Installing a Mortise Lockset

Mortise locksets combine security and convenience; follow these guidelines to install one.

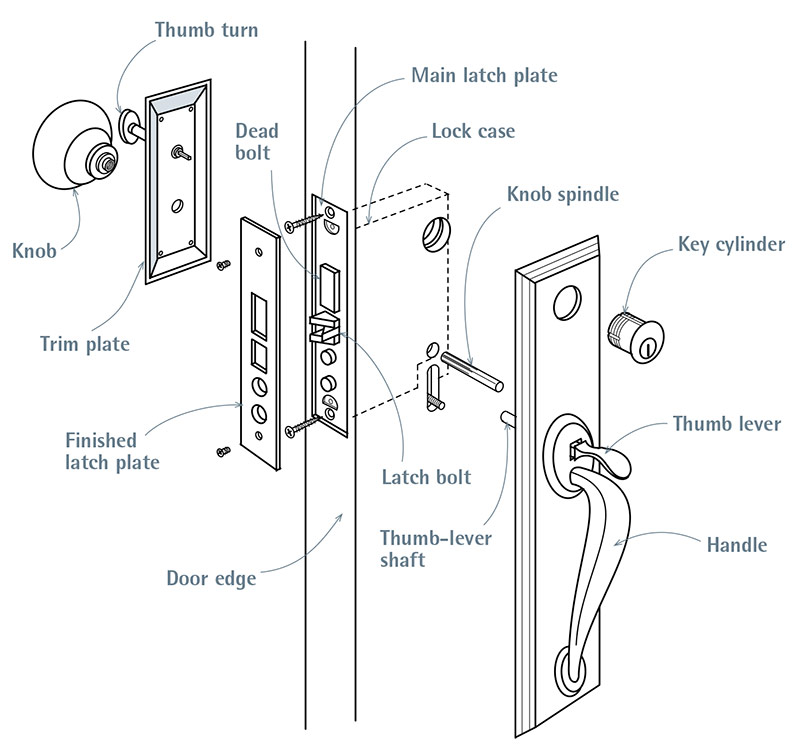

Mortise locksets house latch bolts and dead bolts in a single casing, so the door stile must be solid wood to receive this type of lock. If possible, order the door machined specifically for the lockset. If you intend to make the holes yourself, a door-boring jig will be a big help.

Mortise Lockset

| PRO TIP: Because manufacturers often create a general hardware template for several different door styles, the template provided may be inaccurate. You may not need all the holes indicated, or you may need to reposition the template to accommodate a door edge bevel. So examine the door hardware and think things through before you mark or drill the door. |

1. Using the template, mark the outline of the lock case on the edge of the door. Then mark a line in the exact center of the edge. Along this line, use a 7⁄8-in. spade bit to drill holes to the depth of the lock case. Overlap holes slightly.

2. Use a chisel to square up the edges of the lock-case mortise. As you chisel, test-fit the lock case periodically to avoid chiseling away any more wood than necessary. When the lock case fits all the way into the hole, trace the outline of the main latch plate onto the edge of the door. Use a router to mortise the latch plate. If the door edge is beveled, adjust the tilt of the main latch plate to match the bevel beforehand.

3. Remove the lock case. Using the template, mark knob/spindle and key/cylinder holes on the face of the door stile. Use a hole saw to cut the cylinder hole and a Forstner bit or spade bit to cut the smaller spindle hole, holding drill bits perpendicular to the stile. Drill the holes until the point of the bit just starts through the other side. To prevent splintering of the stile face, back the drill out and finish drilling from the other side.

4. Reinsert the lock case, and screw it to the edge of the door. Then insert the spindles, slide the escutcheons over the spindles, attach the handles or knobs to the spindles, and see if they turn freely. Once they do, screw on all the trim hardware. Typically, door handles or thumb levers are 34 in. to 38 in. high.

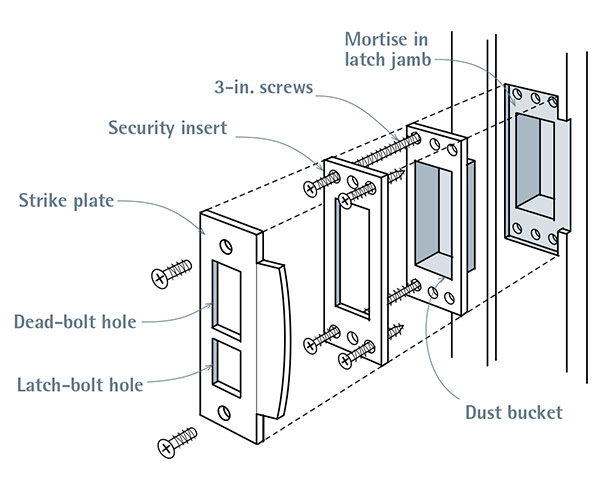

5. You also will find a strike-plate template. Depending upon the depth of the strike-plate assembly, use a router or a combination of drill and chisel to mortise the plate into the jamb. To more accurately position the leading edge of the strike plate, rub pencil lead on the latch edge; when the latch is released against the jamb, it will leave a pencil mark. For greater security, buy a unit with a strike-plate reinforcer and 3-in. mounting screws.

Reinforced Strike-Plate Assembly

frame, this strike plate can’t be dislodged by a kick.

Excerpted from Renovation, 5th Edition (The Taunton Press, 2019) by Michael Litchfield and Chip Harley

Available in the Taunton Store and at Amazon.com.