It’s Time to Switch to Cap Fasteners

Gone are the days of hammer tackers for installing housewrap and roof underlayment.

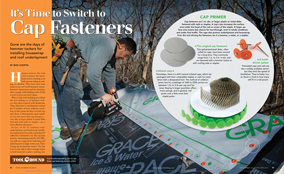

Synopsis: Once upon a time, a hammer tacker was the best tool for attaching housewrap and roof underlayment to house sheathing. Now, according to builder Mike Guertin, it’s time to switch to cap fasteners. These tools are not only more effective but also are what you need to comply with manufacturer instructions and building codes. Caps are 1-in-dia. or larger plastic or metal disks fastened with nails or staples. The cap increases the fastener’s surface area, meaning less chance for tearing even under windy conditions or foot traffic. Pneumatic cap staplers are available in two styles: tools that attach lighter weight 20- and 21-ga. staples; and tools that attach 18-ga. staples, which have more holding power. Pneumatic cap nailers also are available. Additionally, National Nail makes a hammer tacker that has a manual cap-feed trigger.

Hammer tackers, the tools used to fasten the membrane you’re counting on to back up your siding or roofing, are obsolete. They don’t meet most house wrap and underlayment manufacturers’ instructions and, by extension, don’t comply with building codes. If this is news to you, you aren’t alone.

When I talk with building pros about the now-fading era of hammer tackers, they often respond with skepticism. They claim they’ve used hammer tackers for X number of years without a problem, or they point out that everyone else uses them. Unfortunately, most installers are not aware that cap fasteners — 1-in.-dia. or larger plastic or metal disks fastened with nails or staples — are a more effective alternative.

In fact, of the 52 synthetic-roof underlayment and house wrap installation instructions I recently researched, 43 called for a minimum 1-in.-dia. cap-type fastener. And starting with the 2012 IRC, cap nails are required for fastening roof underlayment in high-wind areas. Have I hung up my hammer tacker? No, but I use it now only to drive enough staples to hold material in place, making sure always to place fasteners where they will be covered.

I suspect that aside from extra cost or just not realizing that hammer tackers are a problem, builders are slow to switch to cap fasteners because the options can be confusing.

Cap primerCap fasteners are 1-in.-dia. or larger plastic or metal disks fastened with nails or staples. A cap’s size increases the surface area under the head of the nail or crown of the staple. A larger surface area means less chance for tear-through, even in windy conditions and under foot traffic. The caps also protect underlayment and housewrap from the tool driving the fasteners, be it a hammer, a nailer, or a stapler. The original cap fastenersThin galvanized-steel disks, often called tin caps, have been around for a long time. They commonly range from 1 in. to 3 in. in dia. and are fastened with a hammer tacker or with roofing nails or staples. A hand-driven optionPreloaded caps and nails are also a widely available option, but they limit the speed of installation. They’re bulky, too, so there’s a limit to how many will fit in a nail pouch. Collated capsNowadays, there is a shift toward collated caps, which are packaged with their compatible staples or nails for installation with a designated tool. The method of collation varies, but for a package of 1600 to 2200, prices run between 1.5¢ to 2.3¢ per cap and fastener. Buying in larger quantities offers more savings, and in general, nail packs cost a little more than staple packs. |

The case for caps is strong

Caps hold the house wrap and the underlayment better than staples, they reduce the chance for tears in windy conditions, and they protect the membrane from the nose of the fastener installation tool.

Hammer tackers can cut through house wrap and underlayments when you whack the steel nose against wall or roof sheathing. Synthetic underlayments and house wraps are generally tougher than the tar paper and building paper they replace, but they are still vulnerable to punctures, tears, and stretching around the staple legs.

Although the resulting holes are small, they will leak — and that’s the rub. Many common building materials and building systems today are less forgiving of moisture than those used 50 or more years ago. Even vapor-permeable house wraps may not diffuse moisture that leaks in through holes fast enough to keep rot at bay.

It’s not just leaks, though. Most manufacturers have tested their synthetic underlayments to see what it takes to keep sheets in place and safe to walk on. The thin, narrow-crown staples used in a hammer tacker easily tear through the materials, especially under windy conditions.

And one last thing that raises the bar for professionals: Insurance underwriters often deny claims when negligent work is the root of the problem. When an installer disregards house wrap and roof-underlayment manufacturers’ explicit instructions, the insurance company may not mop up the mess.

Tools come in a few flavors

Installing cap nails by hand is the most accurate approach. It’s slow going, though, and nails preloaded with caps are bulky. There’s a limit to how many fit in a nail pouch. Collated caps and fasteners automatically feed to the nose of a tool, so all you have to do is pull the trigger.

You need to consider several factors when you’re choosing a cap tool. Some manufacturers require caps to be fastened with nails and prohibit staples, and others specify the minimum length of the fastener, regardless of type. The way in which caps are collated and fed is what dictates the size, shape, and balance of the tool.

Cap-packin’ hammer tacker

National Nail’s CH38 (shown here, about $50) has a manual cap-feed trigger. Squeeze the trigger to advance a cap, and whack the roof or wall like you ordinarily do. If you just need a staple for a temporary tack, skip the trigger squeeze. You quickly develop a rhythm: squeeze-whack, squeeze-whack. It’s not quite as fast as the continuous whacking of a regular hammer tacker, but it’s still faster than hand-driving caps and less expensive than a pneumatic model. National Nail also makes the CH38A (about $60), which has an autofeed cap design where each whack of the tool advances the cap for the next whack. I found the tool has one major weakness, though: The shear that is supposed to separate the plastic cap you just fastened doesn’t always cut clear through. When the tool is lifted off the wall or roof, a string of caps often unreels from the tool. |

In-line, sometimes called stacked-cap, tools have the most compact design. Side-mounted cap cylinders load quickly, but they can be an obstacle when nosing in to corners. Coil-cap magazines have a larger capacity, but they are slower to load and are less convenient to carry in a tool belt.

Your choice of tool also may be driven by other uses. Cap fasteners are great for attaching rigid foam, vinyl-siding backer panels, and rain-screen membranes, and the thickness of these materials warrants a tool that can accommodate long fasteners. Some tools also have shunt switches, which disengage the cap-feeding mechanism and allow you just to drive fasteners. Even without a shunt switch, you can unload caps and just fire nails or staples.

Pneumatic Cap NailersThe main advantage of cap nailers is the extra length over staples, enabling you to install rigid-foam panels. Also, some synthetic-roof-underlayment manufacturers prohibit the use of cap staples, so these tools may be your only alternative to hand-fastened caps. They are also written into the 2012 code as a requirement for high-wind areas. For heavy-duty use There are four cap nailers, and each uses coil nails ranging from 1 in. to 21⁄2 in. Each is unique in performance and capacity. The Pneu Tools RC-200 (about $235) has the same cap magazine as some of the 20-ga. staplers, but is the weakest performer of the four nailers. It has trouble sinking 11⁄2-in. nails through 5⁄8-in. OSB roof sheathing. The Bostitch N66BC (about $310) easily drives 21⁄2-in. nails, and it can double as a sheathing and siding nailer when you empty the caps. You’ll need to dial down the depth of drive so that the nail heads don’t blast through the caps, especially when installing soft foam sheathing. The 300-count nail coils correspond 3:1 to the 100-count cap strings, which take only a couple of seconds to reload. On the downside, these tools are all pushing 6 lb., which makes for tired arms when installing housewrap on standing walls. Hitachi’s NV50AP3 (about $450) weighs just a little less than the Bostitch, but is better balanced and feels much lighter. At 350 caps and an equal number of nails, the Hitachi has the largest capacity. It’s also the fastest coil-cap tool to reload. The coils are cardboard-sided, so they must be kept dry to avoid problems. The Hitachi also accepts coils of steel caps, which are required for roof underlayment in some parts of the country. A newcomer to the market, National Nail’s CN100 ($320) drives the minimum code-required cap nail for any roof underlayment (felt paper included) in high-wind zones and satisfies manufacturers’ criteria that require cap nails instead of cap staples. The trade-off is that this tool shoots only 1-in. nails—nothing shorter, nothing longer. Best betI like the Hitachi coil-style cap nailer the best. It’s reliable, has a high capacity, is quick to reload, and has perfect balance. However, if you intend to install rigid foam greater than 11⁄2 in. thick or occasionally want to use the nailer to fasten sheathing or siding, the Bostitch would likely be a better option. |

Mike Guertin (www.mikeguertin.com) is a contractor and builder in East Greenwich, R.I. Photos by Rodney Diaz, except where noted.

Fine Homebuilding #224

Editor’s Note:

Some of the cap tools in the article have been updated and improved, some have been discontinued, and there are new models on the market.

Here’s a mostly-complete list of what’s on the market in 2020:

To view the entire article, please click the View PDF button below.