Makeup Air for the Range Hood

A range hood won't work well in a tight house without make-up air.

My own house is pretty tight — about 1.5 ACH50 — and when I run the range exhaust fan, I can hear air whistle in through the door gasket. The FHB House is even tighter — 0.39 ACH50 — so I knew going in that we had to make provisions for makeup air when the range exhaust is operating. Makeup air needs to be introduced into the kitchen but not too close to the range hood itself or the air will be drawn directly into the hood and the air rising off steaming pots will spill into the room instead of being sucked into the hood. But on the other hand, I am reluctant to dump makeup air into the room where it may feel uncomfortable.

I opted to run a 6-in. duct through the first floor system, alongside the exhaust duct, and terminate it in the kitchen cabinet toekick space just to the left of the range. There’s a space between the toekick and the bottom shelf of the cabinet, so air can freely flow out from the toekick area.

A 6-in. intake duct is a big hole in a tight house and one that I want to control to prevent heat loss.

So we installed an automatic mechanical make-up air damper (Broan). The 6-in. damper fits inline on the intake duct and has a small low-voltage motor that opens a gasketed damper valve. The motor opens the valve when air flow is sensed by a Venturi switch mounted to the side of the exhaust duct.

So we installed an automatic mechanical make-up air damper (Broan). The 6-in. damper fits inline on the intake duct and has a small low-voltage motor that opens a gasketed damper valve. The motor opens the valve when air flow is sensed by a Venturi switch mounted to the side of the exhaust duct.

The microwave/exhaust is ducted through a wall shared with a closet, so I installed a small snap-in access panel where the Venturi switch in mounted. That way if there is ever a problem with the switch it can be easily accessed.

The microwave/exhaust is ducted through a wall shared with a closet, so I installed a small snap-in access panel where the Venturi switch in mounted. That way if there is ever a problem with the switch it can be easily accessed.

