Wiring One-and Two-Pole Breakers

Follow the guidelines for installing breakers for general-use, lighting, and small-appliance circuits as well as for larger-appliance circuits.

Installing a Standard One-Pole Breaker

Typically, 15-amp or 20-amp one-pole breakers control general-use, lighting, or small-appliance circuits; they might also run a furnace, a pool pump, or a garbage disposer. In the photo sequence shown here, a single-pole breaker is being installed in a subpanel whose power has been turned off.

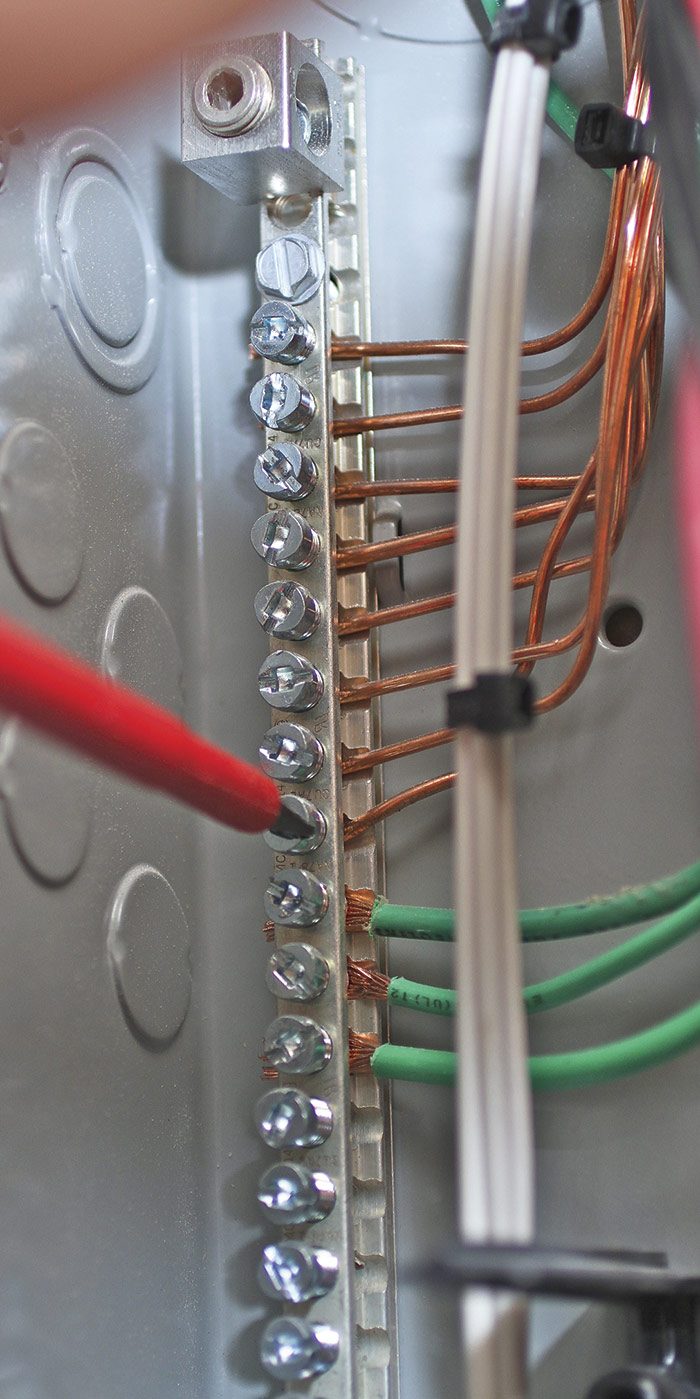

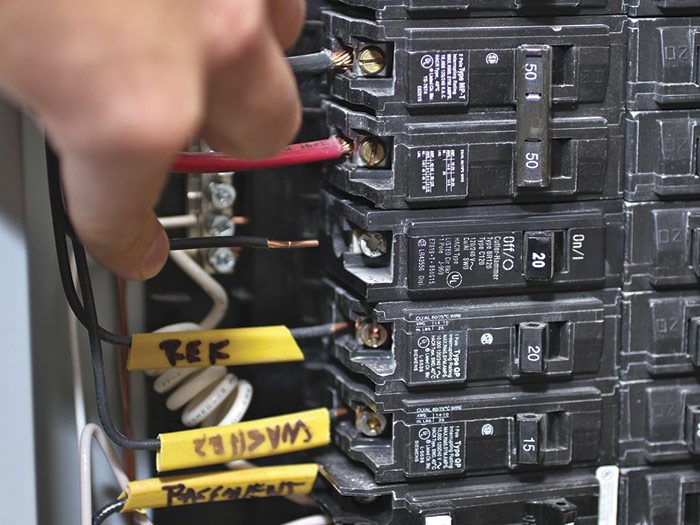

Terminate the ground wire first 1. In a subpanel, the ground will attach to a separate ground bus bonded to the metal panel. Insert only one ground wire beneath a lug screw. Note the consistent angle of all grounds in which they bend toward the bus. Look closely and you will also see that both ground and neutral wires are bundled with plastic ties to keep the box orderly.

|

|

