Double-Hung Windows

Knowing your priorities will help you find the best value in windows.

Synopsis: The double-hung window remains one of the most popular window styles in the country. Contributing writer Scott Gibson breaks down the buying decision for double-hungs into four categories. The first is energy efficiency, the second is durability, the next is appearance and the final category is functionality.

The venerable double-hung sash window has been letting light and air into American homes as long as there’s been an America, and it remains one of the most popular window types in the country. And while they’ve come a long way from those early “wind holes,” you can still buy double-hungs with essentially the same chain-and-weight mechanism that made them the talk of Europe in the mid-1600s.

Double-hungs today are all about choice—and price. A budget 2-ft. by 3-ft. window with a vinyl frame and double-pane glazing costs as little as $100 at a home center. Or you can spend four or five times as much on a window like the Alpen Series 725 double-hung, built with a foam-filled fiberglass frame and triple-pane glass. Ultimately, manufacturers say, the cost of a window equals the sum of its parts. Cheaper windows use cheaper materials (vinyl instead of aluminumclad wood, for example), come in limited sizes and colors, lack custom features, and have glass with fewer coatings and higher U-factors.

What, then, is worth paying for? It depends on your priorities. Are you building an energy-conscious house in Maine, or restoring a vintage bungalow in Tennessee? Are you choosing windows for a showcase home perched on an ocean bluff, or for a modest Cape for an aging parent? A look at four key factors—energy efficiency, durability, appearance, and functionality, along with the costs associated with each—can help you choose the window that fits your needs and your budget, too.

Efficiency comes down to where you live

Hands down, the most dramatic change in window technology of the last generation has been better energy performance. This is a function of the glass itself, the internal spacers that provide a thermal break from inside to outside, coatings that control the transmission of light and energy, better seals, and more thermally efficient frames. Owing to their construction, double-hungs cannot match the airtightness of casements, and they would be an unlikely choice for a truly high performance house. Nonetheless, windows should be considered part of any house’s complete energy package.

For example, paying more for windows with low U-factors (high R-values) may actually be a cheaper path to energy savings than increasing the amount of insulation in exterior walls, says Marc Rosenbaum, director of engineering at South Mountain Co. on Martha’s Vineyard, Mass. “In new construction, really good windows might cut the cost of the heating system noticeably,” he said. “With minisplit heat pumps and really good windows, you can get by with a single zone and a bit of electric resistance in the bedrooms instead of a fully distributed heating system.” Running energy calculations on one hypothetical house, Rosenbaum found that raising window and door R-values from R-3 to R-5.6 (the same as lowering U-factors from 0.33 to 0.17) had the same effect as increasing wall insulation from R-20 to R-40.

It’s not all about heat loss. In parts of the country where heat gain is a greater concern, it may be more important to choose windows that keep out more of the sun’s heat energy—those with a low solar heatgain coefficient, or SHGC. “For most of the medium- to high-end custom homes we do, you could double or triple the thermal resistance of the glass and it would have a negligible effect on the energy performance of the house,” says Peter Pfeiffer, an architect in Austin, Texas. That’s significant from a cost standpoint, as lower U-factors generally add more to the cost of a window than lower SHGC.

In all climates, windows with low rates of air infiltration help control heating and cooling costs, but this—a result of better engineering, pricier components, and precise manufacturing—comes at a cost.

In the zone. By offering different glazing packages in the same product line, manufacturers can meet a variety of climate needs. For example, the U-factor on Andersen’s A-Series double-hung can range from 0.31 to 0.25, and the SHGC can range from 0.15 (with Andersen’s Low-E4 Sun glass) to 0.50 (with its Low-E4 PassiveSun glass).

Durability comes standard

For the past 20 years, the trend has been toward windows requiring less exterior maintenance—and it shows. “Windows are a lot better than they used to be,” says Massachusetts designer and builder Joseph Lanza. “The worst window you can buy that meets code is still pretty good.” Durability has become so standard that manufacturers who make several types of windows are reluctant to rank them, because putting one before the other suggests there’s something inherently wrong with being number 2.

“We actually don’t answer that question because we pride ourselves on bringing high-quality, long-lasting materials to market,” said Christine Marvin, marketing chief for Marvin Windows and Doors, when asked whether fiberglass or aluminum-clad windows last longer. “We never say one outperforms the other.”

Even wood is getting another chance. Jeld-Wen, for example, touts the treated pine it uses in its AuraLast line of windows as “The Wood That Does Not Rot.” AuraLast comes with a limited lifetime warranty against rot and termites.

In terms of cost, Keith Dashofy, Milgard’s senior product manager for vinyl and aluminum products, ranks frame materials in this order: vinyl and entry-level aluminum at the bottom, then wood, fiberglass, and clad products. Still, it’s the glass package that adds most to a window’s overall cost. “The glass that you use for any window today is the same glass package whether it’s in vinyl or wood or aluminum,” he says. “So while glass is a major cost driver for your overall window price, depending on what level of efficiency you’re trying to capture, the variation is ultimately going to come in the frame material.”

Today’s materials have it covered

As charming as they are, traditional windows with wood frames and sashes need regular maintenance. A number of alternatives have emerged—including vinyl; wood clad in vinyl, aluminum, or fiberglass; aluminum; fiberglass; and wood/plastic composites—that are designed to reduce or even eliminate the need for exterior maintenance.

Vinyl Windows made from vinyl extrusions won’t rot and are impervious to insect damage. They’re typically the least expensive window option and are often less expensive to make in custom sizes than other types. But they are not entirely worry-free. Vinyl expands and contracts with heat more dramatically than other materials, putting strain on seals, and dark colors can fade in sunlight. Degradation due to ultraviolet radiation is another concern, particularly in areas where sunlight is intense.

Clad Clad windows feature a vinyl, fiberglass, or aluminum skin over a wood substrate. Regardless of type, the cladding typically has a long-wearing, factory-applied finish available in dozens of colors. With no exposed wood, moisture and insects are not an issue. Wood and aluminum have different rates of thermal expansion and contraction, so the two materials must be engineered to work together as they cycle through heat and cold.

Fiberglass Windows made from pultruded fiberglass—which is formed by pulling rather than pushing a resin-and-glass-strand mixture through a die—have much lower rates of thermal expansion and contraction than vinyl, so they exert far less stress on seals. Ultrex, the trade name for Marvin’s pultruded fiberglass, is eight times stronger than vinyl and three times stronger than wood/vinyl composites, according to the manufacturer. Although on a par with clad windows for cost, fiberglass won’t rot or warp, and coatings are typically very durable, being similar to those used on metal windows.

Aluminum All-metal aluminum windows have sleek profiles, high strength, and good durability, making them a good match for contemporary designs. They don’t need painting, and the aluminum won’t rot or rust. But thermal performance can be compromised because metal readily conducts heat and cold. Milgard, for example, pitches its standard aluminum windows for houses in “mild Southwest climates” (although the company also makes a “thermally improved” version for colder climates). There are several possible finishes used on metal and metal-clad windows. The most durable are polyvinylidene fluorides, sold as Kynar and Hylar.

Paying for looks

While manufacturers appreciate that homeowners like the low maintenance of fiberglass, vinyl, or aluminum on the outside, they also recognize that most prefer wood on the inside. Marvin, for instance, offers its fiberglass Integrity windows with an interior of unfinished or factory-finished pine. Jeld-Wen’s vinyl windows can be ordered with a wood veneer interior in one of three species. Pella’s Architect series offers four unfinished wood interiors (alder, pine, mahogany, and Douglas fir), eight stained, and three painted interiors.

Color choices—both inside and outside—also abound. Whether colors cost you more depends on the manufacturer and the product line. For example, Jeld-Wen doesn’t charge any more for a colored exterior in its clad-wood windows, but it does for colored exteriors on its vinyl windows. Generally, the more expensive the window, the greater the color options inside and out. Pella’s top-of-the-line Architect Series wood windows offer 27 exterior colors; its basic 250 Series vinyl offers two (white and almond). Manufacturers can be very accommodating (Marvin once produced windows with cladding painted to match the color of a homeowner’s classic Mercedes), but the more you stray from the menu of standard finishes, colors, or sizes, the more you will pay.

In addition to a plethora of color and interior-wood choices, makers of double-hungs have expanded options for muntin, sash, and casing profiles—with a higher upcharge for a more authentic appearance. For an Andersen Series 200 double-hung, removable interior grilles add $36 to the cost of a 3-ft. by 4-ft. window, the same premium you’d pay for muntins between the two panes of glass. But a simulated divided-lite window with an exterior grille plus a removable interior grille is $180, while an outside grille with nothing inside is $108.

