Teach an Old low end Table saw, New life in high end use.

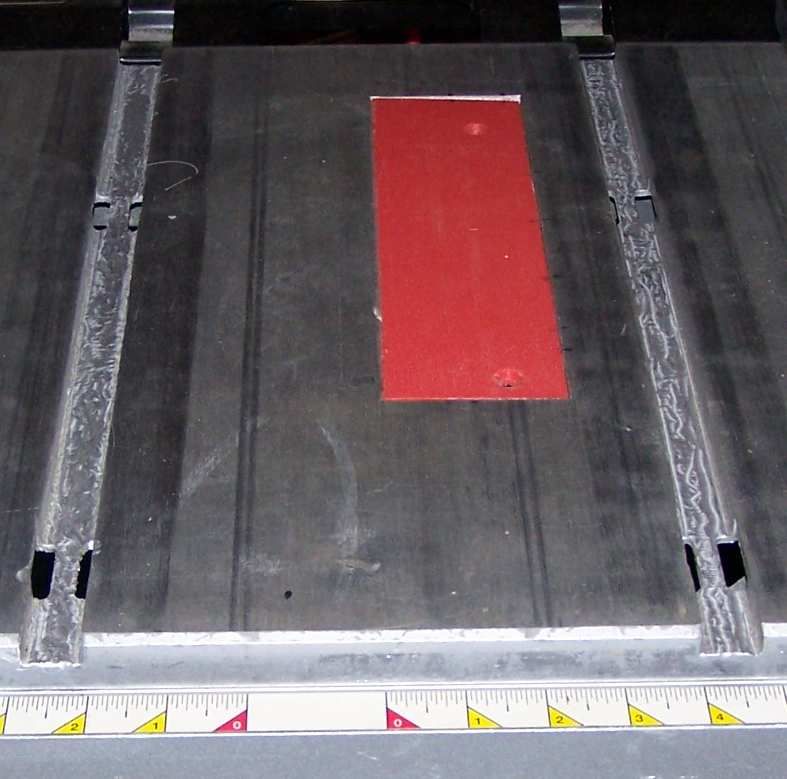

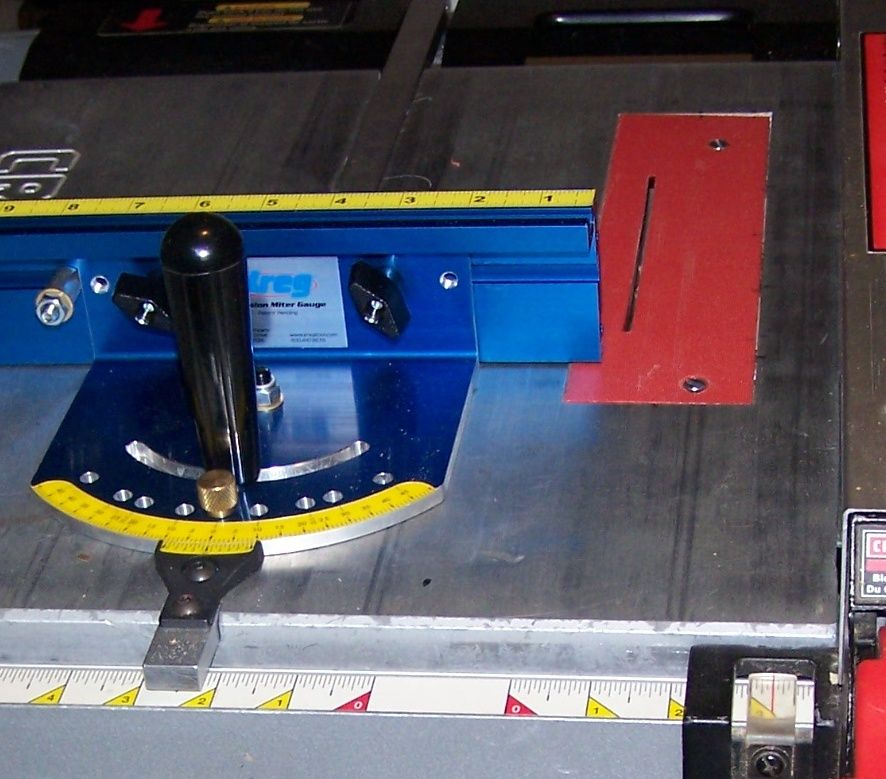

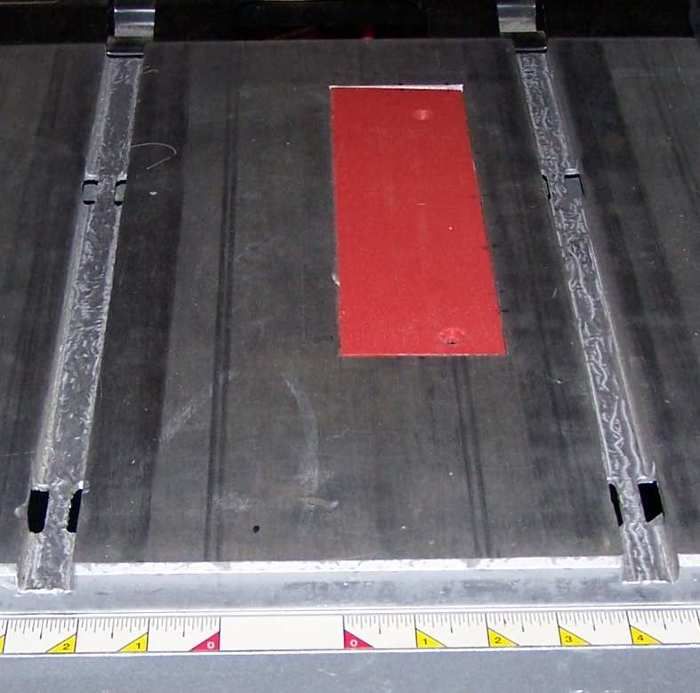

For those that have the old Table lower end Table Saw, make it work for you again. I got this Hand-me-down ruff construction Table Saw from my father-in-law, he had just spent almost $2000 on a new high end one that could make the cuts he wanted to make. After examining the table saw I found several minor flaws in the make up of the it, the saw blade was out of alinement by a 1/4″ from front to rear of the blade, and the Miter Gage that came with the table was far to loose to ever get a fair cut, it slopped around in the maunfactures channel like a compact car on a four lane highway with no markings. The Table saw top is made of aluminum, I used a Dremel, soft metal bit, and guides to make the channel 3/4″ wide to fit my new higher end Kregg Miter Gage. After clearing the channel treat it once with Teflon lube to reduce any friction for better movement of the Miter Gage. Save cost on zero clearence inserts by getting a couple low cost high density plactic cutting boards and making several inserts out of a single board, they come in many colors, I prefer the red to note out danger areas.