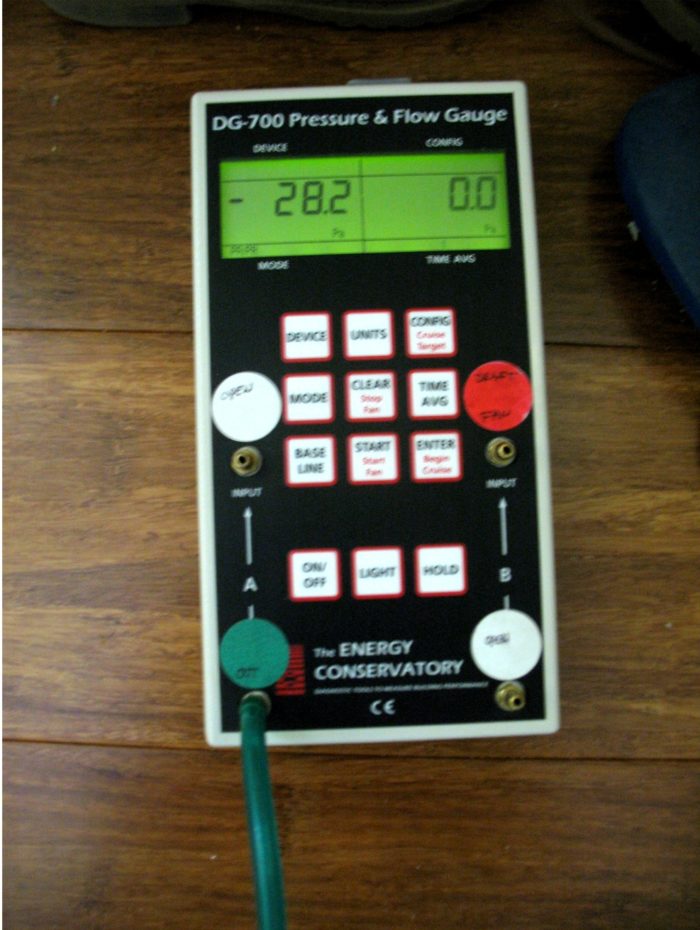

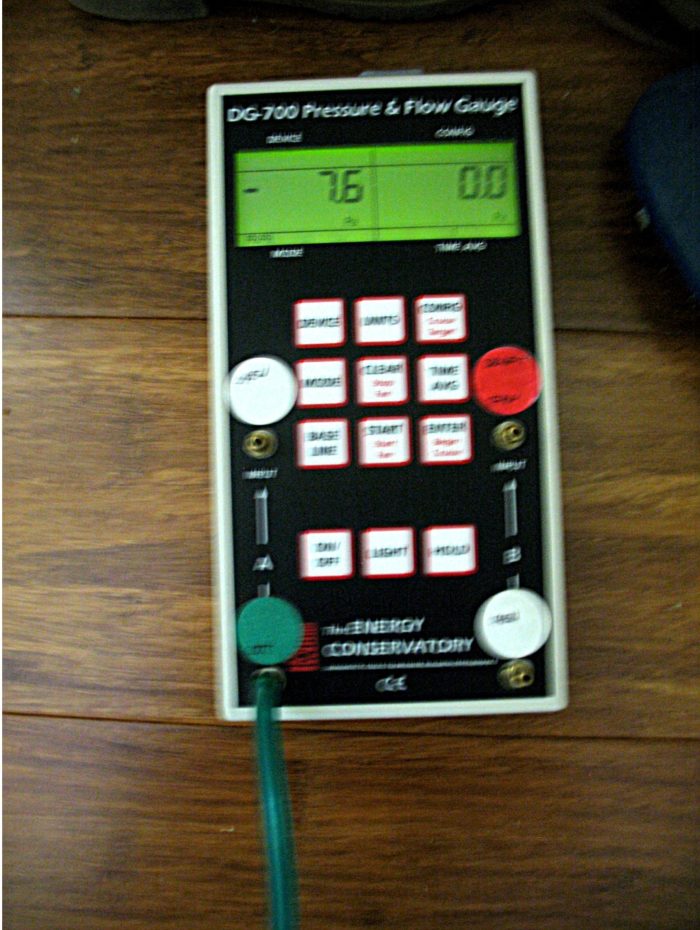

To get a sense of whether there was any pressure differential inside to outside the house when the system was operating I used a manometer to measure the baseline pressure and compare it to the pressure differential when the exhaust was operating. The baseline pressure differential was about -0.4 Pa. When the exhaust fan was turned on and before the mechanical damper opened the pressure dropped to -28 Pa. This shows that the exhaust fan was depressurizing the house quite a bit for a few seconds while the damper opened. Once the damper was fully open the pressure difference settled at -7.6 Pa. So the exhaust fan put the house under a slight negative pressure.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Anchor Bolt Marker

Original Speed Square

Smart String Line

View Comments

Hello, I was thinking of doing the same thing for make up air at my place but was concerned about bringing in cold air into metal duct and getting condensation and possible mold growth eventually. Do you believe this is something to be concerned about in a cold climate?

Reply to user 56.....

Condensation is unlikely on the inside surface of the duct in winter or summer conditions.

Condensation could occur on the outside surface of the duct in the winter figuring that the cold incoming air would chill the duct. To avoid this problem I insulated the intake duct with R6 duct wrap insulation with a well sealed poly vapor barrier. The vapor barrier prevents interior warm air from contacting the surface of the metal duct in winter so there is little chance for condensation

Why would you bother with make up air if you vent is only sucking out 101 CFM? That's tiny in comparison to todays 900 to 1200 CFM hoods. Doesn't code only require make-up air when the hood is over 400 CFM ? I understand that your manometer test showed a good impact from using the make-up air duct....but the energy penalty from bring in outside air doesn't seem worth it. I also notice that your exhaust vent is below your intake...both of which are located in a somewhat enclosed space....no concern about sucking back in the bad air you just exhausted?

The house is so tight (0.39ACH 50) that when the range exhaust fan is operating without the make-up duct open there is less than 30 CFM being exhausted. There just isn't enough air leaks in the house to provide the make-up air so in order for the exhaust fan to do its job we need to provide a duct for make-up air. There is an energy penalty whenever you operate an exhaust fan (bathroom, range) whether or not a dedicated make up air system is installed.

You are right, the code doesn't require make up air for exhaust fans less than 400 cfm.

The intake and exhaust are on the same wall and about 4 ft apart. The image doesn't show it but the area is actually pretty open. The deck ceiling above is only 5 ft. deep and the stone wall about 8 ft to open air. There may be a tiny bit of recycled exhaust air entering the intake. We were very limited when selecting locations for ducts due to the framing.

I like to bring in the make-up air as close to the burners as possible and never have it go past a person in the room. So, I deepen the countertop and bring it though a grille in the top behind the cooktop or a grille in the backsplash. Would be happy to send several pictures if you're interested.

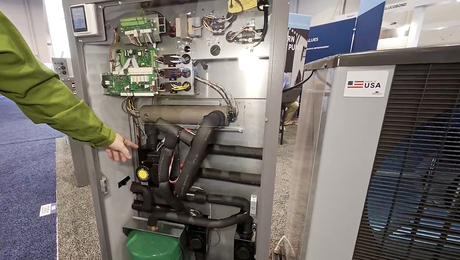

I have found from numerous makeup air installations bringing in makeup air into the return side of the heating and cooling system ductwork allows the unconditioned exterior air to be tempered before being introduced into the house. Added benefits, dedicated mechanical rooms are generally very accessible and access to the exterior from these locations is often unencumbered by finishes. We have successfully passed each and every code inspection using this method and it avoids bringing in very cold air in the winter and very hot and humid air in the summer into a room where you spend a lot of time.

At 0.39 ACH50, how did you address general ventilation? I'm rebuilding a post-fire gut-to-the-studs 70s ranch house that's going to be difficult to seal- I'll be lucky if I get 4-5 ACH50.

I'm intending to install a mini-split with baths and kitchen at opposite ends of the house. I'm thinking running those fans on a timer will probably give me plenty of ventilation, but I'm reluctant to rely on incidental make-up air, which could be coming from the crawl space or garage.

We installed a fully ducted (intake/exhaust) ERV for continuous ventilation. The exhaust fans on timers (as you are planning) can work fine but they may draw in air from the crawl space or garage just as natural ventilation would.

Great solution. AirCycler sells this exact set up (pressure switch + damper). It's meant to be paired with their whole house ventilation systems, so the damper is typically located on the return side of the air handler.

Thanks for this great write-up of your solution. I'm curious, did you do another envelope leakage test after the damper was installed? Did the 0.39 ACH50 number change?