Deck Bracket Design Tips

Maine Deck Brackets, or MDBs, work great in many situations. They allow the deck framing to stand off the wall, simplifying waterproofing measures and limiting thermal bridging, especially in a situation like the FHB House, with continuous exterior insulation. I first used MDBs almost exactly 20 years ago, on a house I was helping my now-father-in-law build. Since then I’ve spec’d or used them several times and have learned a few tips:

1. Double “ledgers.” Conventional ledgers need to be connected to the wall at close intervals in order to adequately handle what engineers call gravity loads: the combined weight of the building materials plus partygoers and/or heavy snow. When you install the ledger away from the house using MDBs (or other spacers), the member is no longer a ledger—now it’s a beam, and needs to be sized accordingly, following prescriptive or custom calculations for deck beams. (The company recommends using a registered design professional, and installing brackets no more than 8 ft. on center.)

(MDB image)

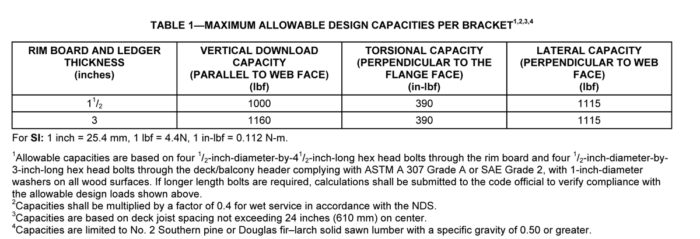

2. Use enough brackets. Each bracket is rated to carry a certain amount of weight, which varies depending on the substrate. With a 1-1/2-in. rim joist, the rated capacity is 1000 lb. per bracket. If the rim (and “ledger”) are 3 in. thick, the capacity increases to 1160 lb. per bracket.

(MDB image)

(FHB image)

3. Brackets are not lateral connectors. You still need to connect at least two joists securely to the house as insurance against the deck pulling away from the house after the wood has broken down and fasteners may have corroded. On the FHB House, we used Simpson Strong-Tie’s DTT1Z connector.

4. Prevent galvanic reaction. The brackets are tempered aluminum, and the MDB website says that 1/2-in. galvanized bolts have been used successfully, with no reports of significant corrosion after 10 years. You may think that stainless-steel bolts or lags would be preferable, but if you look at a galvanic-reaction chart, which shows how strongly different metals react with each other (by combining dissimilar metals, you’re essentially making a battery), you would see that zinc and galvanized-steel fasteners are actually less prone to react with the aluminum than stainless-steel fasteners would be. Type 410 stainless isn’t recommended for use with aluminum at all, and other types (304 and 316 being the most common) increase the risk of reacting with the base metal (aluminum). Also, when using copper-treated lumber, you should use an isolation membrane (such as a piece of Vycor) between the bracket and the lumber.

For more information on the Maine Deck Bracket, check out their website.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

100-ft. Tape Measure

Magoog Tall Stair Gauges

Stabila Classic Level Set

View Comments

Can you remove the Pinterest icon? It's blocking the photo so we can't see the full photo. I'm assuming that bracket has a bolt that goes through into the inside of the house structure. Can't tell for sure.