Next strip insulation from the neutral wire and connect it to the neutral bus 2. Because this is a subpanel, the neutral bus sits atop a black plastic bracket that electrically isolates the neutral bus from the metal panel box.

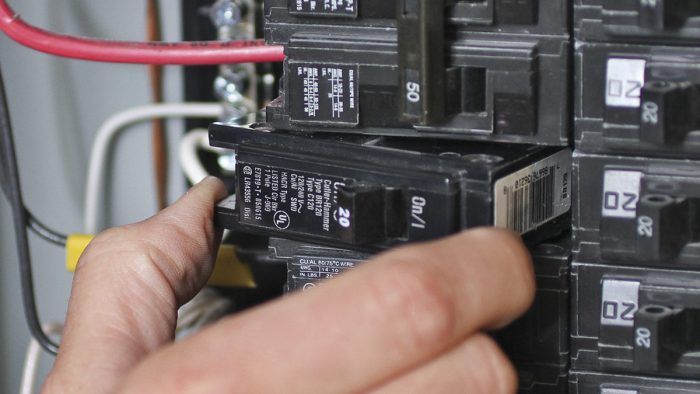

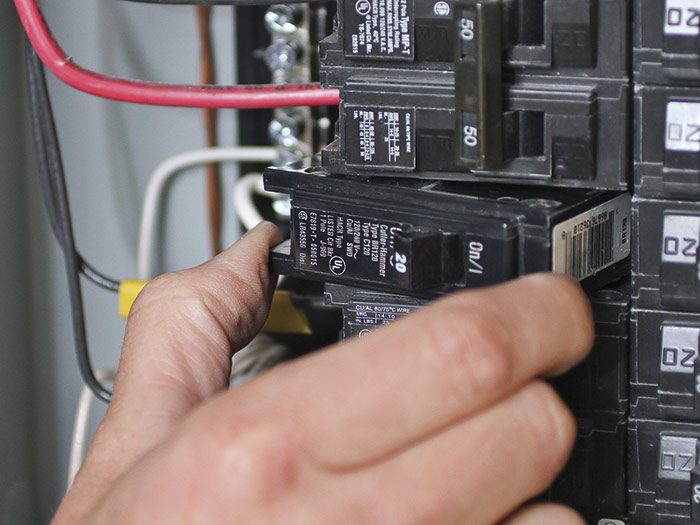

Snap the one-pole breaker onto a hot bus 3. The heel of the breaker seats on a plastic cleat and then pivots so that its jaws engage a metal bus sticking up. Press down to seat the breaker securely. Strip 3⁄8 in. to 1⁄2 in. of insulation from the end of the hot wire, then connect it to the lug screw on the end of the breaker 4. Note: Before attaching the hot wire, slip on the labeled slug of sheathing that identifies the circuit it feeds. Tighten the breaker lug to secure the hot wire.

|

|

Before flipping on the breaker, use a multimeter to test the new circuit for dead shorts, as described in “Trade Secret.” Once you are certain that the circuit has no shorts, remove a breaker-knockout from the subpanel cover, replace the cover, energize the subpanel, and flip on the new breaker.

