Trouble-Free Toilets

The floor, flange, and sealant can mean the difference between success and failure.

Synopsis: Whether you have a leak or just want an upgrade, removing and installing a toilet is an approachable project that requires only the most basic tools. But the success of the installation goes beyond what you can see on the surface. A long-lasting toilet installation requires a strong, stable floor frame, a properly positioned closet flange, and a bead of sealant where the fixture meets the floor.

I’ve installed, removed, and replaced more toilets than I care to count. In some cases, a toilet has to be replaced because the necessary repairs to the inner workings of the tank aren’t worth the effort when compared to the cost of upgrading to a new fixture. There’s not much I can do to predict how long these internal components of a toilet will hold up, but I certainly can ensure that the plumber or homeowner who pulls the toilet isn’t faced with additional repairs to the bathroom. I’ve pulled lots of toilets that have been in service for 50 years or more yet had no evidence of wax-ring failure, leakage, or rot. The difference isn’t in the quality of the toilet but in the quality of the installation.

In my experience, the three essential aspects of a long-lasting and trouble-free toilet installation are a stable floor frame, a closet flange that’s installed at the right height, and a bead of sealant or grout around the base of the toilet where it meets the floor.

The floor frame must be stable

From a framing perspective, there isn’t anything special about the floor under a bathroom. If things go wrong, it’s usually because somebody has reduced the strength of the floor by notching or drilling where they shouldn’t, or because water damage has led to decay. Either of these problems will lead to movement in the floor, and that will affect the seal between the toilet and the closet flange.

Assess the condition of the floor by looking for loose tiles or feeling for sponginess. If there’s access, always go below and lookup for notched or drilled joists or for softness in the wood, which indicates rot. If the subflooring around the flange is rotten, it’s best to cut out the old closet flange — either from below using a reciprocating saw, or from above with a specialty tool such as the Flange-off (keco.com) or the Ram Bit (pascospecialty.com) — and replace it along with the section of flooring.

If you have to drill holes in the floor joists to route the waste line, do so through their center, and be mindful of the structural restrictions. Although not permitted by a strict interpretation of the building code, drilling waste-line holes through 2×8 and 2×10 joists is often approved by building inspectors if you agree to reinforce the joists. Reinforcement options include doubled joists, plywood gussets, angle iron, headers for transferring the load, and a support wall.

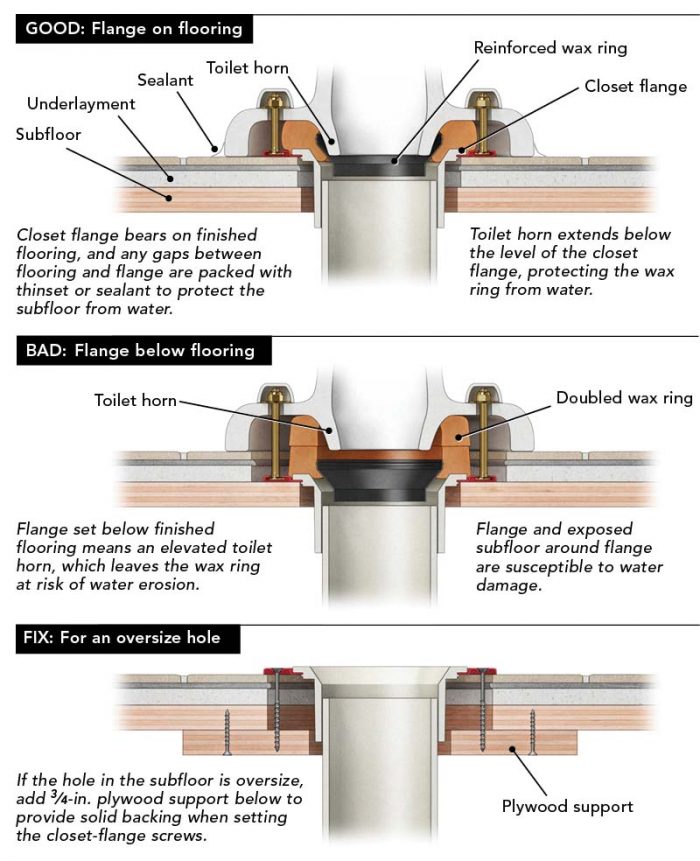

Flange over the flooring

The underside of the closet flange should sit level and bear evenly on top of the finished floor. If new flooring has been added on top of the existing flooring, use spacer rings to extend the flange up. Although common, it’s never OK to stack up wax rings to span the gap between a recessed closet flange and the horn of the toilet. A correctly installed wax ring is there to prevent sewer gas from entering the bathroom, not as a waterproof seal.

Don’t skip the Sealant

Some plumbers argue that applying sealant where the toilet meets the floor will trap water and lead to rot if the wax ring ever fails. But sealant in this area is required by code, and for good reasons. The sealant prevents condensation on the outside of the bowl from wicking between the toilet and the floor, where it won’t easily dry out. More importantly, it seals against soiled water following the same path if the toilet ever overflows. I always flush a newly installed toilet multiple times before sealing it to the floor with Phenoseal adhesive caulk.

From Fine Homebuilding #254

To view the entire article, please click the View PDF button below.