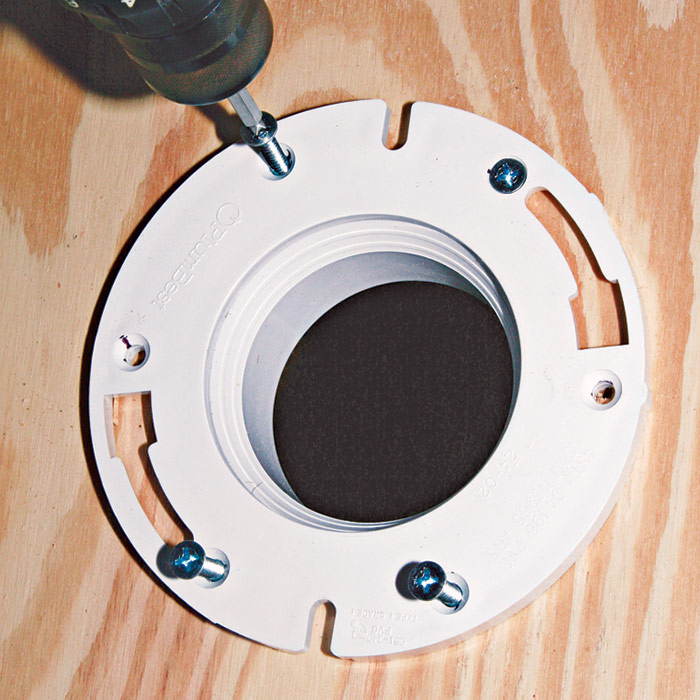

Drill a 3⁄8-in. hole with a twist drill so its edge falls just on the inside edge of the circle, then insert a rough-cut jigsaw blade and carefully cut the circle out, turning the saw constantly to keep the blade on the line 4. Insert the flange to verify the proper hole diameter. Orient the flange so the horseshoe-shaped cutouts on each side are at dead center—each 12 1⁄2 in. from the wall behind the toilet. Holding the flange in place, mark the location of the flange screws 5. Don’t use the arced cutouts on the flange; they can allow the bowl hold-down bolts to spin when you try to remove them at some later date. Remove the flange and, using a drill bit about half the diameter of a #12 by 1 1⁄2-inch flat-head wood screw, predrill the holes at your marks

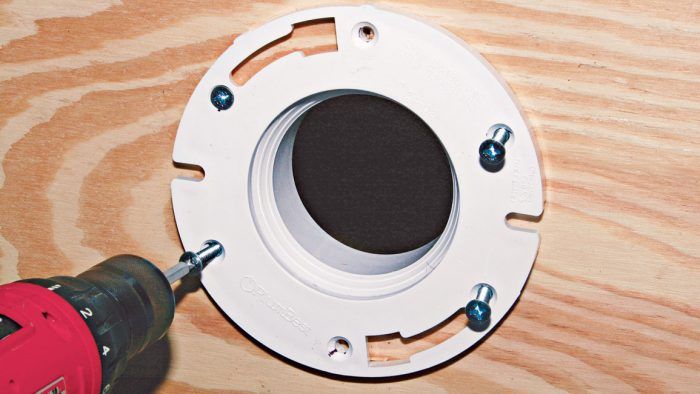

6. Predrilling makes driving the screws easier and keeps the wood from splitting. Line up the flange so the mounting holes match with the bowl hold-down slots parallel to the back wall, and drive in the screws with a cordless drill 7. Install any remaining fixtures and the finished wall and floor. Rather than sliding the bowl hold-down bolts into their slots and having them fall over as you try and drop the bowl on the flange, keep them vertical with a washer and nut 8. Then mount the toilet.

Excerpted from Taunton’s Plumbing Complete by Rex Cauldwell.

Excerpted from Taunton’s Plumbing Complete by Rex Cauldwell.

Available at Amazon.com.