Don’t Compromise Luxury Finishes with Sub-par Subfloors

How subfloors can help create quiet, stiff floors.

Sponsored by AdvanTech

When it comes to home building, it’s not just the construction timeline and bottom line driving product selection. When you commit to building a finished product that provides a comfortable home for years to come, it influences small and large decisions along the way. Though subfloor isn’t always seen as a crucial element to a home’s longevity, it’s a part of the home that is “used” every day and can affect how a home feels. AdvanTech flooring – used in Fine Homebuilding magazine’s FHB House – is a unique subfloor choice offering an unmatched combination of moisture resistance with high strength and stiffness for a flat, even base for finished floors that stay quiet no matter what the jobsite or life of the home brings.

When it comes to subfloors, you may assume there are two choices – plywood and traditional oriented strand board (OSB). But ask a builder about the difference between these traditional subfloor materials and AdvanTech flooring, and you may think there is a third categorical option. Unlike plywood and commodity OSB panels, AdvanTech panels use an advanced moisture-fighting resin technology that provides moisture resistance throughout the panel to protect against swelling, cupping and delamination. This minimizes the need to sand or replace subfloor panels during construction, which can save builders time on the job. Plus, the product is backed by a 500-day no-sanding guarantee.

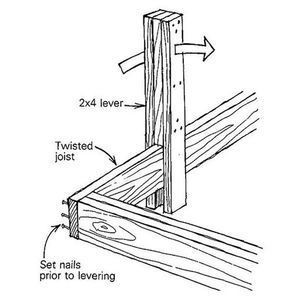

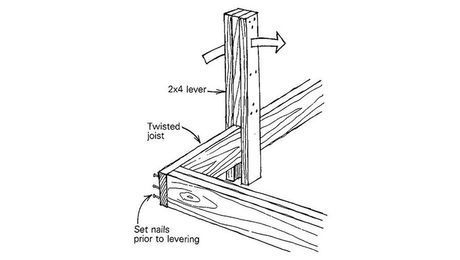

Pesky floor squeaks are often caused by differential movement – or two materials like a subfloor panel and joist rubbing against each other. AdvanTech flooring is made with high wood density to help grip fasteners in place and keep floors flat. In fact, they are the only structural wood panels with third-party documented values for higher strength and stiffness values above industry standards. See the Evaluation Service Report, ESR-1785, published by the International Code Council’s Evaluation Services, for specific values. Pairing these high-performance panels with the polyurethane bonding strength of a spray-foam adhesive like AdvanTech subfloor adhesive, can also help reduce movement at the panel-to-joist connection and protect against squeaks over time.

North Carolina builder, Kevin Milbredt of Southern Cottage Homes has switched to AdvanTech subfloor adhesive for use with AdvanTech flooring and seen obvious results.

“My first project using AdvanTech subfloor adhesive was rocked with rain during the build cycle,” Kevin said. “But there is no movement, no squeaks – it is solid.” As AdvanTech flooring users for 11 years, Kevin said the company’s move to using AdvanTech subfloor adhesive is “a no brainer.”

When AdvanTech panels and subfloor adhesive are used together with I-joists and deformed fasteners, the assembly even comes with a Squeak-Free Guarantee* for the panel-to-joist connection.

For more information on the AdvanTech Subfloor Assembly with a Squeak-Free Guarantee, visit AdvanTechPerforms.com.

*Limitations and restrictions apply. See SqueakFreeGuarantee.com for details.

View Comments

I'm curious. Does AdvanTech pay for this advertising passed-off as an article?

Hi! Yes, this article is sponsored by AdvanTech, provided and paid for by the company, and is advertorial content. We are working on labeling advertorial articles even more clearly; that improvement will appear on the site within a couple weeks, most likely. -- Mike Alterio, Web Producer, FineHomebuilding.com.