What’s the Difference: Common Tile Backerboards

HardieBacker, Durock, and DensShield each has characteristics that affect where it can be installed and how tile is placed on it.

Backerboard panels provide a flat, firm base for the installation of tile. They are resistant to the effects of water exposure, including swelling, rot, and mold growth, and they can be used in fire-resistant assemblies. Each type of backerboard costs roughly the same and is available in similar dimensions at most lumberyards. However, each has characteristics that affect where it can be installed and how tile is placed on it.

HardieBacker

Composition: HardieBacker is made of cellulose fibers that are layered with cement slurry and cured through high-pressure autoclaving. The boards are also infused with additives to inhibit mold growth.

Cost: $10.50 for 1/2-in.-thick 3-ft. by 5-ft. sheet

Weight: 2.6 lb. per sq. ft. (1/2 in. thick)

Mortar: Modified latex thinset should be used on HardieBacker. This type of thinset is more expensive than non-modified products and also sets up faster—a benefit when working with large, heavy tile.

Installation: HardieBacker is best cut with carbon-tipped sawblades or specialty cutting shears and fastened to studs or joists with 11/2-in. corrosion-resistant screws or nails.

Notes: HardieBacker has a smooth surface that allows the panel to be finished with products other than tile, including wallpaper and paint. This makes the panels useful for finished basements or garages that would benefit from the panels’ moisture protection.

Durock

Composition: Durock panels have an aggregated portland-cement core and are wrapped with a polymer-coated, glass-fiber mesh.

Cost: $11 for 1/2-in.- thick 3-ft. by 5-ft. sheet

Weight: 3 lb. per sq. ft. (1/2 in. thick)

Mortar: Tile can be set with modified latex thinset or nonmodified dry-set mortar. The latter is a less-expensive option with a longer working time.

Installation: Durock is best cut with carbon-tipped sawblades or specialty cutting shears and fastened to studs or joists with 11/2-in. corrosionresistant screws or nails.

Notes: Unlike other backerboard, Durock meets industry standards for resistance to freeze/thaw cycles, allowing it to be used in exterior applications.

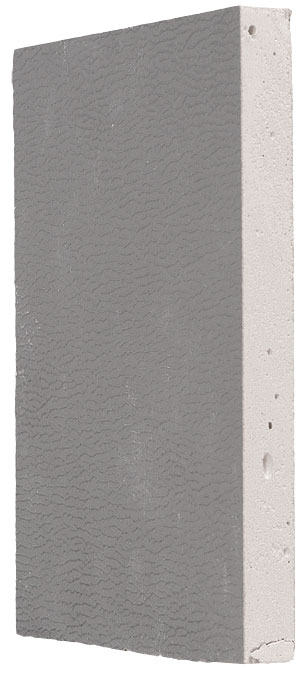

DensShield

Composition: DensShield is a blend of glass fibers and gypsum sandwiched between two fiberglass mats. The front of the panel is faced with an acrylic coating that acts as a moisture barrier.

Cost: $11 for 1/2-in.-thick 4-ft. by 5-ft. sheet

Weight: 2 lb. per sq. ft. (1/2 in. thick)

Mortar: As with HardieBacker, modified latex thinset should be used to set tile on DensShield panels.

Installation: DensShield can be cut with the same tools suggested for HardieBacker and Durock, or it can be scored and snapped like regular drywall. DensShield can be fastened to studs and joists with 11/2-in. corrosion-resistant screws or nails.

Notes: Unlike other backerboard, DensShield can’t be used where extreme levels of heat and moisture are common, such as in saunas or steam rooms.

Photos by: Krysta S. Doerfler, except where noted

This article originally appeared in Fine Homebuilding Magazine titled “Tile Backerboard 101”.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Get Your House Right: Architectural Elements to Use & Avoid

The New Carbon Architecture: Building to Cool the Climate

Code Check 10th Edition: An Illustrated Guide to Building a Safe House