Running Exterior Trim

Fascias, rakes, soffits, and corner boards aren't scrutinized like interior woodwork, but they still have to look good and stand up to weather.

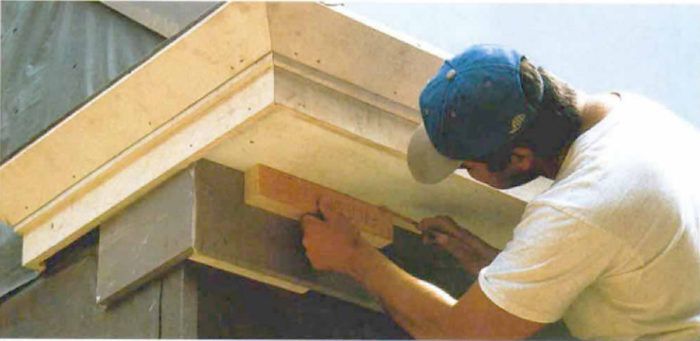

Synopsis: This guide to installing exterior trim emphasizes details that promote longevity, from selecting the right stock to using flashing to prevent water infiltration. The author, a New England builder, discusses eave and rake details, fascia and soffit assemblies, traditional cornice returns, corner boards, and water tables.

No part of building a house is more fun than putting up the exterior trim. It’s like decorating a cake or coloring in a picture. After the rush of framing lumber and plywood, the trim is the welcome stage of finer joinery that can bring out the house’s character.

In more than 17 years of building in New England, I’ve learned a few things about wood, weather and details that make trim last. Some lessons come from my own mistakes, but others come from working on old houses and seeing the legacy of carpenters whose work still looks good after more than a century. I like to imagine that the work my crew and I have done will be as praiseworthy a century from now.

Good trim begins with top-notch stock

The first step we take to help ensure that the trim work stays straight and true for years to come is choosing the right material. For exterior trim, we use eastern white pine, D-select or better, almost exclusively.

Western red cedar is also an excellent choice. Cedar is far more rot-resistant than pine, and because it’s typically quartersawn or vertical grain, there is little chance of cupping and warping. However, cedar is light and brittle, and tends to split more easily than pine. Perhaps the best argument for pine is that it’s less expensive, and it does not require the harvesting of old-growth trees.

For this house, we used 1-in. select pine (3/4-in. nominal thickness) for all the trim except the water tables, which required thicker stock. The water table was made of 2-in. #2 pine that we were fortunate enough to find at a local sawmill. It was far less expensive than the alternative, 8/4 sugar pine.

Prime exterior trim on all sides

Another step essential to exterior-trim longevity is sealing each piece front and back with primer or stain before it’s installed. Moisture can enter trim through any unsealed surface, and sealing all exposed wood surfaces not only helps to keep trim from warping and cupping but also keeps moisture from lifting off the finish.

With this project — as with all projects — we try to have the wood on site far enough in advance so that the primer can dry thoroughly before we need to use it, especially in colder weather. But before we prime, we try to make any rip cuts, rabbets or grooves, such as the groove for the soffit-to-fascia joint. Cutting primed wood — especially when oil-based primer is used — can be hard on saw-blades and edge tools. Last, we keep several yogurt containers on hand as primer buckets, and we judiciously prime all exposed wood after every cut…

For more photos, drawings, and details, click the View PDF button below: