Energy Codes as Clear as Glass

The building codes for windows address both thermal and air transmission—here's what you need to know to select windows using the prescriptive path.

Synopsis: Whether windows are required or provided by choice, the code has long-addressed various safety concerns. With the rising importance of energy conservation, it has added requirements to manage the energy penalties that can come with them. In this column, building-code expert Glenn Mathewson addresses the paths to code compliance.

If not for local ordinances that would likely prohibit it, you could, in some half-baked pursuit of energy efficiency, build a house with no windows— the 2021 International Residential Code (IRC) won’t stand in your way (and people say the code is restrictive!). You couldn’t have done this in the 1800s, though. Before electric light was allowed as an exception, windows were required in order to provide natural light and reduce the use of candles and lanterns during daylight hours (largely to reduce fire risk). More recently, the need for windows to provide ventilation has been circumvented by the introduction of whole-house ventilation systems.

Whether windows are required or provided by choice, the code has long-addressed various safety concerns, from safety glazing in hazardous locations to emergency escape and rescue openings (EEROs). With the rising importance of energy conservation, it has added requirements to manage the energy penalties that can come with them.

Paths to code compliance

The energy crisis of the late ’70s brought energy-efficiency considerations to many aspects of building, including window-code provisions. Though they have evolved, window-efficiency requirements today address the same two subjects originally targeted in the code: thermal transmission and air leakage. One requirement that was later added and then dropped is window-to-wall ratio. Just as you can build a windowless house, you can also build an all-window house. This makes sense on a couple levels. For one, windows have improved dramatically and can conceivably perform better than walls in some designs (for an example of this, see “Trombe Wall Solution”). More importantly, the code is designed to address the probable, not the possible. The free market will take care of outliers like all-glass houses.

Unlike other parts of the code that are largely aimed at protecting life and limb within the well-established goals, practices, and assemblies of architecture and construction, the energy-code provisions started out as outliers. They were located in optional “appendix” chapters and specialized books, and for acceptance, they needed to be flexible in their application. It’s convenient that they are bound in scientific and mathematical principles, as this allows different methods of code compliance to be compared against each other in near equivalency. In short, energy codes are full of options. Values discussed in this article are for the “prescriptive” method, where you simply have to meet minimum requirements for each performance characteristic.

From those values, however, the performance of individual features can be traded to yield an overall equivalency, such as a higher R-value in the ceiling insulation coupled with lower-performing windows. Similarly, another method allows the estimated cost of energy consumption attributed to various subjects to be flexible, provided the sum of cost is less than a standardized estimate. This method could allow for lower-performing windows to be offset by a high-performance heating system, for example. Altogether, the energy code provides four (or more, depending on how you count) different paths to get to the code’s minimum-required efficiencies, and with the ability to mix and match assemblies and components, and even use different compliance paths for different assemblies within the same home, there are more ways to meet code for any one home than we could even begin to cover here. Here’s what you need to know to select windows using the prescriptive path.

Thermal transmission

Windows are evaluated not by R-value—the resistance to heat movement—but by U-factor, which measures heat transmission. This is a mathematical relationship, where U-factor is the reciprocal of R-value (1 / R-value = U-factor). A lower U-factor in a window is like a higher R-value in a wall. Just as the minimum R-value increases in colder climates, the maximum-allowed U-factor decreases in cold climates. Lumped together with doors under the word “fenestration,” IRC Table N1102.1.2 provides maximum U-factors (minimum performance) between 0.50 and 0.30 for climate zones 1 (warm) through 8 (cold).

U-factor only measures the non-solar-heat movement through the window assembly. Essentially, it measures heat lost from indoor air to the outside when it’s cold out, and heat gained from outdoor air when it’s hot. Though cooling is not required by the code in the way heating is, warmer climate zones still have requirements to limit the heat gain via solar radiation through the window. The solar-heat-gain coefficient (SHGC) is like the U-factor in that the lower the value, the less solar radiation the window transmits inside. The same table referenced previously provides maximum SHGCs from 0.25 to 0.40 for climate zones 1 through 4. In colder climates, there is no SHGC requirement, as the warm sun is typically welcome in the heating season and can improve a home’s overall energy efficiency.

As in nearly all code subjects, there are exceptions that address specific considerations. For example, one might want a fancy glass front door, or a window that incorporates Grandpa’s stained glass from the old family homestead. Just as provisions for safety glazing have exceptions for decorative glazing (stained glass), so does the energy code. Not specific to decorative glazing, Section N1102.3.3 allows up to 15 sq. ft. of glazing to be exempt from all U-factor and SHGC requirements in each dwelling. Additionally, Section N1102.3.4 exempts a single opaque door, often used for a front door, from these requirements.

Air transmission

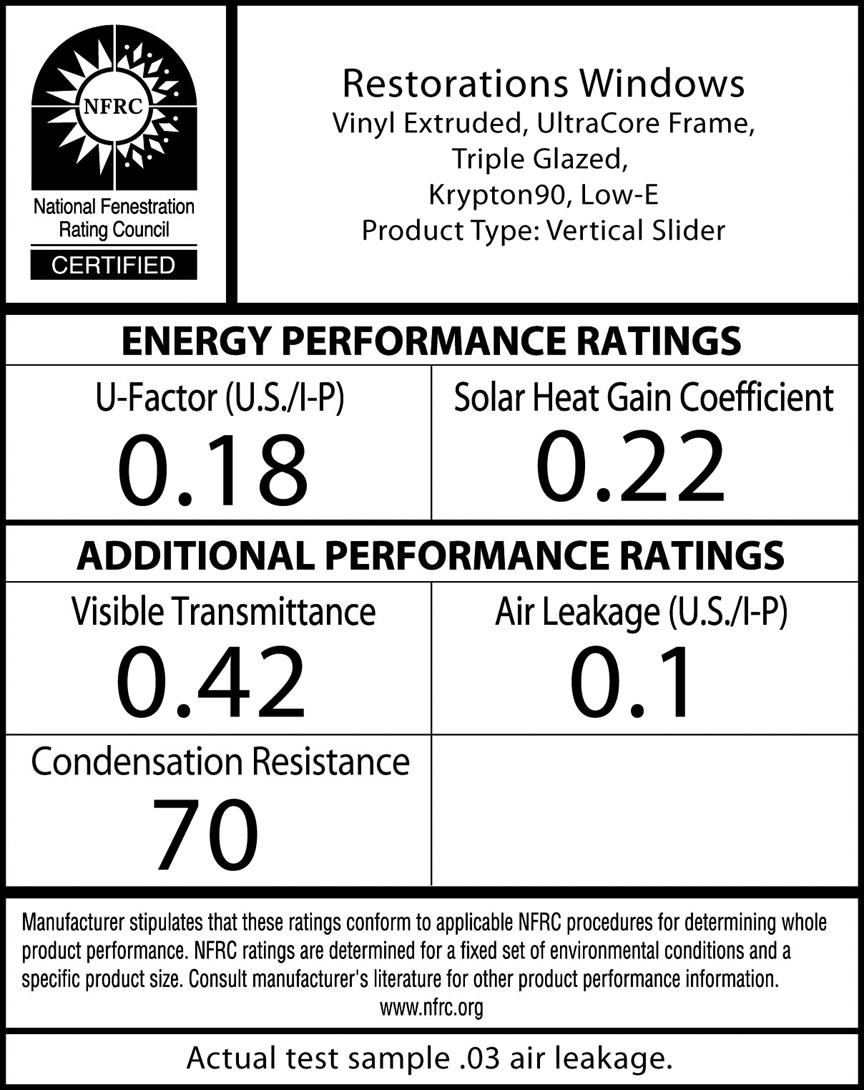

Heat can bypass all the units of measurement we’ve discussed thus far when traveling through a gap on a current of air. Factory-built windows must be laboratory tested to meet code minimums for air leakage. A window can have no greater air infiltration than 0.3 cfm per sq. ft. in accordance with the NFRC 400 standard from the National Fenestration Rating Council or with the AAMA/WDMA/CSA 101/I.S.2/A440 standard from the— what? Never mind. Large and ornate main-level, street-facing windows could be lower performing to reduce costs, while being offset by higher-performing but basic bedroom windows.

For the majority of mainstream manufactured windows, the title of that standard won’t matter. The various values and test listings of energy-code compliance are provided on the label adhered to each window, typically an NFRC label. It’s a good idea to leave those labels on the windows until after you get a final inspection. You won’t need labels, though, for site-built windows such as the stained glass you moved from the farmhouse. Site-built windows are excepted from air-leakage requirements [though not from U-factor and SHGC requirements—without testing, they’re assigned default values based on the type of construction, given in Tables N1101.10.3(1) through N1101.10.3(3)]. For new construction, subject to maximum air-leakage rates verified by blower-door tests, leaky site-built windows will be revealed and will have to be offset by tighter construction elsewhere or repaired.

Window replacements

Though I often use automobile standards as a comparison to building-code standards, the analogy falls apart when discussing repairs and rebuilds. You can’t rebuild a house to old standards like you can a car. Full window replacements (not simply reglazing a broken pane), must meet the same standards as new construction for U-factor, SHGC, and air leakage— but as always, there are options. When more than one window is replaced, an area-weighted average of all the windows can be taken for both U-factor and SHGC. This allows for higher-performing windows to offset lower-performing windows. Large and ornate main-level, street-facing windows could be lower performing to reduce costs, while being offset by higher-performing but basic bedroom windows. This design option can also be utilized in new construction using prescriptive methods without trading assemblies or evaluating energy costs. The intent is to provide maximum design and cost-analysis freedom.

Though not related to the energy code, emergency escape and rescue openings (EEROs) must be addressed when discussing window replacements. Replacement windows that fit inside existing frames often reduce the size of the clear opening below the minimum size typically required for an EERO. Inspectors have been known to derail window replacements on these grounds. However, the IRC has taken a larger look at this and allows replacements that may reduce the opening size, provided they are the largest standard size the manufacturer makes for the rough opening and either the same style or a style with a larger opening.

Though on paper this may appear to reduce safety, in reality, many older windows are very difficult to operate, have broken latches, or are sealed completely shut. In other words, old windows can have more problems than just energy loss. A new window with easy, smooth, and functional operation may yield a slightly smaller opening, but may ultimately offer more safety in addition to better energy efficiency.

Glenn Mathewson is a consultant and educator with buildingcodecollege.com.

Photo: Brian McAward

From Fine Homebuilding #299

RELATED LINKS