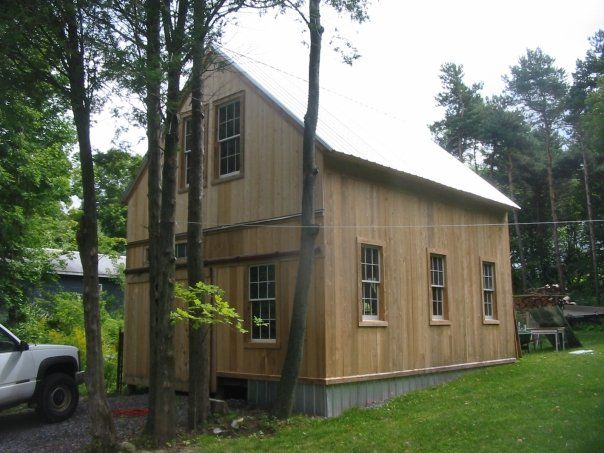

The frame footprint is 20×24, The frame was constructed using four bents using local hemlock. Each post of each bent corresponds with a reinforced sonatube which also supported the 2×10 floor. All the joinery was done with a worm-drive saw, a hand saw, a drill, and a couple chisels. Pretty simple. I had a bunch of buddies come out and help me raise the frame. As you can tell from the pictures, it was pretty soggy, and the timbers were wet. The principle rafters were green 8″x12″x20′ and were supposedly 800 lbs each, but 12 guys with a rope raised them no problem. I drew up the plans in July and raised the frame on October 14th, winter was fast approaching so I sheathed the whole thing in OSB and put on the metal roof. The next spring I installed some salvaged windows from a house in southern Maine I got from my father-in-law and sided the building with 1×8 hemlock. Looking forward to an excuse to cut another frame.

View Comments

Nice work, Dan. Looks like a sweet place to work.

Chris

Dan,

What a great project. Looks like it turned out beautifully. Those rafters are massive! Isn't it fun to do a project with friends? True spirit of timber framing in my opinion. I know what it is like to work in the rain also. It rains an average of 15 FEET / year here in Ketchikan, Alaska. Shelley

wow im considering working on this

wow the stairs look awesome

great place to work in