Obtaining the right-size shims for a job can be quick, easy, and precise if you put in about 10 minutes’ preparation. Begin with the shim stock.

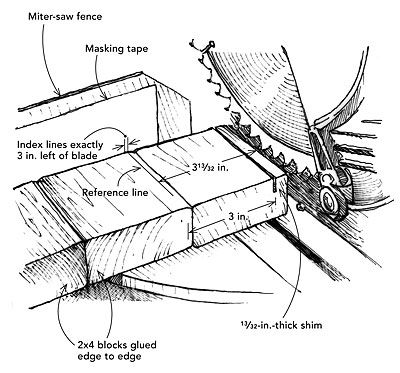

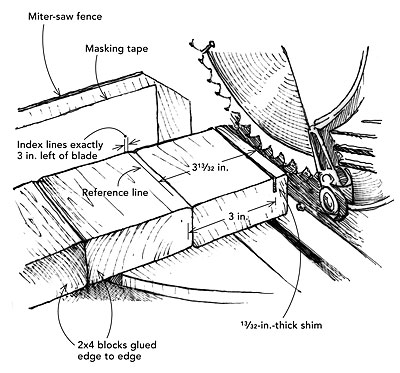

A proper shim has grain running its entire length—no end grain allowed. To that end, I glue 3-1/2-in.-long 2×4 blocks together edge to edge, as shown in the drawing. The number of blocks depends on the length of bar clamps available for gluing. I label the glued pieces “Shim Material” so that this wood isn’t used for something else.

Next, on a piece of masking tape affixed to the miter-saw fence, I draw index marks exactly 3 in. left of the blade. These marks represent both sides of the sawcut. If I wanted to cut a shim 13/32 in. thick, I would mark the shim material at 3 plus 13/32 in. from the right end, as shown. Then I would align the mark on the wood with the right index mark on the miter saw. When I cut the wood, a piece exactly 13/32 in. thick is the result.

It’s also easy to cut wedged shims this way. A useful rule of thumb is that for every mitered degree you cut through a 3-1/2-in.-wide piece, the wedge becomes 1/16 in. thicker on one end than it is on the other.

Nils Omholt, Sterling Heights, MI

Click the "thumbs up" button above to vote for this tip. Help us choose Fine Homebuilding's top-10 window and door tips.