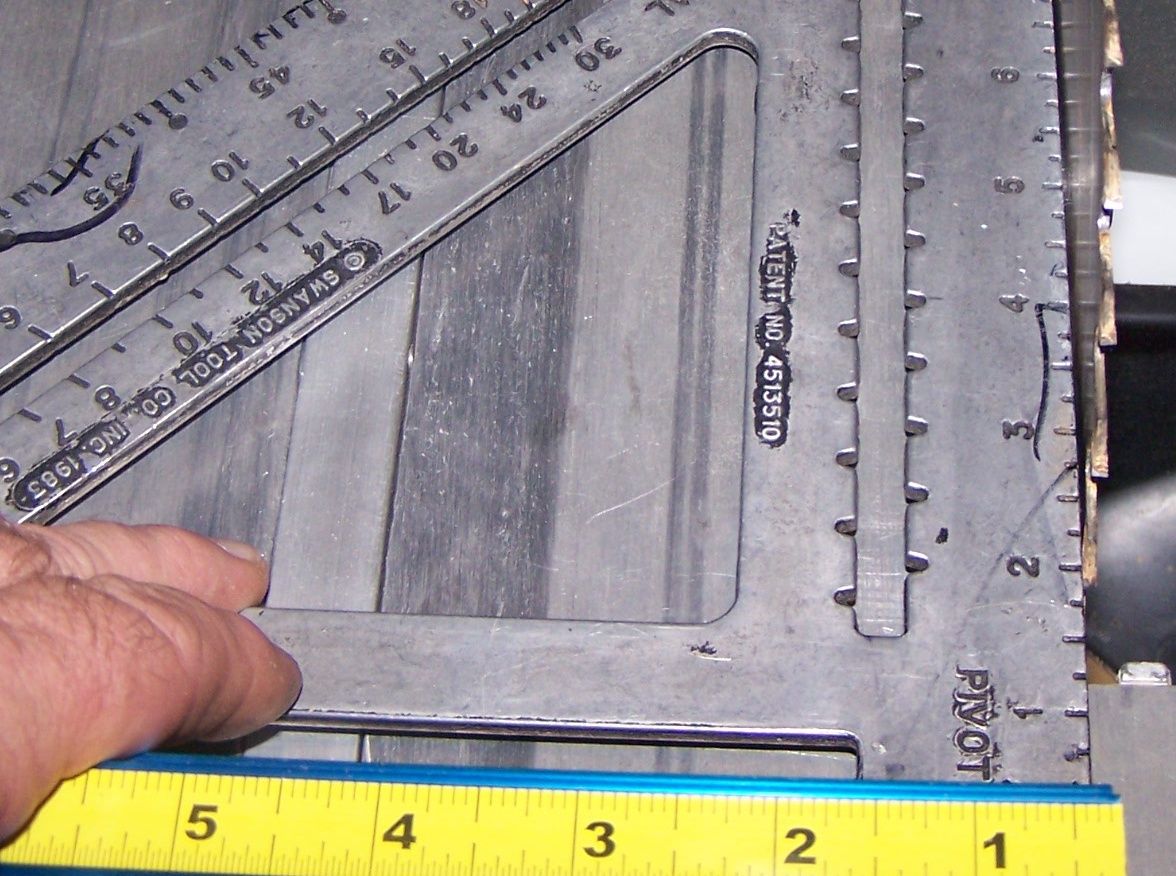

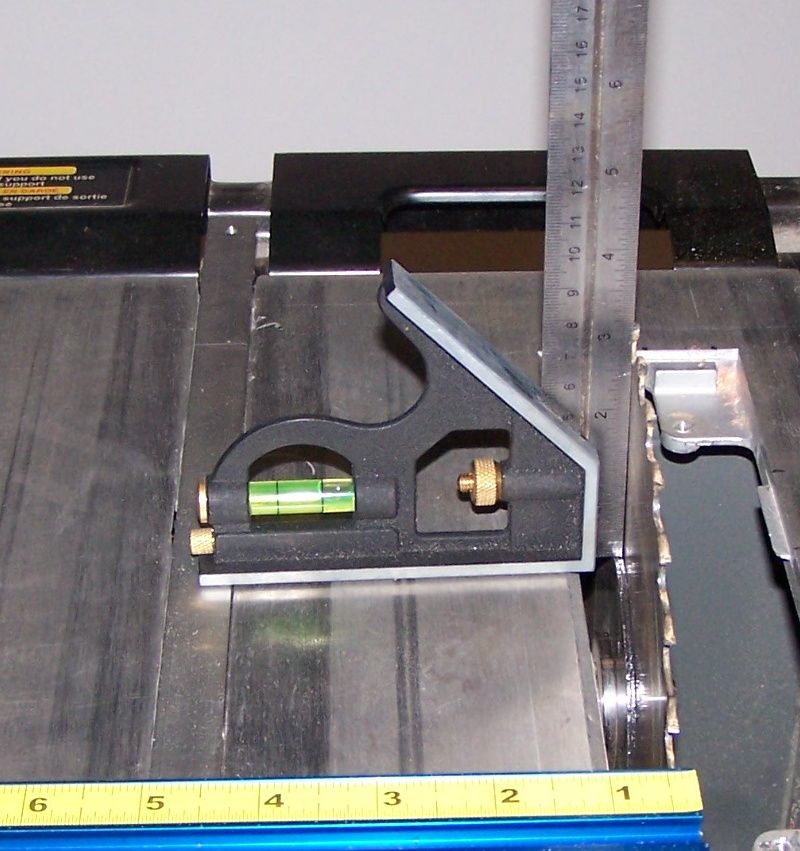

After the up grades are done tune-up the table saw for use checking and making adjustments to saw, after all it was a ruff use saw transported all over in the back of a truck. Chances are more likely than not, it is out of alinement. I found mine to be out by 1/4″ from front to rear and was also over mitering the angles on the tilt. Correct and keep a check on these even on high end machines.