Installing a Two-Pole Breaker

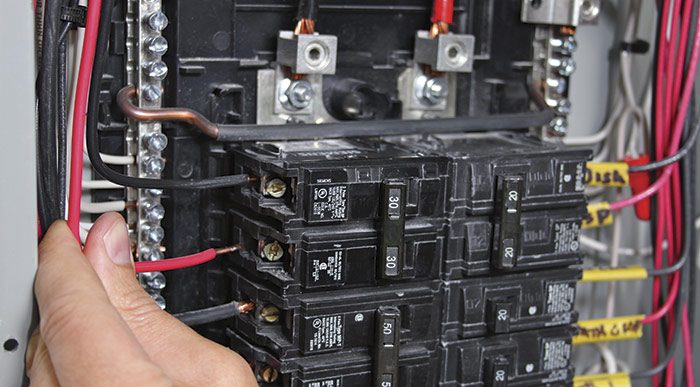

In residences, two-pole breakers typically control ovens, dryers, ranges, AC condensers, and other big energy users. The photo sequence at right shows a 30-amp, two-pole breaker being installed in a subpanel. As 120v/240v wiring tends to be appliance-specific, this circuit feeds a dryer receptacle. As the dryer’s electronic components need 120v, this 30-amp circuit was wired with 10/3 w/grd Romex cable. In addition to two hot wires, the cable contains a neutral wire and a ground.

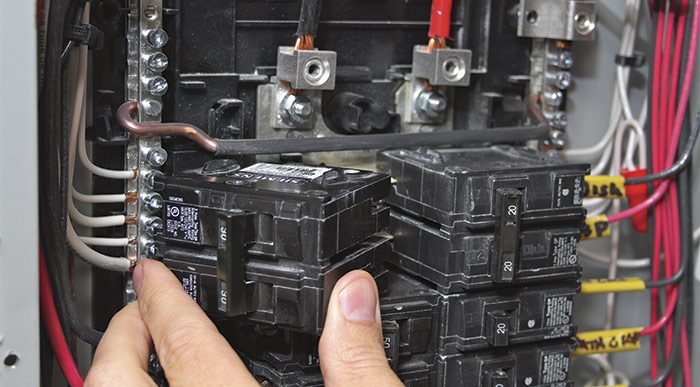

After calculating that the electrical system had sufficient capacity to add a 30-amp circuit and that there was room in the subpanel for a double breaker 1, the electrician turned off the subpanel breaker in the service panel and then tested the subpanel to be sure the power was off. That done, he removed the panel cover, removed a knockout in the panel box, installed a cable connector and fed 10/3 w/grd cable through it, tightened the cable connector, and removed the cable’s protective sheathing.

