FlatLOK screws for Built-up Beams, Girder trusses and more

FastenMaster's new FlatLOK screws are designed and sized to connect multiple layer engineered and dimensional wood members

I’ve used all of the FastenMaster structural wood screws at one time or another and figured the company had the structural screw category covered. Recently when visiting their website I saw a new screw – the FlatLOK. On first glance it looks like a thicker version of the HeadLOK screw. The FlatLOK has a similar features and it designed specifically to fasten wood plies together – like LVL or dimensional headers and beams, and gang together multi-ply girder trusses. Like a HeadLOK, the FlatLOK has a broad flat head and recessed Torx drive recess.

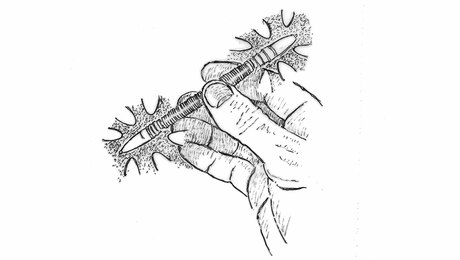

The red color differentiates the new screw from other FastenMaster screws as do the screw threads. The tip has one short narrow spiral thread then a space with a stubby pair of wings stamped on the shank before the regular threads continue about half-way along the shank. The short thread is for quick bite into the wood and the wings help clear wood fibers a little before the structural threads enter the wood. This helps the screw drive into the dense LVL without bogging down.

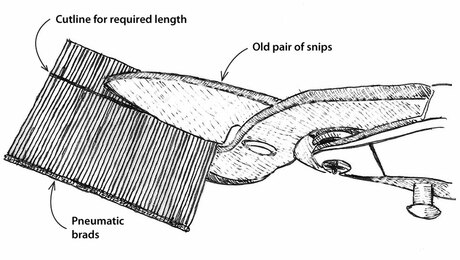

The screw lengths are matched to dimensional and engineered thicknesses so you can drive screws from one side and thoroughly engage the outermost member on the opposite face without the tip poking through. For instance, the 5 in. FlatLOK is designed to screw together three plies of LVL (5 1/4 in.) And the threaded and smooth sections of the screw shank are sized so the screw draws members together without excessive force.

We used FlatLOK screws to build up a triple LVL center beam on our current job. The screws sucked together the plies without overtaxing the impact driver. We drove about 40 screws on one battery charge and the driver still had plenty of life left in it. The screws did have a hard time penetrating the dense veneer layer of the MicroLam LVL. But once the threads engaged the wood the screws zipped in. After trying a couple of ideas to eliminate the slow initial bite we settled on a moderate hammer whack on each screw to assist. That’s all it took to work the initial penetration.

If you’re using FlatLOK screws for built-up engineered lumber beams, check out FastenMaster’s “Multiple Member Engineered Wood Beams” technical bulletin. It shows cross-sections of various combinations of engineered wood thicknesses and matching screw length, minimum screw spacing requirements, minimum edge and end distances and other information. They also include information on side-loaded beams.