Electrical Breaker Panels

The job of the breaker panel is to distribute the incoming power to the separate circuits throughout a home’s electrical system.

Synopsis: The job of an electrical breaker panel is to distribute power to the different circuits in a house’s electrical system, and to do so in a way that reduces the risk of an electrical fire. Here, electrician Cliff Popejoy identifies the different parts of an electrical breaker panel and explains how they work.

The National Electrical Code (NEC) calls breaker panels, panel boards, a name given to the earliest whole-house electrical systems—including those with switches and screw-in, Edison-type fuses— which were mounted on wooden or asbestos panels.

By the mid-1960s, breakers had almost completely replaced Edison-type fuses in new construction, so the old panel-mounted fuse boxes gave way to the metal breaker panels that are still being used today.

Although the panel shown here is based on modern NEC requirements, older service/ main panel configurations may differ. That doesn’t mean your old electrical panel necessarily requires an upgrade. If an old panel meets code requirements appropriate for when it was installed, the workmanship was good, and the panel has been maintained, then an upgrade is not required.

The job of the breaker panel is to distribute the incoming power to the separate circuits throughout a home’s electrical system, and to reduce the risk of a fire if something goes wrong with the wiring. Here’s how it works.

Panel basics

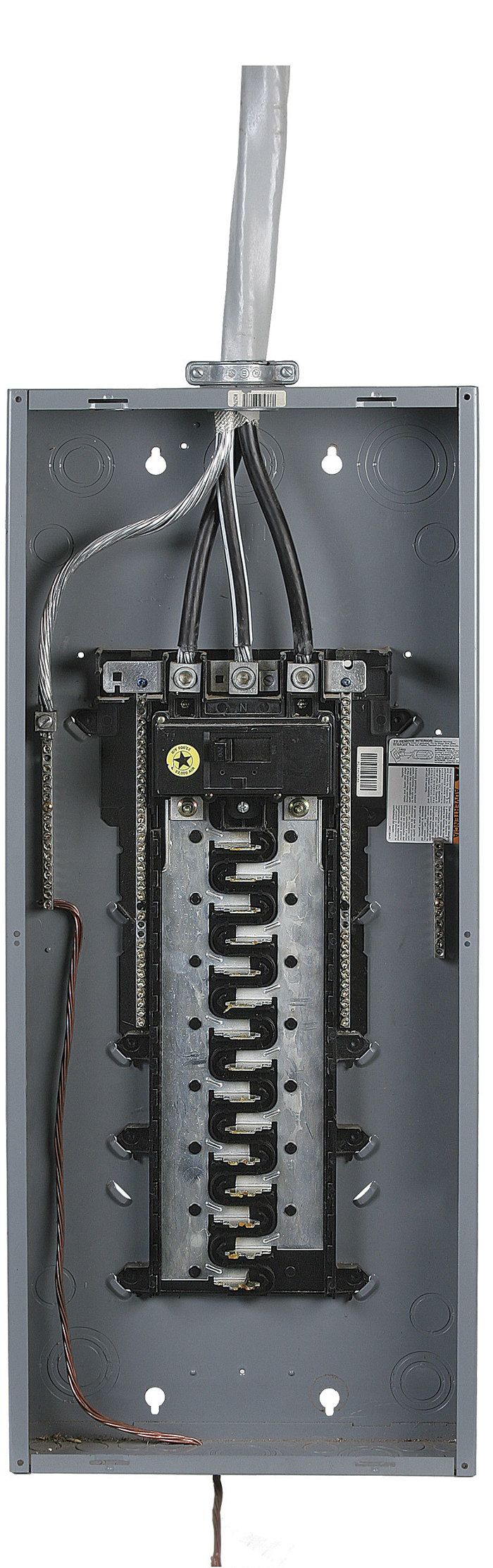

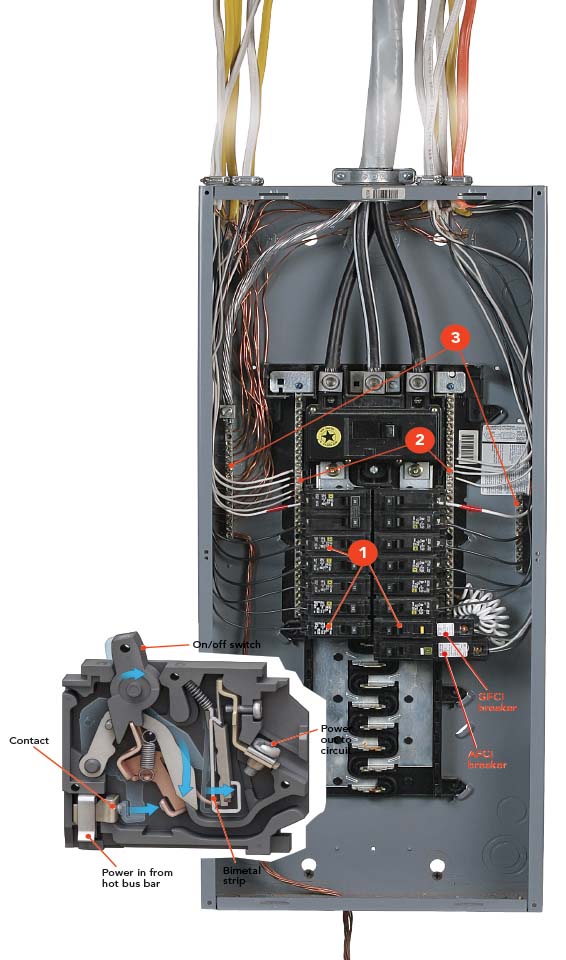

Beneath the metal cover and beyond the wires and breakers, the design of your home’s main breaker panel is simple. Although configurations vary based on panel size, type, and brand, the basic components are similar.

- Main lugs– These threaded connectors are the main point of connection between incoming electricity and the panel that distributes the power to the house. If the utility is connected, these lugs are live.

- Main circuit breaker– This is the master switch for the breaker panel. It shuts off the power to everything downstream, including the hot bus bars and all breakers mounted to them.

- Hot bus bars– These metal bars, typically made of aluminium or copper, are mounted to the panel on plastic insulators and have tabs that connect with and channel electricity to the clips on the back of the branch circuit breakers. Each of the two conductors feeds one side of the hot bus-bar section.

- Neutral bus bars– The role of the neutral bus bars, which are typically strips of aluminium bored with holes to secure and connect wires, is to act as a hub for the neutral wires returning from each circuit in the panel, completing the loop of electricity. Some panels may have just one neutral bus bar.

- Ground bars– These metal bars are the central safety hub for the panel and the ground wires for circuits connected to the panel. They create a direct path for errant power to be discharged safely to the earth.

