A Small House That's Designed to Float

A 433-sq.-ft. houseboat showcases nine strategies that can make any small house live large

On a typical morning, the closest traffic passing by Michael and Charlotte Green’s house is a brood of ducks paddling toward Ross Island to forage. Michael and Charlotte live on the Willamette River—literally.

After raising a family on Bainbridge Island, Wash., the Greens decided to try something completely different. Following their discovery of a tightly knit little community of house-boaters on the outskirts of Portland, Ore., they concluded that life on the water promised a closer connection to the natural world, freshwater breezes, and constantly changing daylight bouncing off the water.

Their part of the community’s dock includes anchorage for two vessels, one on each side of the dock. The main house, which will be about 2150 sq. ft., will occupy the channel-side mooring. The guest house shown here is tied up on the riverbank side.

The Greens and I had to work with the marina’s stringent guesthouse rules, which restrict the size of the float that supports the house to no more than 18 ft. by 34 ft., with a maximum height of 15 ft. 6 in. above the water line. The fire department requires access on all sides of a structure, and with the inclusion of an exterior deck, we had a scant 14 ft. 9 in. by 22 ft. 6 in. for the home’s footprint. That’s not much room for a house with a kitchen, a bathroom, a dining area, a sitting space, and a sleeping loft.

Still, I really enjoy the challenge of designing a house that packs a lot of function and style into a minimum amount of space. A few years ago, my article in the annual Houses issue of Fine Homebuilding, “Big Ideas for small Houses”, presented 10 strategies from a variety of projects that can inject maximum utility and character into a small house. This house puts nine of them to work in one project. You can find multiple examples in each of the photos shown here.

The houseboat marina is in a part of town that has industrial buildings and warehouses scattered along the shore. We followed that lead with finishes that range from simple to rustic. Painted cedar siding, aluminum windows, and a galvanized-metal roof echo the local decor. Inside, birch-plywood built-ins, a galvanized-steel kitchen counter, and rough-sawn fir floors continue this straightforward tone. In a nod to the rippling surface of the river, corrugated-steel panels play across the ceiling.

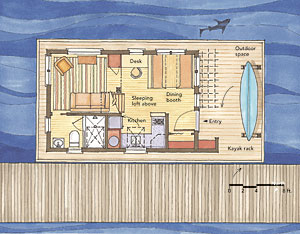

A SHIPSHAPE PLAN FOR DOCKSIDE LIVING

It’s pretty much one room, but divided into distinct zones by partitions and built-ins, this little house generously serves multiple functions without wasting a square foot.

1. Include an outdoor room

Bordered by the house and the kayak rack, this little deck (top photo) has definite boundaries that give it a room-like sense of enclosure. It simultaneously adds living space and extends the views from inside.

2. Organize the house into zones

Drawing distinctions between different parts of the house based on their function will create the impression of multiple rooms. You can do this with built-ins, ceiling-height and floor-level changes, or different finishes. Although no doors separate them, this house has distinct zones for entry transition, kitchen, dining area, living space, office, and sleeping loft.

3. Include multi-purpose rooms

The living-area couch pulls out to double as a guest bed.

4. Create long views in all directions

We used windows on at least two sides of each zone to provide views and daylight. This variety invites unconfined eye-wandering to stretch the space.

5. Use contrasts in light and color

Light colors on walls and ceilings give a room an open feeling, and sources of daylight at the end of a room draw the eye, expanding the sense of space. During the day, the corrugated-metal ceiling constantly changes with the angle of the sun. At night, spotlights play across the rippling surfaces, emphasizing the high ceiling.

6. Make the space feel tall

High windows, skylights, the vaulted ceiling, and the open ship’s ladder all promote long views to the skyline.

7. Use thick edges and built-ins

Thick edges, such as the partition wall in the loft, give the impression of strength and durability—a good trait in any house. Built-ins, such as the dining booth and the red storage cabinet, always make the most of their space, and they can serve as boundaries that define specific zones.

8. Make some things big

The oversize window in the living room evokes a sense of grandeur. In the bath, the 3-ft. by 5-ft. skylit shower isn’t huge, but it’s far more generous than the typical elbow-squeezed stalls often found in tiny houses.

9. Invest space in transitions

The sheltered outdoor closet and tiny vestibule just inside the door impart a sense of passage from outside to indoors. It’s a subtle but important element that implies a larger structure. The 6-ft.-tall partition between the door and the galley kitchen is both display space and storage on the kitchen side.

A FOUNDATION THAT FLOATS

At a time when it looked like the surrounding forests were infinite, Oregonians built their houseboats atop raft like floats made of choice logs. Times have changed. Today, there are two good reasons to take a different approach to building a float for a houseboat: Good logs are getting harder to find, and the logs will eventually need replacing as they rot along the waterline.

The state-of-the-art float supporting the Greens’ guest house is made of 4-ft.-thick expanded-polystyrene blocks encased in an 8-in.-thick shell of reinforced concrete. Unlike log floats, concrete floats are engineered specifically for the structure they will carry. And unlike log floats, they require little to no maintenance and should last at least 80 to 100 years.

Channels carved into the foam blocks accommodate plumbing and electrical lines, and exit the shell at hookup locations on the sides of the float. The topping slab includes a 6-in.-wide stemwall with anchor bolts for tying the building’s walls to the float. Point loads such as columns bear on concrete piers that go in holes hogged out of the foam where necessary.

Smaller floats like this one often have “ballast tanks” for adjusting the height of the float. These are basically air pockets that are constructed under the float. The guest-house float has four ballast tanks, one at each corner. Adding some pressurized air to a ballast tank lifts the corner; releasing the air drops it back down.

This float measures 34 ft. by 18 ft., and cost $43,000. At $70 per sq. ft., that’s an expensive foundation. But it responds to a demand rarely made of other foundations: Be strong, stable, and lighter than water.

SPECS

Bedrooms: 1

Bathrooms: 1

Size: 433 sq. ft.

Cost: $320 per sq. ft.

(doesn’t include float)

Completed: 2008

Location: Portland, Ore.

Architect: Russell Hamlet

Builder: Even Construction

Russell Hamlet (www.studiohamlet.com) is an architect based on Bainbridge Island, Wash. Photos by Charles Miller, except where noted.

View Comments

Nice house. Having lived on floating homes in the Portland area since 1991, I find them far more interesting than stationary houses. A house that moves is alive, a house that is bolted to a foundation buried in the ground is a sad, dead thing.

Floating homes also offer the opportunity to be unique and creative - as this designer has done.

One thing I'm not sure I agree with is the float. A log float with steel I-beam stringers will last at least 70 years and then it can be repaired. A float with a lifetime of only 80 to 100 years would seem to be a disadvantage. I'm skeptical that a concrete float would be truly maintenance free during that timeframe, but even if so, once it breaks you toss the whole house.

Concrete floats were popular in the Portland area in the 1990s, but all of the new houses that I see built on my stretch of the river are on logs. Our own house was re-logged in 2007 - mainly because the original logs were old used boom logs when the float was first built and they should never have been used at all. If I remember correctly, current building codes require a log that is 16" diameter at its small end. Kept low in the water, that log will last a very long time.

Leveling on a log float is done by putting "barrels" of foam at carefully selected locations. The foam floats up and lodges between the logs. It is pushing upwards with a force of over 600 pounds, so they stay put pretty well. I'm willing to bet that those ballast tanks are a lot less reliable. They would have the advantage that a diver is not required to level the float when necessary.