Low-Risk Reroof

Roofing contractor Stephen Hazlett shares his reliable methods for protecting a house and managing job-site workflow to execute a high-quality roof replacement job.

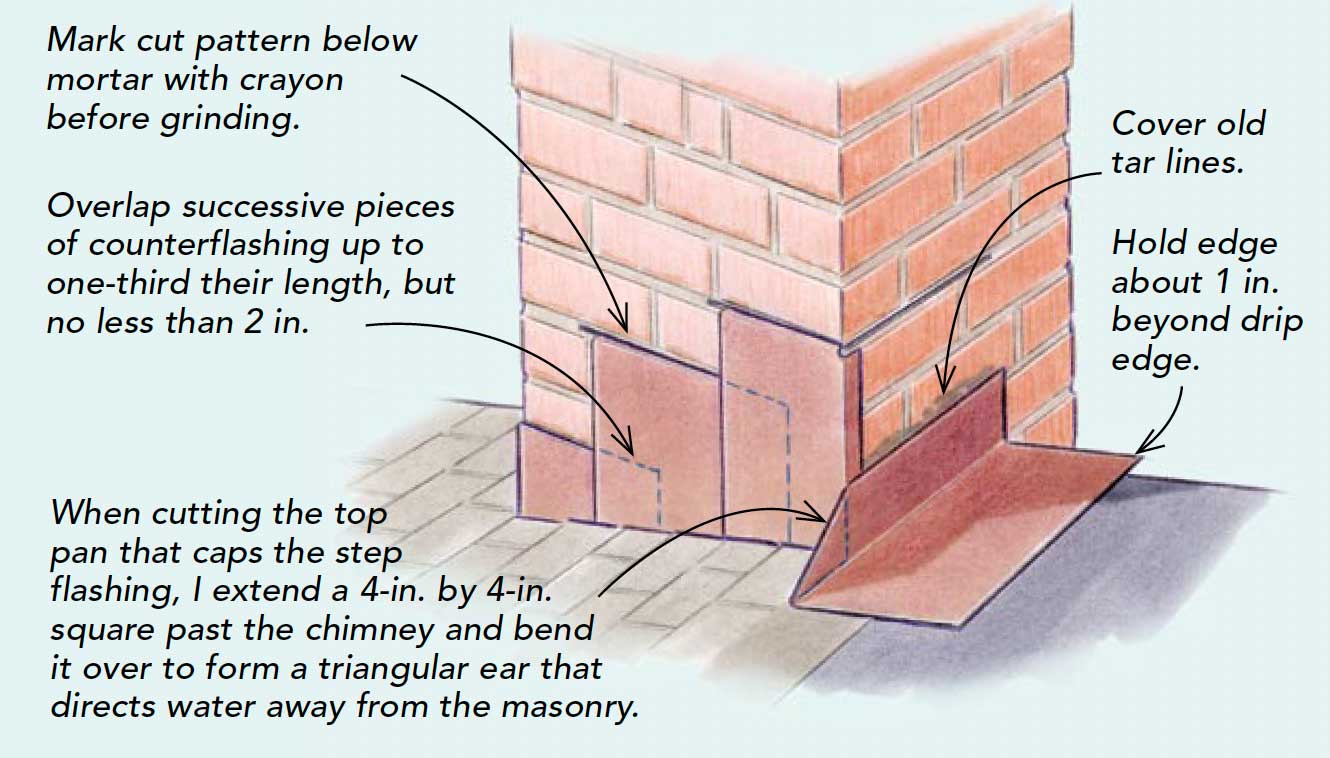

Synopsis: Replacing the roof on an occupied home can be a scary prospect. Exposing the roof sheathing to the elements is risky, especially if all the shingles are off the roof and a summer storm brews up suddenly. Roofing contractor Stephen Hazlett has a better way to manage reroofing jobs. By tearing off only what can be reroofed in a day, Hazlett doesn’t have to rely on the thin promise of a tarp to keep a home safe overnight in the event of inclement weather. Hazlett’s methodical system involves checking weather reports and managing the workflow with an efficient crew. This article includes a sidebar about the proper way to repair and replace chimney flashing.

On second thought, maybe there is a secret to this type of work: Don’t tear off more than you can reroof quickly, and keep a big tarp handy.

The most important tool is information

When planning a roof replacement, a lot of information should be gathered in advance: roof pitch, type of decking, number of existing layers of roofing, the history of roof leaks, and the way leaks were resolved.

Writing the proposal is the next step in planning the workflow. I break down the project into a logical progression: what my crew and I can accomplish each day. In doing this, I take into account ladder and scaffolding placements, access for dump and delivery trucks, and electrical-outlet locations. The most-important things I look for are where the old roof debris is going to land and how I can avoid damaging the siding, the landscaping, the awnings, and the lawn.

When I measure roof area, I confirm the thickness of the roof decking so that I’ll have patch stock on hand. In my area, many of the homes built in the ’20s were sheathed in #2 southern yellow pine. This 3/4-in.-thick decking tends to hold up better than the 38-in. or 1/2-in. plywood sheathing used in houses built in the ’60s, ’70s, and ’80s.

Some roofing contractors prefer to have materials delivered to the rooftop after the old roofing has been torn off, but I have materials delivered at least a day before work starts. We enjoy the peace of mind that comes from knowing we have everything we need on site before the first shingle is torn off.

