Mixing Joint Compound

Even a "ready-mixed" compound needs some mixing before you apply it; here's what you need to know.

Joint compounds are available in powdered and ready-mixed forms. I mix powdered compounds (either setting types or drying types) with water in a 5-gal. joint-compound pail, using a heavy-duty 1/2-in. electric drill with a mixing paddle or a special mixing tool.

Setting-Type Compound

If you’re mixing a setting-type compound, it’s especially important to make sure that the pail and mixing paddle are clean, because even a thin film of setting compound on either one can cause the new mix of compound to set up prematurely. The hardened compound can also come loose and get mixed in, leaving chunks in the fresh compound.

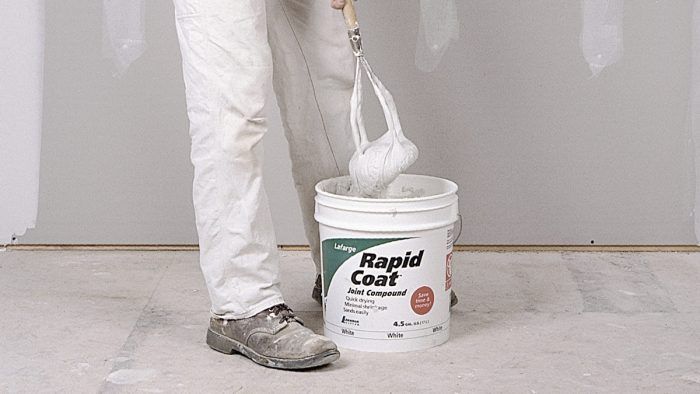

Follow the directions on the label concerning the proportions of water and compound. Pour the specified amount of cool (not cold or hot), clean water into the pail, and then add the compound. Mix until the compound reaches the desired consistency. It should be stiff enough to hold its form on the trowel (see the photos below), but not so stiff that it is difficult to smooth. Be careful not to overmix, because too much mixing can shorten the hardening time. It’s also important not to mix more compound than you can use within the specified time. Once that time has expired, the compound hardens chemically. Don’t try to remix any setting-type compound that has started to set up—it’s unusable.

| WORK SMART: Use an all-purpose or taping compound, not a topping compound, for the first coat on fasteners and beads. Although a topping compound is fine for finish coats, it is not suitable for the first coat because of potential problems with adhering. |

Drying-Type Compound

To mix “powdered drying-type compound,” add the compound to the specified amount of water and mix well until the powder is completely damp. Let the mixture stand for 15 minutes and then remix. This type of compound does not set up—it has to air dry—so it can be kept for extended periods of time as long as it’s covered. It can be remixed, if necessary.

Ready-Mixed Compound

The most common type of drying compound is called “ready-mixed compound.” If a ready-mixed compound is fresh, just a little stirring is necessary. If it has been sitting around for a while, you may need to loosen it by adding a little water. Even if you don’t need to add water, it’s a good idea to mix the compound so it has the same consistency throughout the pail. I prefer to use a masher-type mixer rather than a powered mixing paddle for this light stirring.

| WORK SMART: Overmixing with an electric mixer can whip excess air into the compound. Air bubbles in the compound can cause pitting or bubbles in the taped seams. |

Ready-mixed compounds are generally used at the consistency in which they come, but they can be thinned for taping. I often thin the compound for the third coat. Add a little water at a time to avoid overthinning (if the mixture becomes too thin, add more compound to attain the correct consistency). If the compound freezes, allow it to thaw at room temperature and mix it without adding water. If the compound has sat too long and separated so that a clear liquid forms on top, it can usually be remixed. If it smells sour or looks moldy, the compound has gone bad and should not be used.

| THINK AHEAD: If possible, go through the work area the day before you begin taping to fill any gaps larger than 1/8 in. with joint compound. You must fill the gaps anyway, and this way the compound will dry before you begin taping. |