Spray Foam Insulation in a Gut Remodel

Jon Beer discusses air-sealing and insulation strategies at FHB House New York.

Jon Beer is using a combination of open-cell and closed-cell spray-foam insulation due to varying construction types in old and new parts of Fine Homebuilding House New York. In this video, Jon details his decision to use spray foam and how he used a preinsulation blower-door test to assess the house’s airtightness before insulation and to identify areas for air-sealing.

Here’s the transcript:

I’m Jon Beer from Jon Beer Contracting. We’re back at the Fine Homebuilding House here in Cornwall, New York. As you can see, we’ve started to spray-foam.

We are mixing open-cell and closed-cell in different wall assemblies because we have two essentially different types of construction. In the old parts of the house, we have 2×4 framing with a fiberboard sheathing, and that fiberboard is not sealed in any manner. It’s pretty porous. And in the new parts of the house, which are 2×6 framing on the exterior, we’re clad with ZIP sheathing—that WRB is on the outside.

Some of you may be wondering, OK, you have this opportunity to re-insulate this house—Why choose spray foam? While I would prefer to choose mineral wool or dense-pack cellulose over spray foam in new construction, in an old retrofit situation, closed-cell spray foam is going to give us the most R-value per inch and a built-in vapor retarder in an older wall assembly that doesn’t have one.

Because we made that decision, we need closed-cell spray foam for at least half of the house. It made more sense from an efficiency standpoint to have one installer and have them foam the entire house. While spray foam is potentially questionable for the environment, for us, remodeling a house that is already built is really the lowest-carbon way to build. The building already exists, so that that carbon has already been spent. To retrofit rather than to totally build from scratch and be using all new materials, kinda negates our decision to use spray foam. That’s kind of the general plan of what product we’re using where and why.

As far as the process goes, we started with a blower-door test, preinsulation. So, the idea behind that is we wanted to set a baseline number for how tight, or not tight, the house is before insulation goes in. We spent quite a bit of time air-sealing, trying to go through all of our trouble areas. Under positive pressure, we were around 3 ACH and under negative pressure, 4.5 ACH, so both of those readings are pretty good. Our spray-foam tech told us that they’ve seen ratings of 8 to 28 ACH on house’s preinsulation.

The other bonus of doing that blower door preinsulation was that we were able to find areas that we couldn’t seal with tape, but that we could foam with the spray foam. So we had a couple spots where the new house met the old behind a header that was hard for us to get into and tape, that they were easily able to fill with foam and seal that cavity off.

The blower-door test is critical for us in that regard. It’s definitely something that I would do on another project for a client if we were doing a full gut renovation and focusing on tightness and indoor-air quality.

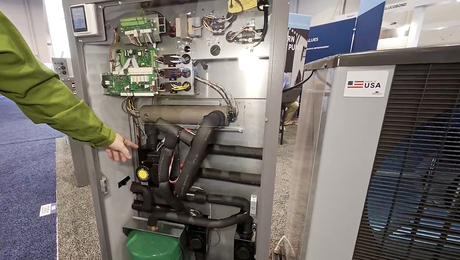

Once the blower door was complete, they started to prep. You can see everything is draped in plastic. One hot tip is don’t use staples on the floor. If you’re plasticing down, we’ve had scenarios where spray foam installers have done that and then we have a million staples to pull at the end. I had them just stable up the walls, everything is draped, our mechanical equipment and the minisplits are covered, and they started by spraying the closed-cell. You’ll also see that some of these walls are very clean looking on the framing. So one cool thing that this company did was use packing tape on all the studs. That way when the foam is almost cured, all they have to do is just pull that tape off and clean off that stud really easily and it’ll make shaving down the protruding spray foam a lot easier.

We’re rolling into day two of spray foam. We’re going to have both rigs here, spraying closed-cell and open-cell at the same time. The hope is that we’ll be wrapping up foam by the end of the day tomorrow and getting into the clean-up phase of the project. And soon after that, rolling right into sheetrock.

View Comments

Good points - but I prefer using something that’s flame resistant.

I am always a bit skeptical of a foam insulation article that doesn't mention indoor air quality, VOC potential or the flame retardant issues. Firefighters are not big fans of foam insulation.

Where was the open-cell used vs the closed-cell?

Why not use canned spray at all penetrations and then mineral wool in the bays? Is this purely an R decision? There are so many benefits to mineral wool vs foam , this seems like a reasonable trade off.