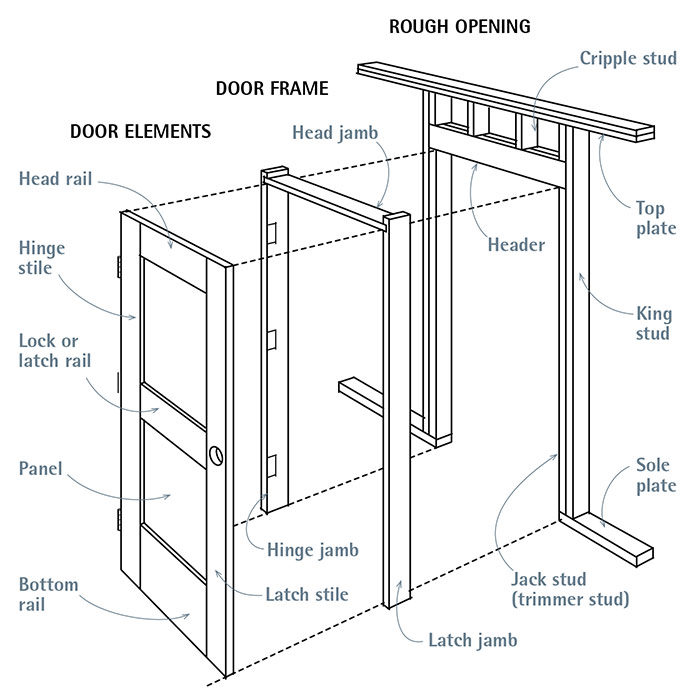

Door frames consist of several pieces: two side pieces, or side jambs, and a head jamb (or frame head), running across the top; exterior doors also have a sill spanning the bottom. (The sill may also have a threshold, but more about that later.) Jambs are further distinguished by the hardware they bear: The jamb on which the door is hung is the hinge jamb, whereas the jamb that receives the latch is the latch jamb (also called strike jamb or lock jamb).

On a common frame-and-panel door, the thicker vertical elements are called stiles; hence, hinge stile and latch (or strike) stile. Horizontal elements are called rails. Glass panes in French doors are called lights, and the thin wood strips between lights are called muntins.

Door, Door Frame, and Rough Opening

Consider the following factors when ordering doors:

Interior versus exterior. Exterior doors are generally thicker (1 3⁄4 in. versus 1 3⁄8 in.), more expensive, more weather-resistant, and more secure than interior doors. Exterior doors may have water- or UV-resistant finishes and often are insulated and weatherstripped. Don’t use interior doors outside—they won’t last.

Prehung. Prehung (preframed) doors come fitted to a frame, with hinges mortised into a jamb. Ordering prehung doors can save huge amounts of time. However, if doorways are already framed, specify unframed doors.

Knockdown prehung doors arrive with the frame head cut to the correct width and all other parts milled with correct clearances around the door, but the parts are not assembled. This allows you to trim the jambs down to the right length for your flooring and threshold heights. Suppliers will cut exterior sills to fit if you ask them to, but many contractors prefer to buy sills separately and fit them on site.

Width. Door widths increase in 2-in. increments. When door dimensions are stated as a pair of numbers, width always comes first—for example, 2 ft. 8 in. by 6 ft. 8 in. (this is sometimes abbreviated as 2868).

Standard interior doors are 2 ft. 6 in. and 2 ft. 8 in. wide. For doors leading to busy hallways, or if you need extra room for a wheelchair or walker, architects often specify 2 ft. 10 in. or 3 ft. 0 in. You can also special-order interior doors 3 ft. 6 in. wide. Narrow doors (2 ft. 0 in. to 2 ft. 4 in.) are available for half-baths and closets; even narrower ones (1 ft. 4 in. to 1 ft. 10 in.) are for linen closets and such.

Standard exterior doors are 3 ft. 0 in. wide, although side doors are sometimes 2 ft. 8 in. or 2 ft. 10 in. wide. You can special-order extra-wide 42-in. exterior doors, but their greater weight requires larger hinges, and, of course, extra-wide doors need a greater area of free space when they swing open.

Height. Standard door height is 6 ft. 8 in., for both interior and exterior doors on newer houses. Older houses (1940s and earlier) sometimes had doors 7 ft. high, so that size is still widely available. Of late, 8-ft.-high French doors are in vogue because they allow light to penetrate far into living spaces. Of course, you can special-order a door of virtually any size if you’re willing to pay for it. Salvage yards are excellent sources of odd-size doors.

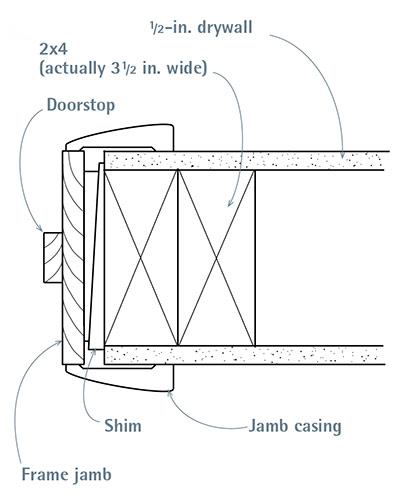

Jambs. Wall thickness determines the width of door jambs if you order prehung units. Interior door jambs are commonly 49⁄16 in. wide, which can span a 2×4 stud wall (actual width, 31⁄2 in.) with 1⁄2-in. drywall on both sides—leaving 1⁄16 in. to spare. Typically, interior door jambs are built from 3⁄4-in.-thick stock (nominal 1 in.).

