As I prepared to pour concrete steps it occurred to me that it would be difficult to screed these steps because, for each step, there were only two form edges: the riser form and the right end at right angle to the riser form. A screed board needs two registration points, typically 2 boards which are parallel to each other.

Then I realized the riser for the next step up (or the top edge of the stoop pad, in the upper step’s case) could be that parallel edge.

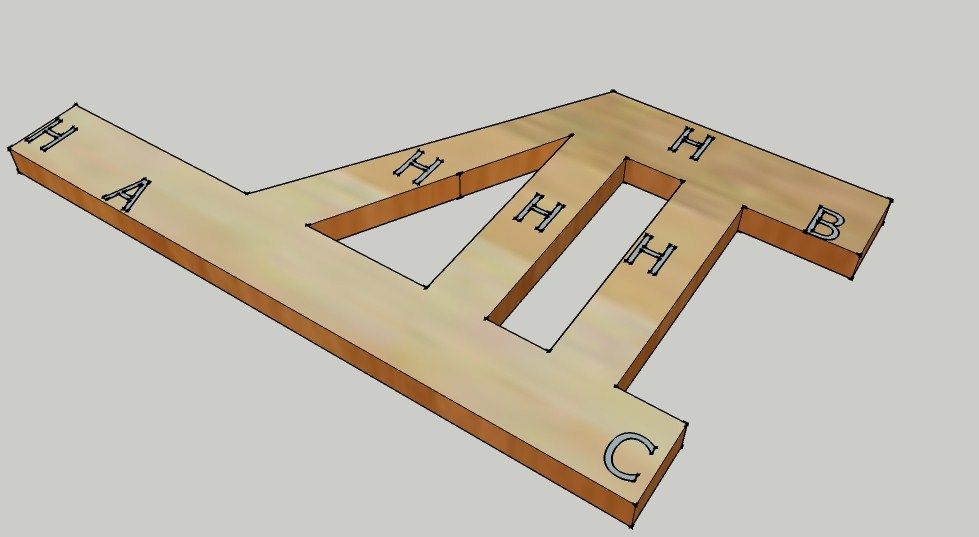

The SketchUp drawing shows my solution:

I cut this tool from 3/4″ plywood. Point A would rest against the riser form below the tread being screeded. Point B would rest on the edge of the riser form above the tread being screeded. Corner C would press against the bottom edge of the upper riser form. The distance from A to C would be equal to the tread length. The distance from B to C would be equal to the rise of the step. Points H show hand holds. Note that the corner C is undercut to keep any overhang from the upper stoop from preventing proper fit.

To use this screed, move it from side to side along the step you are working on.

View Comments

Todj57

very clever. Can you post a sketchup drawing that shows a section through the steps and formwork, with the stepped screed in position?

Chuck