They’re not just for colonials anymore

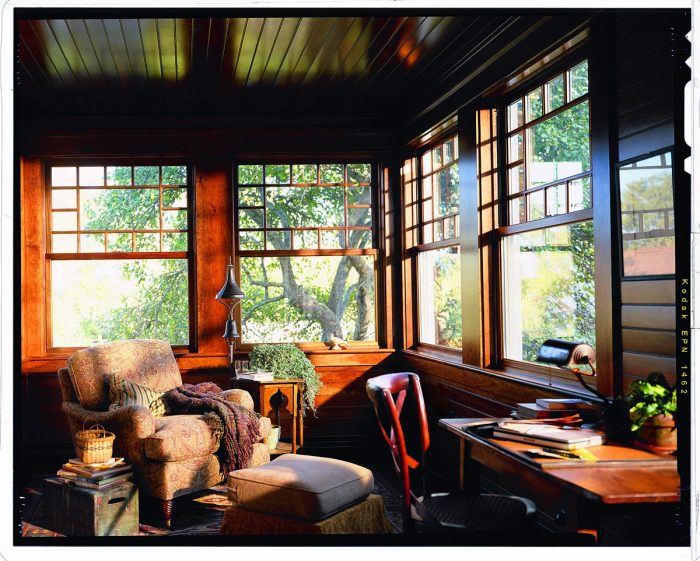

As a rule, double-hung windows are conservative in style, which makes them a good match for colonials, Victorians, and Craftsman bungalows. Window makers have responded with a variety of muntin, sash, and casing profiles; but generally speaking, the fancier the grill pattern, the higher the cost. For buyers who want to match a particular historic pattern, companies such as Kolbe promise to replicate historic details right down to brass pulley systems, beveled glass, and ogee molding profiles. Pella also offers custom sizes and features such as curved frames and stained or beveled glass.

|

Authentic alternatives. The jamb liners of Kolbe’s Ultra Series Sterling double-hung window, left, are concealed to provide a smooth interior appearance, while the chain-and-pulley mechanism on Marvin’s Ultimate double-hung is revealed for its authentic appeal. Both windows are available with radius tops. |

|

Interior options. Andersen’s A-Series double-hung windows can be ordered in 10 interior finishes and 11 exterior colors. Shown are the windows with oak interiors and prairie-style muntins.

Double-Hung Windows with Specified Equal Light Grilles – upper sash only; Clay Canyon Exterior Finish

Spanish Colonial Home Style

E-Series Architectural Collection

Commercial Hospitality

Windows that open easier and afford a better view

Now that tilt-to-clean sashes have become a staple of double-hung units, manufacturers are inventing new features to make their windows stand out. At least three companies have improved the standard lock (or “sweep”) located on the meeting rail of the window. Kolbe and Marvin have incorporated the tilt mechanism into the lock to eliminate visible tilt latches; Marvin’s Next Generation windows feature a “vent mode” that locks the lower sash with a 4-in. gap at the bottom. Andersen, meanwhile, offers a high-tech alternative in its VeriLock system, which allows monitoring of windows via smartphone or tablet.

A primary function of windows is, of course, to allow us to see out of our houses, and manufacturers have made improvements there as well, with finer-mesh screens and glazing designed to clean itself (at least on the outside). Most have a thin coating of titanium oxide that, when exposed to sunlight, loosens organic material so it can be washed away with rain. Whether self-cleaning glass is available as a standard feature or as an extra-cost option varies by manufacturer; Jeld-Wen’s, for example, comes with an upcharge of 2% to 3%.

Functionality

It’s not an open-and-shut case

Manufacturers have seized opportunities for improvement in the operation of double-hungs, primarily in locking and tilt mechanisms, but they also have incorporated features that improve ventilation and offer better control over views. Perhaps the most high-tech improvement is represented by the VeriLock sweep available on Andersen’s E-Series windows, which can notify you via smartphone or tablet if your window is locked or unlocked. This reassurance comes at a cost of roughly $134 per window, however.

Working in tandem with a Honeywell security system, sensors built into Andersen’s VeriLock can send a wireless signal telling you whether a window is locked or unlocked.

One-touch operation. The lock on Kolbe’s Ultra Series Sterling double-hung features a dual-position lever that allows the sash to be unlocked, operated, and tilted in from one location.

A more vivid view. Constructed of a finer mesh than its standard screen, Pella’s Vivid View screen allows 29% more light and 21% more airflow than typical screening.

A better blind. Marvin has introduced interior shades that slide up and down in a track that can be attached to the jamb or ordered as part of the frame. Blackout versions are available for bedrooms. The company also has a retractable screen for its double-hung windows.

To read more about durability, appearance, and functionality of double-hung windows, click the View PDF button below.