For 2×6 walls (actual width, 51⁄2 in.), specify 69⁄16-in.-wide jambs, which can accommodate two wall-sandwiching layers of 1⁄2-in. drywall or—on an exterior wall—1⁄2-in. drywall and 1⁄2-in. plywood sheathing. Jambs for prehung exterior doors are usually fashioned from 11⁄2-in.-thick stock, rabbeted with an integral doorstop to receive the door when closed.

Standard-width jambs won’t work if your old house has full-dimension lumber and plaster walls or if you’re covering walls with 5⁄8-in. drywall. Your choices then become (1) jamb extensions to increase the width of standard jambs, (2) custom-milled jambs, including 1⁄8 in. extra to accommodate wavy walls or twisted lumber, and (3) split jambs, which are interlocking half-jambs that can be adjusted to the width of a wall. (An integral doorstop covers the gap between sections.)

Interior Wall Cross Section

Swing. Door swing indicates which side you want the hinges on. Imagine facing the door as it swings open toward you: If the doorknob will hit your right hand first, it’s a right-handed door; if your left hand grabs the knob, then it’s a left-handed door. Another big distinction—usually ignored—is whether a door swings in or out. The vast majority of residential exterior doors are inswings, but outswing doors are better at sealing out drafts and water. To avoid confusion when ordering doors, include a small architectural icon (sketch) to indicate which way each door swings. Some hardware is also right- or left-handed, so clarify what you want by sending the door manufacturer a photo.

| PRO TIP: Double exterior units such as French doors have an active door, which usually opens, and a semi-active one, which opens only when the throw bolts are retracted. When specifying hardware, indicate which door is active because it gets the cylinder or mortise lock. And make sure the door stile is wide enough to receive that lockset: French door stiles are often narrower than those of hinged single doors. |

Type and style. Hinged single doors are by far the most common type, but they need room to operate. If space is tight, consider sliding doors, pocket doors, or bifolds.

Try to match existing doors in the house or those on houses of a similar architectural style. In general, frame-and-panel doors tend to go well with older houses and flush doors have a more contemporary look.

If your exterior door has glass panels, they should be double glazed at the least; triple glazing is more energy efficient but costs more. Double glazing and a storm door may be a better choice. Finally, prefinish exterior doors with a UV- and water-resistant finish; at the very least, prime or seal all sides and edges.

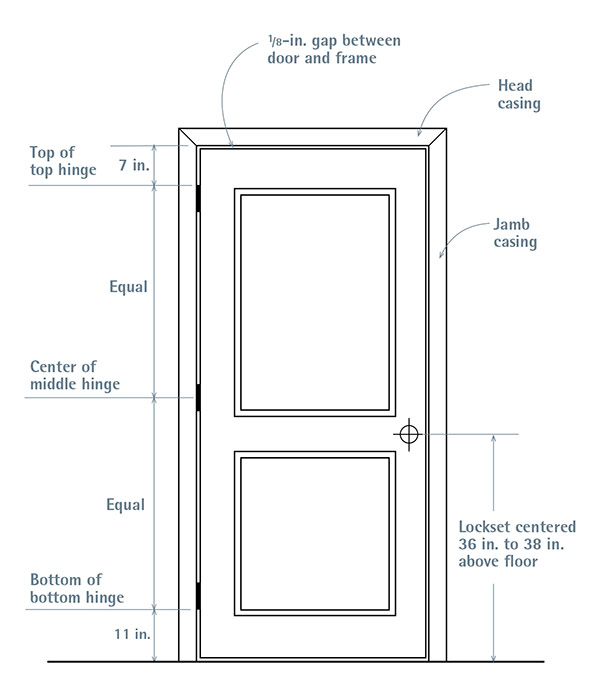

Hardware. Although hinges for prehung doors are installed at the factory, doorknobs, locksets, locks, and the like are usually ordered separately. However, if you tell the door manufacturer what kind of hardware you will be using and specify where you want the bores or mortises to go, the factory will machine the door to your specs. Then, when the doors are on-site, attach the mortised lock, bored lockset, deadbolt, and so on, to the locations you specified.

Hollow-core or light solid-wood interior doors up to 1 3⁄8 in. thick can be supported by two 3 1⁄2-in. by 3 1⁄2-in. (opened size) hinges. Wider, heavier interior doors and all 13⁄4-in. solid doors require a minimum of three 4-in. by 4-in. hinges. Extra-heavy or thicker exterior doors may need even bigger hinges with ball bearings or grease fittings.

Exterior locksets are most often cylinder locks, inserted in a hole drilled in the face of the door, or mortise locks, housed in a rectangular slot cut into the latch edge of the door. Interior locksets are almost always some kind of cylinder lock: passage locks on doors that don’t need to be locked and privacy locks on those that do.

Positioning Door Hardware

Excerpted from Renovation, 5th Edition (The Taunton Press, 2019) by Michael Litchfield and Chip Harley

Available in the Taunton Store and at Amazon.com.