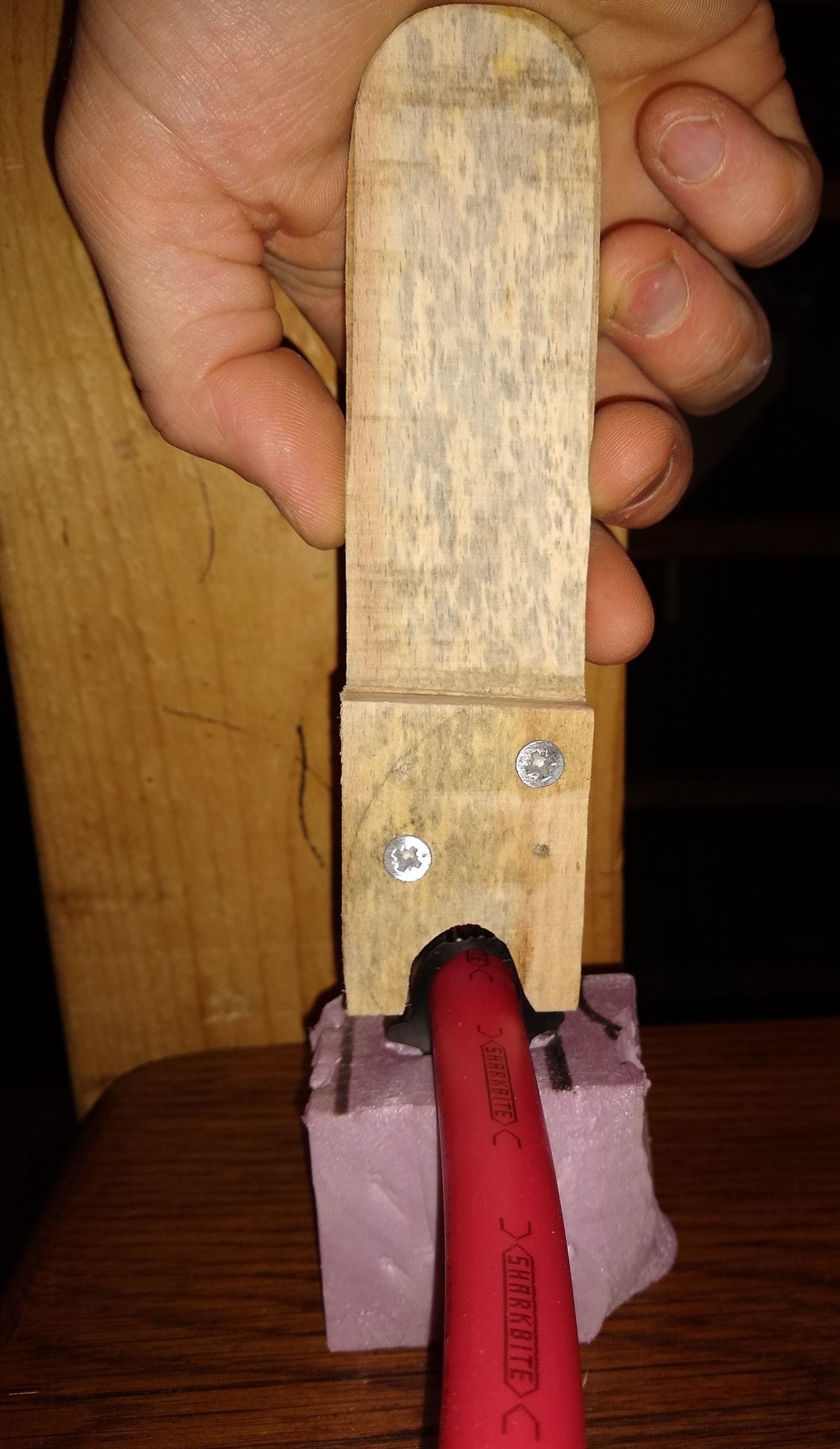

My wife and I are building our own home. We decided to do underslab radiant piping for heat. Seeing as it’s a one and done job, I couldn’t justify spending a couple hundred dollars on a foam board stapler. After stapling down about 200ft my fingers were killing me. So I got some wood scraps and cut and shaped them into a staple “pusher”. It perfectly fits the profile of the staple and goes right around the PEX on the way in. All of the pushing strain was transferred to the palm of my hand, rather than fingertips, and I was able to finish the job pain free.

View Comments

I was about to design one when I saw what the staplers cost, but here it is! Thanks for this! I'm doing pex underfloor for a tiny house. This was just what the doctor ordered.