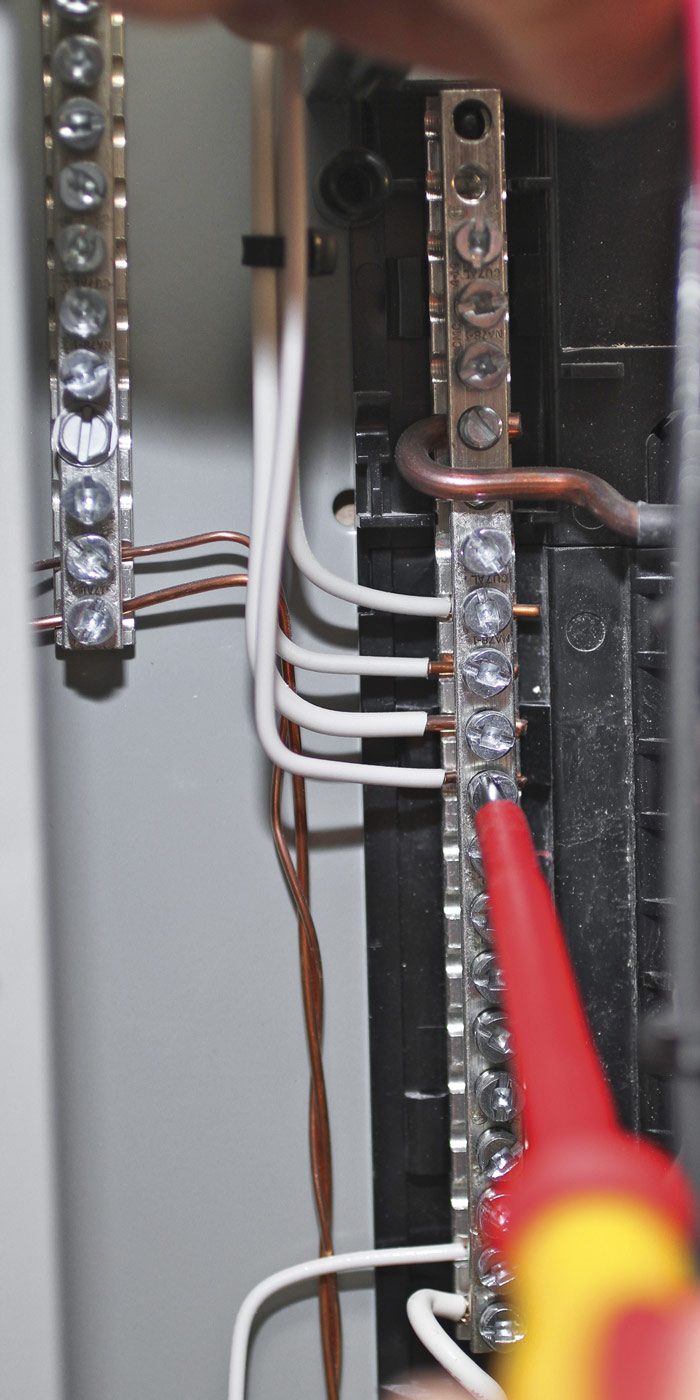

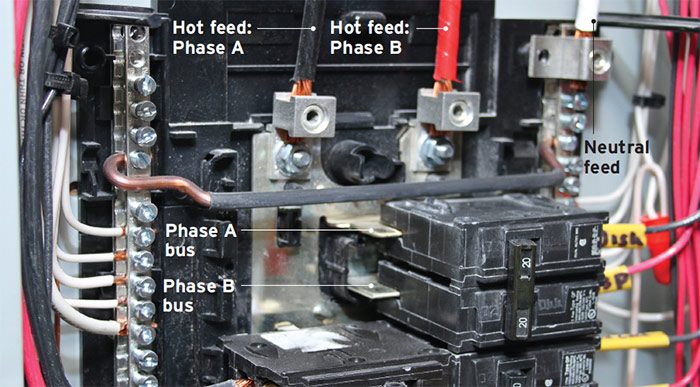

He terminated the cable’s bare ground wire at the subpanel’s ground bus, stripped insulation from the end of the neutral wire, and terminated it at the neutral bus. Before snapping a two-pole breaker onto hot buses 2, he made sure that it would land on a correct A-B bus position, that is, that the top jaws of the two-pole breaker would connect to a Phase A bus and the bottom jaws to a Phase B bus.

After slipping a labeled slug onto the cable’s black hot wire, the electrician terminated it to the breaker’s upper lug, then terminated the red hot wire to the breaker’s lower lug 3. He tightened both screws to ensure solid connections, then used a multimeter to test the circuit for dead shorts, as described in “Trade Secret.” Finding no dead shorts, he removed two breaker knockouts (two-pole breaker) from the subpanel cover, replaced the cover, energized the subpanel, and flipped on the new breaker.

Excerpted from Wiring Complete, 3rd Edition (The Taunton Press, 2017) by Michael Litchfield and Michael McAlister

Available in the Taunton Store and at Amazon.com.