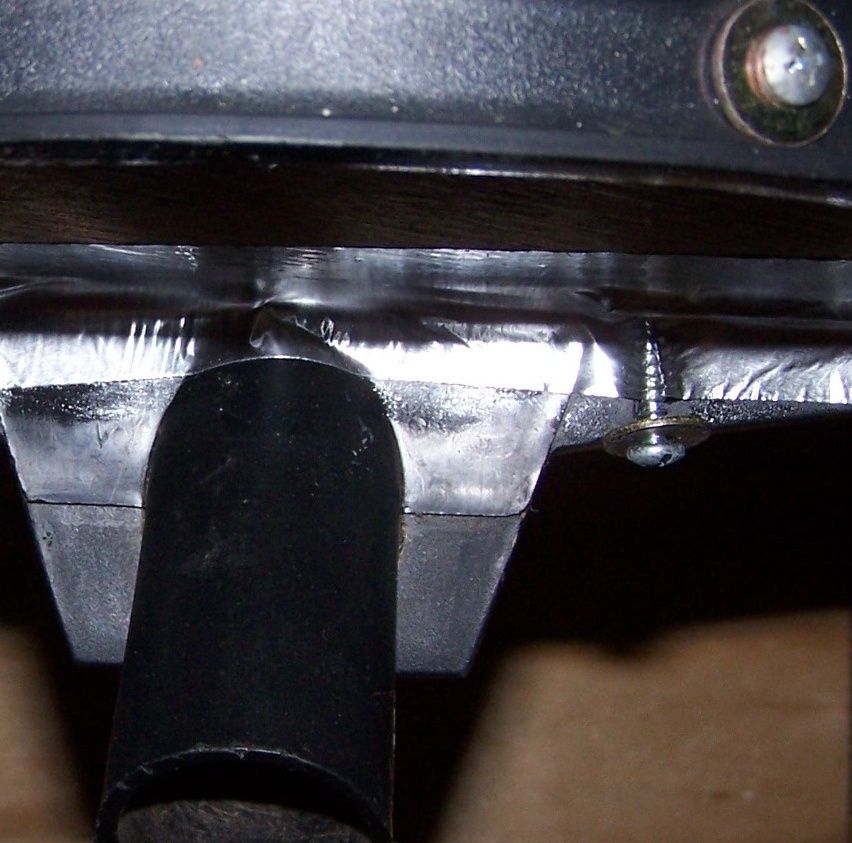

Since this will no longer be moved from site to site the drop bag for dust collection that comes with most of these Table Saw can be done away with. Cut a circular plug to fit the drop hole router a opening to fit your dust collection system and mount a off the shelf nozzel to it for any future use, this ensures that you won’t have to hunt one down when you wish to use the Table Saw