The flow of power

With breakers installed and wires connected, the panel is ready to receive power from the utility and distribute it through the house. Here’s how the components combine to make a complete system.

- Breakers control the flow. Besides acting as manual shutoff switches, branch circuit breakers are designed to cut power automatically under hazardous conditions. Thermal-magnetic breakers are the most common type. They trip, cutting off power, in two different ways. When a circuit is carrying more current than it is designed to handle, a bimetal strip inside the breaker heats up, bends, and releases a spring-loaded mechanism to physically break the electrical connection. If there is an inadvertent connection between the hot and the neutral (referred to as a short circuit) or between the hot—or anything energized—and anything that’s grounded (referred to as a ground fault), an internal electromagnet will pull the electrical contacts apart.

GFCI breakers are required in areas where there is a greater possibility of shock or electrocution if there’s a fault. They measure the power going out on the hot and the power returning on the neutral, and disconnect if they detect a difference, preventing severe shock or electrocution. AFCI breakers, now required in most rooms of the house, use a circuit board to monitor and protect against problems stemming from arcing wires (chewed, frayed, or poorly connected wires that spark). While usually not enough to trip a regular breaker, these sparks can be enough to start a fire. - Neutrals complete the circuit. After the electricity has dropped off its energy at the load (lamp, TV, heater, etc.), it returns to the panel via the white-insulated neutral wire. The individual branch-circuit neutrals are connected to a neutral bar, which ties directly to the much larger neutral-service conductor, returning the electricity to the utility to complete the loop.

- Grounding is for safety. For tools, light fixtures, table lamps, appliances, and any other electrical devices that have exposed metal parts, there is the possibility that a frayed or damaged wire inside might touch an exposed metal part, creating a risk of shock or electrocution for someone who touches the metal. A ground conductor connected to the metal case of the device runs back to the panel, where it connects to an equipment grounding terminal bar (usually referred to as a ground bar). This allows the electricity to flow back to the panel, creating a short circuit that will trip the breaker and kill the power to that circuit. The ground bar is connected to the earth via ground electrodes, which also protect the system as a whole in the event of a lightning strike or other high-energy, high-voltage pulse traveling through the service conductors.

Photos by Rodney Diaz; drawing by Christopher Mills

RELATED LINKS

From Fine Homebuilding #257