Buyer’s Guide to Blown-in Insulation

Learn about the R-values, costs, and applications of blown-in cellulose and fiberglass insulation.

This article has been updated to reflect 2022 prices.

Loose-fill and blown-in insulation materials include fiberglass, cellulose, and (less commonly) mineral wool. Because blown-in products fill all the nooks and crannies of the framing bays where they are installed, performance is typically much better than with batt insulation.

When blown-in insulation is installed on an attic floor, it is referred to as a loose-fill application. When blown-in insulation is installed in a closed framing cavity, it’s possible to achieve higher insulation densities than can be achieved on an attic floor.

Dense-packed cellulose or fiberglass allows less air movement and has a higher R-value per inch than insulation installed at a lower density.

Because installing blown-in insulation requires special equipment, most builders subcontract the work to an insulation contractor. Although insulation blowers can be rented, most machines from big box stores are usually underpowered models that are unable to achieve the high densities required for insulating closed cavities but are are usually adequate for loose-fill installations, such as on an attic floor. Some equipment rental businesses that specialize in renting to large scale commercial contractors rent out smaller industrial blowers like the Krendl 425 or the Intec Force series that can be set up to achieve cellulose densities of 3.2 to 3.5 lbs per cu. ft.

Blown-in fiberglass

R-Value: R-2 to R-4.2 per in.

Cost: About $1.95 to $2.60 per sq. ft., depending on installation and density

Application: Above-grade walls, ceilings, and vented roof assemblies

Blown-in fiberglass consists of chopped glass fibers (and in some cases, an adhesive). The R-value of blown fiberglass increases with density and ranges from R-2.2 to R-4.2 per in. High densities also help to lower air-infiltration rates.

Like cellulose, fiberglass can be blown into a closed cavity through drilled holes, installed behind air-permeable netting stapled to studs, or blown into open framing cavities, if the product includes adhesive. Among brands of blown-in fiberglass that include an adhesive, perhaps the best known is Johns Manville’s Spider. Spider fibers are fine and short, and special spray equipment adds a polyester-based liquid adhesive during installation. Dry Spider fibers (without adhesive) also can be installed behind netting or dense-packed into wall cavities.

Typically installed on an attic floor, loose-fill fiberglass has a lower R-value per inch (R-2.2 to R-2.7) than any other common insulation product, so it’s best applied in attics that have enough room at the eaves to accommodate a very deep layer—as much as 16 in. to 26 in. Although cellulose is considered the better option for walls due its ability or manage moisture and reduce drafts, the cost to install R-19 to R-21 blown-in fiberglass in a 2×6 wall is around $1.75 per sq. ft. To reach R-38 in an attic, you’ll pay around $1.95 to $2.25 per sq. ft.

Blown-in cellulose

R-Value: R-3.2 to R-3.8 per in.

Cost: About $1.50 to $2 per sq. ft., depending on installation and density

Application: Above-grade walls, ceilings, and vented roof assemblies

Between 75% and 80% of the weight of cellulose insulation consists of ground-up newspapers. The shredded paper is mixed with one of several fire retarders, most commonly borate.

The insulating value of cellulose is comparable to that of fiberglass batts; however, because cellulose is more resistant to airflow than fiberglass, it performs better. In a closed cavity, cellulose should be installed by the dense-pack method — that is, to a density of at least 3-1/2 lb. per cu. ft. When cellulose is installed in an existing building with empty stud cavities, it is usually blown through holes drilled in the exterior sheathing. This work typically requires the temporary removal of some of the building’s siding.

Cavities in a new home can be insulated using one of four methods:

1. Damp-spray cellulose—a mixture of cellulose insulation and water—can be sprayed into the open wall cavities before drywall is installed.

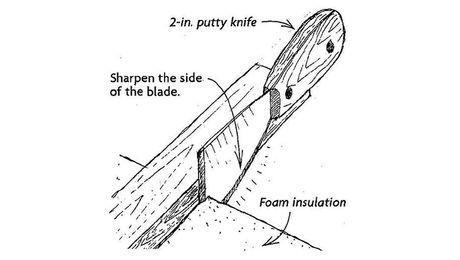

2. Dry cellulose can be installed through holes in air-permeable netting that has been stapled and sometimes glued over the interior face of the studs (photo left).

3. Dry cellulose can be installed through gaps in the interior drywall.

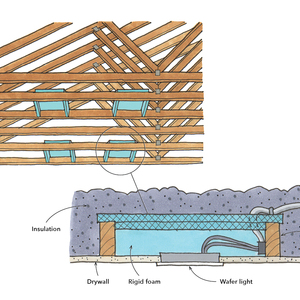

4. Dry cellulose can be installed through holes in rigid-foam insulation that has been installed on the interior side of studs or rafters.

Cellulose insulation is inexpensive. The cost to install R-19 or R-21 of dense-packed cellulose in a 2×6 wall is $1.75 to $2.50 per sq. ft. depending on the type of siding or whether or not access is created from the interior. Loose-fill installed in an attic to R-38 is between $1.50 and $2 per sq. ft. Proponents of green building appreciate its high recycled content and low embodied energy. One disadvantage of cellulose is that it doesn’t respond well to moisture. Because cellulose is able to absorb and hold a lot of water, roof or plumbing leaks may go unnoticed longer than with other insulation materials.

RELATED STORIES

- How to Choose and Install Blown-in Insulation

- Blown-in Insulation for Attics: Fiberglass vs. Cellulose

- Five Types of R-Value

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Loctite Foamboard Adhesive

Foam Gun

Utility Knife