Airtight Window Installations

Seal all air leaks between the wall and the window frame for an airtight barrier.

Installing a window is tricky. The first challenge is to do a good job with the flashing and water-management details. But once the window is fastened to the wall, you’re still not done: Now you have to pay attention to air-sealing. Every window is part of your home’s air barrier. For the air barrier to be complete, seal all air leaks between the wall and the window frame.

Start with the small gaps

The most crucial gap to seal is the crack between the window frame and the rough opening. Before tackling that gap, however, remember to seal three other locations with caulk or peel-and-stick membrane.

The first location is under the sill pan. Whether you’ve used a length of clapboard to create a sloping sill or a manufactured sill pan, you’ll need to caulk it to the framing. If you are making a site-built sill pan out of peel-and-stick flashing, there’s no need for caulk at this location.

The second location is under the window flanges—either all four flanges, if you are following the instructions provided by most window manufacturers, or under only the side and top flanges, if you follow the recommendations of most building scientists. Sealing the bottom flange is probably a bad idea because it prevents water leaks from draining out.

The third location is behind the drywall at the perimeter of the rough opening. This is especially important if you are following the airtight-drywall approach.

Move on to the big gap

Most window-installation steps—installing flashing, lapping the housewrap, and attaching the window—are done from the exterior. Once the window has been installed, it’s time to move indoors to address air-sealing details. Experts differ on whether any housewrap projecting into the interior of the rough opening should be trimmed back. For those who care about airtightness, the consensus seems to be that any housewrap between the window frame and the rough opening can interfere with air-sealing, so it makes sense to trim it back with a utility knife. The best time to do this is before the window is installed.

Many materials—caulk, spray foam, gaskets, tape—work to seal the gap between a window and a rough opening. Just don’t use strips of fiberglass insulation; it doesn’t stop air movement. Regardless of the material you use, it’s important that your air-sealing work doesn’t prevent water from escaping. Keep caulk, spray foam, or gaskets near the interior side of the gap you are sealing.

If the gap is 1⁄4 in. wide or less, it can be filled with caulk, with or without backer rod. Larger gaps should not be caulked.

Most builders seal the gaps between a window frame and the rough opening with canned, one-component spray foam. Low-expansion foam is usually best, because other types of foam can exert enough pressure to bow window jambs inward and cause a window to bind. However, as long as you use a light touch and don’t install too much foam, almost any type of canned foam will work.

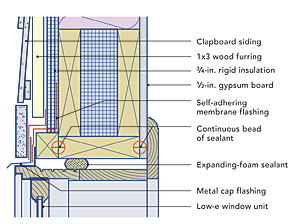

Window Head

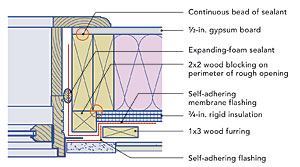

Window Jamb

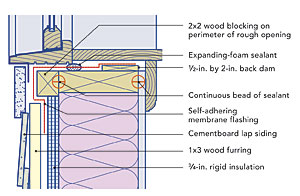

Windowsill

European air-sealing materials may be better than caulk or foam

European builders say that either EPDM (synthetic rubber) gaskets or special airsealing tapes do a better job of sealing cracks than caulk or spray foam because these products are more flexible, stay flexible longer, and create a better air seal.

Gaskets

The EPDM gaskets that European builders use to seal around windows resemble backer rod. One problem with gaskets is that shims interrupt the continuity of the gaskets. To address this problem, gaskets can be trimmed to fit between the shims, or the window can be installed with special European screws called shim screws instead of wooden shims.

A shim screw has a threaded outer sleeve holding a captured free-spinning lag screw. A special installation tool grabs both parts simultaneously so that the screw can be installed in a hole drilled in the window frame. The tool is then used to screw the lag into the rough framing while the sleeve remains fixed in the window frame. Then the lag screw can be adjusted to make the window plumb and level.

The best source for shim screws and EPDM gaskets is Conservation Technology (www.conservationtechnology.com). The company offers three sizes of gaskets that can be used to seal the gap between window frames and rough openings: BG44 for gaps 1⁄4 in. to 1⁄2 in., BG46 for gaps 3⁄8 in. to 3⁄4 in., and BG48 for gaps 1⁄2 in. to 1 in.

Don’t forget the drywall

Windows are an essential part of a home’s air barrier, so getting the installation details right is critical. It’s becoming common practice to use low-expanding canned spray foam to seal the shim space between the window jamb and the framing. It’s just as important to seal the drywall to the framing around the entire perimeter of the rough opening.

Tape

Many energyconscious European builders use air-sealing tapes to seal around windows. Siga Corvum 12/48 tape is one such product available in the United States; it can be ordered from www.smallplanetworkshop.com. This prefolded Siga tape has 1⁄2- and 2-in. legs. The narrow leg is stuck to the window, while the wider leg (which has a paper backing for easier placement) is stuck to the window’s rough opening. The maker claims the tape is stronger and more reliable than caulk.

Drawing and photos by Dan Thornton and Steve Baczek