Because every project we do involves an occupied home, weather always is a concern. The morning a reroof is scheduled to begin, I start tracking the weather at 5:30 a.m. I make a “go” or a “no-go” decision by 7 a.m., based on the size and complexity of the roof, the size of the crew, and the rain’s estimated time of arrival.

If the job is a go, I notify the crew between 7 a.m. and 7:15 a.m., and we are on site by 8. If I decide the project is a no-go, I notify the homeowner that the project has been postponed.

Protect the house with plywood and tarps

Once we arrive on site, we are in constant motion. Everything has been planned, so there is no need to waste time. The first things off the truck each morning are usually an assortment of large ground tarps. The ground tarps are spread out beneath the work area. Anything thrown off the roof lands on them. We have an assortment of sizes from 30 ft. by 40 ft. to narrow runners that fit between garages and fences, and in other tight spots.

Delicate shrubs and flowers often are covered with sawhorses, empty trash barrels, or sheets of oriented strand board (OSB), along with more tarps. Some houses need no more protection than ground tarps and shrub shields, but a couple of additional steps might be useful. We often use bungee cords to hang a large tarp along the lower edge of a roof and down to the ground. This allows the gutters to catch nails and small debris, and the tarp often can be used as a chute to direct larger roof debris to a specific location. We sometimes install roof jacks and planks along the lower roof edge to catch debris and to protect awnings or a swimming pool. This is also a good strategy when houses are extremely close to each other. In that case, all debris is tossed carefully to a specific safe landing area.

Tear off a little at a time

Our main tearoff tool is the Shing-Go shovel, which we call a shingle eater. We can remove 99% of the shingles from the roof with shingle eaters; for the rest, we use an assortment of pry bars, flat bars, and tin snips (for stubborn flashing). Shingle eaters can damage siding easily, so we stay about a foot away from sidewalls. I generally use my Estwing Roofer’s Bar to clear out the wall flashing and the adjacent shingles. This bar works better for me than the common flat bars that most roofers use.

We prefer to start from the ridge and work our way down the roof, each worker tearing off a swath (we call it a rack) about 5 ft. wide. A race always is going on to see who can tear off their rack first. A crew of three workers usually tears off an area about 15 ft. wide from the ridge to the gutter in one pass, then moves down the ridge and tears off the next 15-ft.-wide section.

The trick to using a shingle eater is to get it under shingles and not pull it back out. The teeth on the blade of the tool allow you to hook each roofing nail and pull it out with a levering action. I have found that it is less strenuous and more productive to sit on the roof and tear off shingles to my left or below me (I am right-handed). This position is safer because it keeps my center of gravity low. It also allows me to employ my body weight favorably in a rocking motion while pulling down on the handle and levering the shingles and nails off the decking. Inexperienced crew members who bend over and push the shingle eater with their arms and shoulders simply can’t keep up with my pace.

Plywood decking allows a much faster tearoff because there are far fewer board edges to catch the teeth of the shingle eater. I find that 1×8 decking is difficult to work with; sometimes I have to tear off sideways along the length of each deck board to avoid catching an edge every few inches. Tearing off along the length of each board also puts less torque on the decking and causes fewer split boards.

With experienced roofers, tear-off can go surprisingly quickly, often within an hour. If I am working solo, I might tear off the old roof until about 10 a.m. before I start reroofing. Remember, there is a finished, occupied home underneath the roof.

Clean, repair, and dry in the roof

Once the old roofing is torn off, we use a plastic lawn rake to clear off loose shingle pieces; then we sweep down the roof deck to remove the loose debris and shingle grit that can make footing hazardous. Next, we cut out rotten wood and replace it with new solid material. Anyone not needed to replace decking pulls out nails left by the shingle eaters. After the wood replacement is finished, we nail off the entire roof deck with 8d nails in a nail gun and then sweep off the roof deck one last time.

With a clean, solid, safe roof deck, the tearoff is complete, and we can begin the new-roof installation. We install drip edge around the perimeter of the roof. Then we install peel-and-stick membrane along the lower edge of the roof. We install at least one 3-ft.-high course along the bottom edge. If a single course doesn’t extend high enough up the roof to correspond with a point at least 12 in. inside the wall, then we might need to install a second course. Check local codes for this detail because unexpectedly doubling the peel-and-stick membrane on a large job can take several hundred dollars out of your pocket. I also put peel-and-stick membrane in valleys and around chimneys.

I use #30 builder’s felt to dry in any roof decking not covered with the peel-and-stick membrane. After the whole roof is dried in, we usually snap a chalkline, marking every other shingle course. If three-tab shingles are being used, we snap a couple of vertical lines to maintain a 6-in. shingle offset. We like to rack three-tab shingles straight up the roof on smaller or steep roofs and stairstep larger or easy-to-walk roof areas. No vertical chalklines are necessary for dimensional shingles, only a few horizontal course lines.

Lunchtime is anywhere from 10:30 a.m. to 1 p.m., depending on progress and the weather outlook. I like to have all chalklines snapped before lunch so that when we return, we can begin installing new shingles immediately. I frequently use lunchtime as a chance to grind out the mortar joints in the chimney for reflashing. Doing this work at lunch means that I won’t spew dust and grit on my coworkers.

Steep roofs can complicate your strategy

|

Stephen Hazlett owns Hazlett Roofing & Renovation in Akron, Ohio. Photos by Daniel S. Morrison, except where noted. Drawing: Dan Thornton Product photo: Krysta S. Doerfler.

Fine Homebuilding #188

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Fall Protection

Peel & Stick Underlayment

Flashing Boot Repair