Give a Custom Look to a Common Sink

You can mount an inexpensive sink under a laminate counter if you cast an epoxy rim.

Synopsis: Undermount sinks are often budget busters. The sinks, themselves, are more expensive than standard sinks, plus they typically require a solid surface such as granite for installation — another common budget buster. Inexpensive self-rimming sinks, however, can be mounted under any laminate countertop; all it takes is the know-how, and author, engineer, inventor, boat builder, and woodworker Steve Lockhart shares it all in this article. Learn how to achieve the same look for less, and enhance the custom look even further with Lockharts time-tested tips.

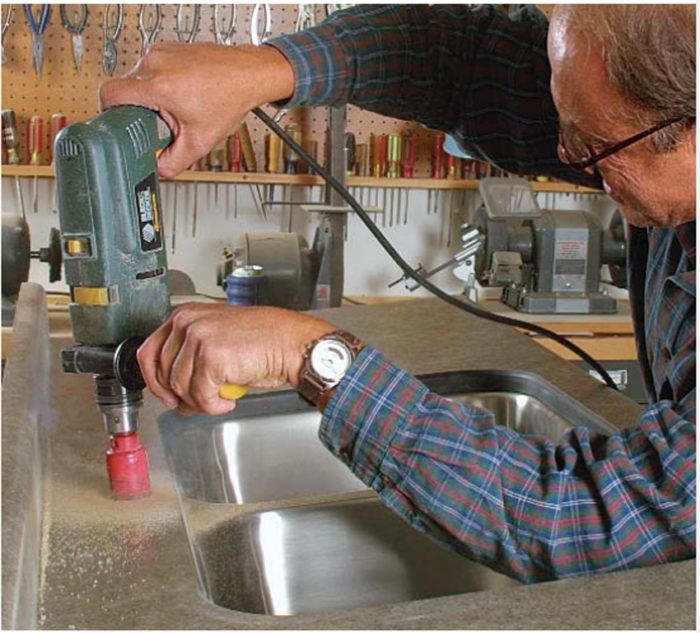

People like undermount sinks for their good looks and ease of cleanup. They’re more expensive than standard sinks, though, and they typically need to be installed in expensive countertops such as granite, solid surface, or butcher block. I combined my skills as an engineer, inventor, boat builder, woodworker, and ultra cheapskate to devise a way to mount an inexpensive self-rimming stainless-steel sink under a laminate countertop.

The process involves casting an epoxy rim into the countertop to which the sink mounts. The rim protects the cut edge of the laminate counter, and it looks great to boot.

A sink-shaped template for the epoxy channel

I use 1 ⁄4-in. hardboard to make a template for the sink cutout. The template should be 7/16 in. wider on each side than the sink cutout to allow room for a bushing and router bit. This extra space will place the inner edge of the epoxy channel just inside where the sink will be. After the epoxy sets up, I trim the rim to its exact size.

I used to use coffee cans and other miscellaneous objects I had lying around to approximate radii for templates, but I’ve come up with a better method: I trace the sink’s contour exactly on masking tape applied to the sink where the epoxy rim will be. I then move the tape from the sink to some pattern stock and measure the radius.

I cut the template carefully because it steers the router. For the straight cuts, I use a straightedge to guide the router. For the rounded corners, I cut inside the line, then sand to the line with an oscillating spindle sander.

Use the sink to place the template

In my own kitchen, I laminated the counter, but as the step-by-step photos attest, the undermount process will work with post-formed countertops, too; just raise the template to the height of the counter’s rim.

Placing a sink is easy on a post-formed countertop. With the counter flipped top down, slide the sink against the counter’s front lip. Position the sink side to side wherever you want it, then mark its outer edges. Use these marks to line up the template.

To seat properly, the epoxy rim must protrude below the counter’s bottom. About 1/4 in. is plenty. To get this extra 1/4 in. of epoxy, you need to build up the counter’s substrate, then rout the channel through both the dam and the counter.

Because the channel for the epoxy is cut with a router, some support inside the sink cutout area helps accuracy tremendously by allowing the router to sit flat. Tipping the router by mistake can send the cutting bit off the right path and you back to the lumberyard for a new countertop. I use the leftover template cutout (which I cut down further) and raise it up with more 1x scraps to the same height as the template.

For more photos and information on how to install a stainless-steel sink under a laminate countertop, click the View PDF button below.