Building Wooden Screen Doors

Durability and aesthetics hinge on sound joinery and steadfast materials.

Synopsis: Screen doors don’t have to be aluminum. The author, an architectural millwork specialist, explains his approach for building traditionally styled wood screen doors. Mortise-and-tenon joinery makes the door durable. Special screening tools and techniques make the process efficient.

According to Steven J. Phillips’ Old-House Dictionary, the purpose of a screen door is “to allow ventilation but exclude insects.” Of course if it can accomplish that gracefully, all the better. During the late 1900s, when screen doors first became popular in this country, most were designed to enrich, or at least complement, the architecture. To that end, a wealth of styles emerged, many of which were featured in pattern books and copied by carpenters. Even many of the mass-produced screen doors in those days were both fetching and functional.

Nowadays, though, the ubiquitous aluminum screen door is the one most likely to appear on someone’s doorstep. To be sure, aluminum doors have their place, but all too often they wind up in classical entryways or over finely wrought entry doors, spoiling the intended effect.

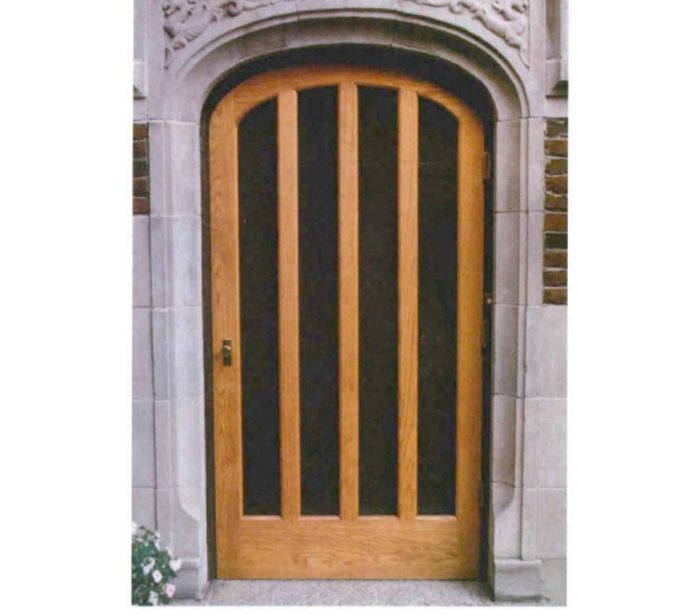

A wooden screen door, on the other hand, can be unobtrusive, allowing the main door to show through. Or it can mask the door behind it and serve as an architectural ornament in its own right. As a home builder and architectural woodworker, I’ve built screen doors both ways. And in either case, the basic construction principles are the same.

Screen-door anatomy

In its simplest form, a screen door consists of two stiles, a top rail and a bottom (or kick) rail. Traditionally, most screen doors were built of pine, oak, and other domestic woods. But pine is soft, and oak isn’t especially stable or weather resistant. Cypress is a good choice, but here in Maine it’s hard to find. Though I’ve used a variety of woods for my screen doors, I prefer Honduras mahogany. It’s strong, stable, and holds paint and varnish well.

I build my doors 1-1/8 in. thick, a compromise between light weight and sturdy construction. Originally, I joined stiles and rails with dowels because it was quick and easy. But after a while, the joints loosened. Screen doors bear the brunt of the weather and they get slammed a lot, especially when they’re spring-loaded. Pneumatic closers (the kind you see on most aluminum screen doors) are especially hard on wooden screen doors because they hesitate in mid-swing and cause excessive racking. Nowadays, I use mortise-and-tenon joinery exclusively for my screen doors.

Stiles and top rail are a minimum of 4 in.wide, which makes for a sturdy door and provides plenty of room for locksets and springs. The kick rail is at least 8 in. wide to keep the door from distorting. I cut two narrow tenons instead of one wide tenon in the kick rail so that the mortises don’t weaken the stile.

Tenons are 3 in. long and 3/8 in. thick, or one third the thickness of the stock. A 1/2-in.-wide by 3/8-in.-deep rabbet along the inside edge of the frame accommodates the screen and screen stop. That’s all there is to it.

For more photos, drawings, and details, click the View PDF button below: