Q:

In a seismic retrofit (see “Protect Your Home With a Basic Seismic Retrofit,” FHB #222), are there alternatives to trimming the mudsill flush with the studs? For example, blocking between all studs provides a flat nailing surface for the plywood’s bottom edge. If adequately attached to the mudsill, wouldn’t this blocking provide a strong continuous connection for the plywood shear panel to be nailed to? Also, subfloors are stronger when both nails and construction adhesive are used to build them. Is it overkill to do the same for shear panels to increase their overall strength?

Jim Nichols, Pacifica, CA

A:

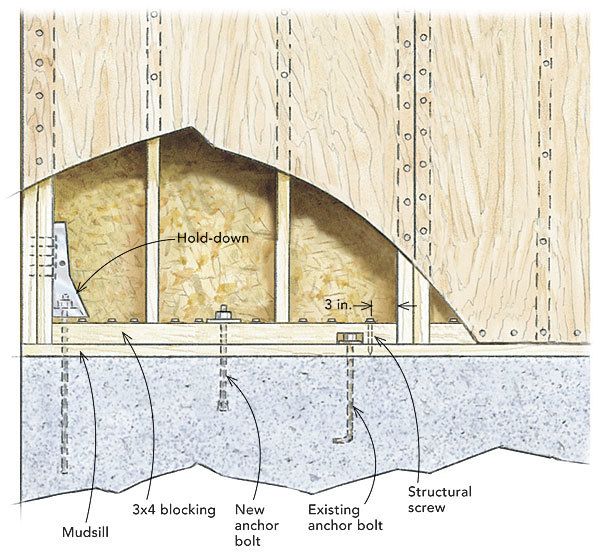

Structural engineer Thor Matteson responds: Adding blocks to the mudsill to provide a flush surface for plywood attachment must be done with great care. I have seen an assortment of bad installations of mudsill blocks. When there are many ways to mess up something, I look for another solution. Because the flush-cut method requires special—and rather dangerous—tools, I occasionally provide designs that use mudsill blocks. Keep the following in mind:

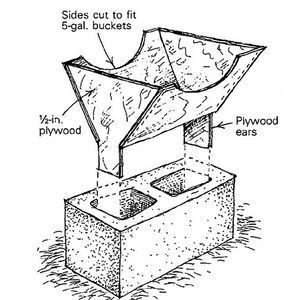

• Use 3×4 blocks to reduce the likelihood that they will split (3×6 blocks for walls with 2×6 studs). When you use mudsill blocks on an exterior wall, you have no way to check if the blocks have split when you nail the plywood panels to them from inside the crawlspace.

• Connect the blocks to the mudsill with self-drilling structural screws such as Simpson’s SDS25412 or United Steel Products’ WS45. If you drill 9?64-in. pilot holes, you can also use 20d common nails for the connection. Keep screws 3 in. from ends of members and nails 21?2 in. from ends. For 16-in. stud spacing, connect each block with three screws or four nails.

• To accommodate an existing anchor bolt, try to replace the washer with a square plate washer, cut off any length of anchor bolt that is above the nut, and notch the underside of the blocking.

• For additional strength, use construction adhesive under the blocks.

• Once you’ve connected the blocks to the mudsill, drill through both members to install foundation anchors with 3-in. square washers. (If you do not connect the block and mudsill together and rely only on the foundation anchor, you have an unsecured shear plane between the mudsill and the block.)

• If possible, cut the bottom 21?2 in. off one or two consecutive studs, then slide the blocks under the cut studs. Thirty-in.-or 46-in.-long blocks will resist splitting much better than 14-in.-long blocks.

• Use hold-downs at the ends of shear walls to help keep the blocks from splitting due to uplift forces exerted on them by the shear panels. Do not use construction adhesive to reinforce the plywood to the studs. Using adhesives creates a stiffer structural system, along with what engineers consider a brittle connection. In this case, brittle refers to a connection that will fail suddenly Adhesives are prohibited for shear-panel connections in earthquake-prone areas (section 4.3.6.3.1 of the Special Design Provisions for Wind and Seismic, the standard referenced by the IRC and IBC). In areas with low seismic risk, glued shearwall systems must be designed for much greater earthquake forces because of their greater stiffness. The nails in a shearwall system absorb a tremendous amount of energy as they flex back and forth during an earthquake. Gluing the plywood to the studs prevents this flexing until the adhesive fails, which usually happens suddenly. You want the shear-wall system to absorb the energy from the earthquake; if the plywood is attached with adhesive, the energy is transmitted to other parts of the house. In an older house, the energy transfers to weaker original construction and materials above the shear wall.

Let me explain why I just suggested using adhesive for connecting blocks and why it is allowed in flooring installation. The shear-wall plywood needs to have ductile connections. Gluing blocks to the mudsill does not prevent the shear wall’s plywood from flexing.If we think of the blocks as becoming part of the mudsill itself, it makes sense to add adhesive. It is true that a more flexible subfloor installation would perform better in earthquakes. However, we value other performance factors the rest of the time: floors that are less likely to squeak or bounce, for instance. Using glued-andnailed subfloor systems teamed with nailed-only plywood shear walls is a good compromise.