Installing and Flashing Skylights

Getting the flashing right is the key to a leak-free installation.

By letting in light, skylights can transform a room, making a bathroom seem larger, a kitchen warm and cheery, or a bedroom a place to watch the stars. And because of marked improvements in flashing and quality control, skylights can be installed without fear of leaks from the outside or of excessive heat loss from within.

Follow the manufacturer’s instructions when installing your skylight so the warranty will be honored. Here, a Velux deck-mounted skylight is being installed.

Screw the mounting brackets to the sides of the skylight curb; most brackets are adjustable. Then, with one worker on the roof and one in the attic, pass the skylight out through the opening. As the worker outside raises or lowers the brackets until the top and bottom of the unit are level, the worker inside centers the unit in the opening. That done, the outside installer screws the bottom legs of the brackets to the sheathing.

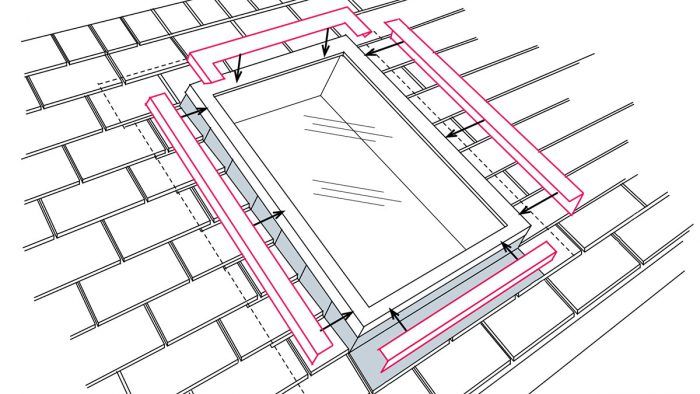

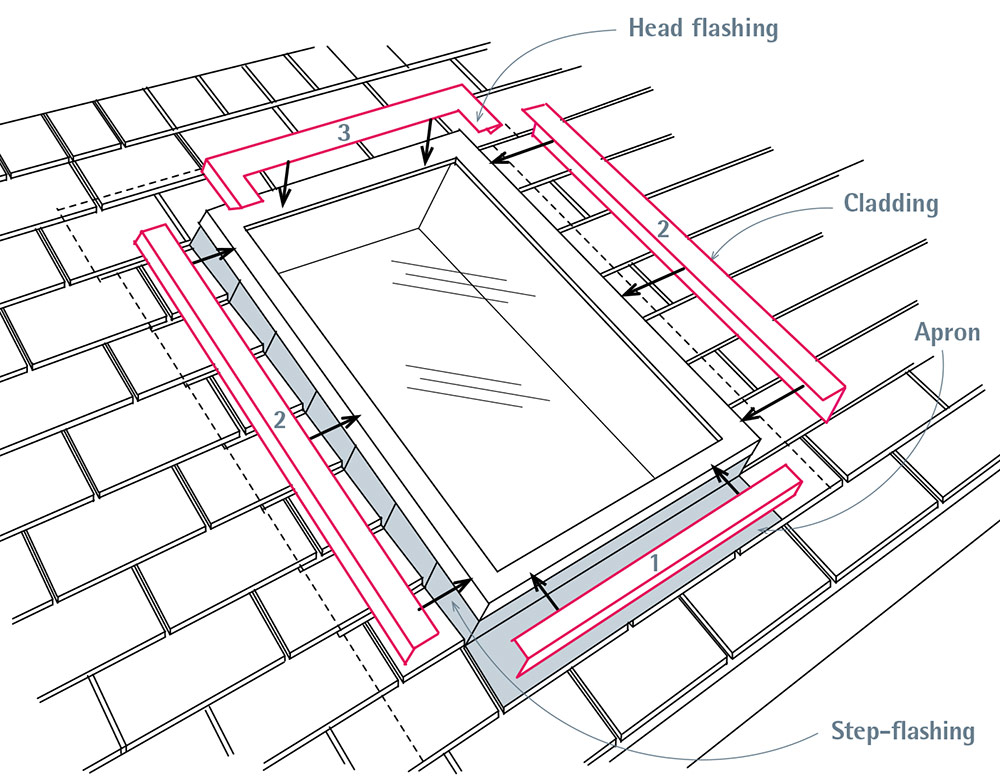

Wrapping the curb with building paper or self-adhering membrane underlayment gives you an extra layer of protection before installing the unit’s apron, side flashing, and head flashing. Apply 12-in.-wide strips of underlayment, one on each side, folding each so that it runs up onto the curb about 2 in. Apply the bottom piece first, which overlaps the shingles below, then place the side pieces and, finally, the top piece. If possible, slide the top piece of self-adhering membrane up under the building paper so you adhere it directly to the sheathing. Slit the folded strips where they overlap the curb corners so the strips lie flat, and apply a dab of roofing cement to adhere the slit pieces.

Install the apron flashing first. It runs along the lower edge of the skylight and overlaps the shingles below it. Holding the apron snugly against the curb, attach it to the curb—not the roof—using a single screw (or nail) on each side. Although it’s usually not necessary to caulk under the apron’s lower flange, follow the manufacturer’s advice. Ideally, the apron will line up with a course of shingles, but in renovation work that’s not always possible.

Install step-flashing along the sides, weaving the L-shaped flashing between shingle courses. Ideally, shingle courses should stop 1⁄4 in. shy of the curb so that water can run freely along the sides. The vertical leg of each piece of step-flashing should extend up high enough so it will be protected from rain by curb caps; the horizontal leg should extend under the shingles at least 4 in. As with all flashing, avoid nailing in the channel where water will run. Rather, nail overlapping pieces of step-flashing to the curb only and high enough so the nails will also be protected by curb caps. If necessary, trim the last (uppermost) -pieces of step-flashing so they don’t extend beyond the curb.

Install the head flashing by slipping its upper flange under the next full course of shingles above and pressing the head flashing snugly to the curb. Attach the head flashing to the curb with one screw or nail at each corner. Then install a strip of building paper—or a second strip of self-adhering membrane—over the head flashing’s flange before shingling over it. Note: Stop the flashing strip and shingles 21⁄2 in. to 4 in. above the skylight curb so there is a clear expanse of metal to clear leaves and accelerate runoff.

Installing cladding (curb caps) is the last step. These pieces cover and seal the tops of apron and side (step-) flashing and, on some models, the top of the head flashing as well. Follow your skylight’s installation guide religiously. In some fixed models, the head flashing is the last piece to go on, covering the upper ends of the side cladding pieces. Details vary, but caps snap or screw on. Better-quality units have self-sticking foam gaskets that are applied to the top of the curb before the caps are installed, which reduces air and dust infiltration.

Cladding for a Deck-Mounted Skylight

Finish off with a couple more tasks. To reflect light, light wells should be covered with drywall and painted a light color. Insulate around the light wells to reduce heat loss and condensation. Because condensation is common around skylights, cover the light well with water-resistant (WR) drywall, often called greenboard for its color. Stiffen the well’s outside corners with metal corner beads.

Excerpted from Renovation, 5th Edition (The Taunton Press, 2019) by Michael Litchfield and Chip Harley

Available at Amazon.com.