Choosing Impact-Rated Glass

Understand the relative impact resistance of laminated glass.

Q:

We are planning to replace all of the original single-pane windows (1997 construction) in our home with windows that are more energy efficient and that will meet storm codes for South Florida. Although we’ve found a lot of valuable information online, we’ve yet to come across anything that explains the difference between 5⁄16-in.-thick glass and 7⁄16-in.-thick glass. Some of the window estimators we’ve met with are pushing the 7⁄16-in. option as better, while others are telling us that 5⁄16-in. glass will work just fine. Is there a difference?

Luis Rosario, None

A:

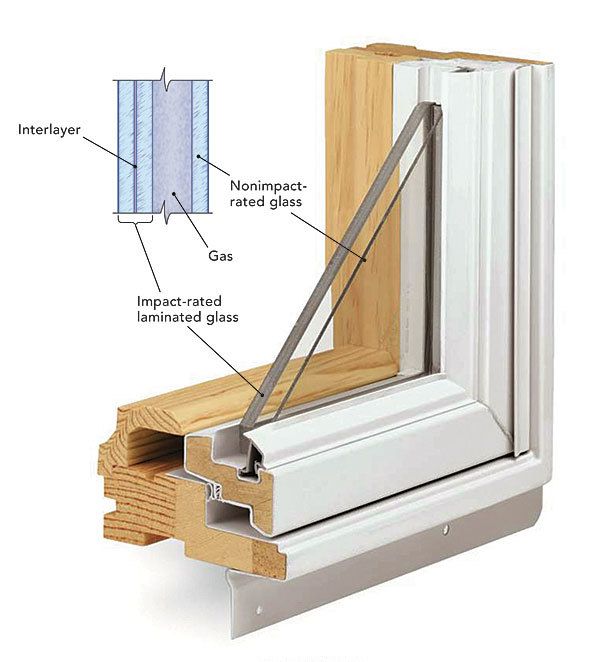

Greg Smith, a 20-year veteran of the glass industry, replies: Because you live in South Florida, I’m assuming that you are talking about impact-rated laminated glass in your windows rather than standard, nonimpact-rated glass. Impact-rated glass is made by laminating a 0.090in. thick, clear plastic interlayer between two sheets of standard glass. In North America, that interlayer is typically either polyvinyl butyral (PVB) or SentryGlas Plus, both of which meet the same debris impact standards (Miami-Dade County or ASTM E1996).

The 5⁄16-in.-thick laminated glass you mention is probably going to be two layers of 1⁄8-in.-thick glass sandwiching a 0.090in. thick interlayer, and the 7⁄16-in.-thick laminated glass will probably be made from two sheets of 3⁄16 in. thick glass sandwiching the same 0.090in. interlayer. The interlayer is what stops debris from penetrating window glass and entering your home during a major storm. From an impact standpoint, therefore, there is very little difference between the thinner glass and the thicker glass on each side of that interlayer. In fact, laminated glass can be as thin as 1⁄4 in. and still meet impact standards.

I suppose a window manufacturer could argue that there is a very slight advantage in terms of impact resistance between the 7⁄16-in.-thick and 5⁄16-in.-thick laminated glass, but if it were my call, I would not base my decision on that difference.

There are potential structural, wind-load, or pressure-load advantages to using the thicker glass in the laminated sandwich, however. For instance, you can meet wind- or pressure-load requirements (mandatory in certain areas) by increasing the thickness of the glass used in the laminate. But even these requirements don’t mean thicker glass is a must. Tempering or heat-strengthening the glass can accomplish the same results. Be sure to clarify with the window representatives that they are talking about the thickness of the impact-rated glass and not the nonimpact-rated glass of the dual-pane insulating-glass unit. The nonimpact glass is simply there to contain the gas between it and the laminated glass, completing the insulating glass unit. The sacrificial glass won’t provide any additional impact protection.

View Comments

I recently had impact windows installed, the main reason was for sound abatement. Unfortunately I went with standard 5/16" glass. I would estimate only a 20% improvement on sound reduction.

Years ago, around 2007 I installed impact windows off the shelf from Home Depot myself. I'm not sure if industry standards changed, but my old windows eliminated 100% of all noise.

FYI - I used to live near an airport and train tracks, and never heard either again. I wish I had went to 9/16" on this project, but at the time I didn't realize it existed.

Windows are rather easy to install. Do you know how to drill a hole, drive a screw and caulk? Then you can install replacement windows. Don't be fooled by someone preaching how difficult it is. I used to be a carpenter, but in reality a trained monkey could install them.

The only reason I contracted out the install, is regretfully this is a condo and too many annoying people are watching. My recommendation would be to go with the thickest glass you can possibly get. 5/16" glass is completely worthless, unless of course you live in a quiet area and you're just looking for a slightly cheaper improvement.

Good luck, and do lots of research. Talk to people who actually have them, not just contractors. Remember, everyone is a salesperson these days, just looking to capitalize on a payday.

I like the way you are working!